中型货车前悬架设计及分析毕业论文

2020-02-17 17:09:18

Wuhan University of Technology Graduation Design (Thesis)

Design and Analysis of Front Suspension of Medium-sized Truck

School: School of International Education

Specialty amp; Class: Automotive Engineering gj1503

Name: Li Jinrong

Tutor: Guo Huiru

Statement of Degree Thesis originality

I solemnly declare:The thesis submitted is the research result independently obtained by myself under the guidance of my tutor. Except for the contents specifically quoted in this thesis, this thesis does not include any other works that have been published or written by individuals or groups. I fully understand that the legal consequences of this statement are borne by me.

Author’s Signature:

Date:

Using Authorization of Thesis copyright

The author of this thesis fully understands the provisions of the school regarding the protection and use of thesis, and agrees that the school retains and sends copies and electronic versions of the thesis to the relevant thesis management departments or institutions, allowing the thesis to be viewed and borrowed. I authorize the provincial excellent bachelor thesis selection institution to compile all or part of the thesis into relevant data for retrieval. The thesis can be saved and compiled by photocopying, printing or scanning.

The thesis belong to 1、Confidentiality囗,Apply this authorization after the year of declassification)

2、No Confidentiality囗 .

(Please type “√” in above relevant block)

Author’s Signature: Date:

Tutor’s Signature: Date:

Summary

With the development of automobile industry, people have higher and higher requirements of riding with comfort and safety. So, the design of automobile suspension becomes more and more important and demanding. In order to improve the comfort and safety, a front suspension system with high safety and reliability is designed for a medium truck, and verified by theoretical calculation and finite element analysis.

First of all, according to the selected medium truck type: Jianghuai Gerfa K6L card vehicle parameters, the suspension type is selected as steel plate spring type non-independent suspension. Then the main components: leaf spring and shock absorber design calculation and verification. Finally, the suspension model is established, and the assembly drawing and part drawing are drawn. In this paper, the mechanical properties and stress distribution of small trapezoid variable cross section leaf spring are analyzed theoretically, and the finite element analysis is also used to verify the design of small plate variable cross section leaf spring front suspension which meets the requirements of medium freight car. At the same time, this paper shows the advantages of leaf spring of variable cross section with few plates, which will be more and more important in reflecting the fact that less sheet spring will be obtained. The more applications there will be.

Key words: Front suspension; Leaf spring of variable cross section with few plates;

Shock absorber; Finite element analysis

contents

Summary 0

Introduction 1

1.1. The function of suspension and the function of leaf spring 1

1.2 Development status of suspension and leaf spring 2

1.3 The main contents and methods of suspension design 3

Chapter 2: Overall Design of Front suspension 5

2.1 Determination of reference models 5

2.2 Structural Analysis and selection of front suspension 6

2.2.1 Non-independent suspension 6

2.2.2 Independent suspension 7

2.2.3 Determination of suspension structure form 8

2.3 determination of main parameters of suspension 8

2.3.1 static deflection fc 8

2.3.2 Dynamic deflection of suspension 10

Chapter 3 Design and calculation of leaf spring 11

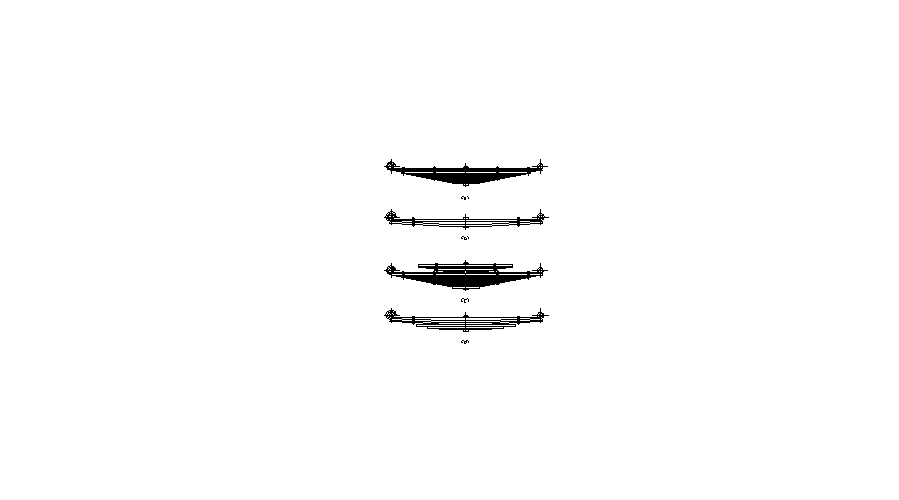

3.1 Type of leaf spring 11

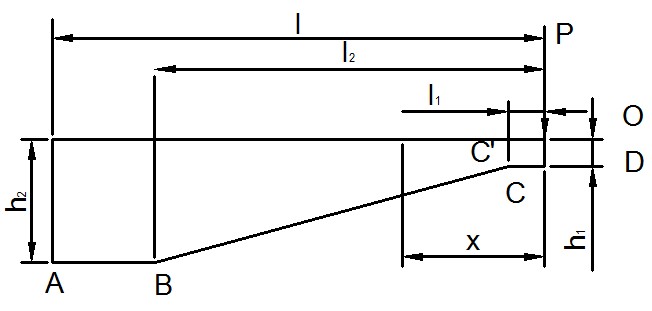

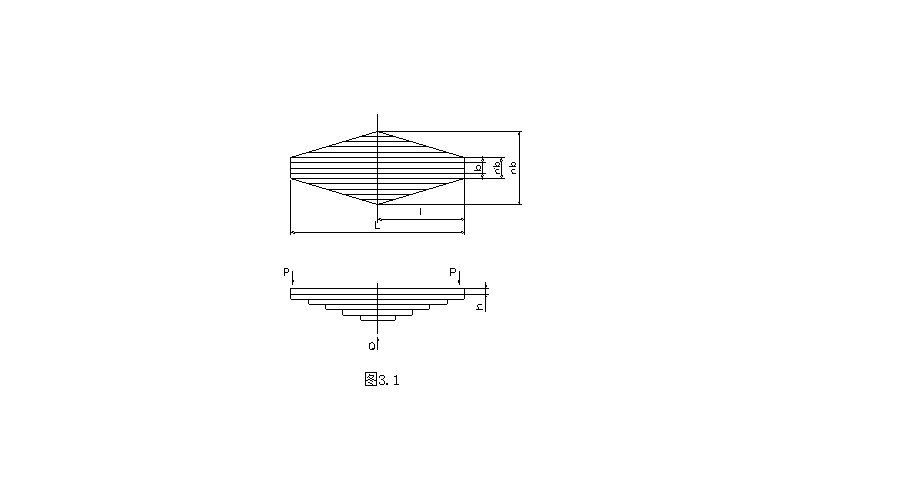

3.2 Structural Analysis of leaf spring of variable cross section with few plates 12

3.2.1 Equal stress beam and its geometric shape 13

3.2.2 Parabola leaf spring 14

3.2.3 Ladder variable cross section leaf spring 14

3.3 Mechanical Analysis of ladder variable Section leaf Spring 15

3.3.1 Stiffness of ladder spring 16

3.3.2 Maximum stress Point and maximum stress of ladder Spring 17

3.4 Layout Scheme and Section shape determination of leaf Spring 19

3.5 Selection of leaf spring materials 19

3.6 Size Design of Spring with small sheet and variable cross section 20

3.6.1 Determination ofreed length L 20

3.6.2 Calculation of average thickness and width of reed 20

3.6.3 Spring ladder design 21

3.7 Calculation of stiffness k of leaf spring 22

3.8 Maximum stress of ladder spring 23

3.9 Calculation of Arc height of small spring 23

3.10 Strength check of leaf spring 24

3.10.1 Longitudinal torsional stress check of automobile leaf spring 24

3.10.2 Strength checking calculation of leaf spring when automobile passes through uneven road surface 25

3.10.3 Strength accounting of Leaf spring winding ear 26

3.10.4 Strength check of spring pin 27

3.10.5 Checking calculation of strength of U-shaped Bolt 27

Chapter 4: Finite element Analysis based on SolidWorks 29

4.1 Selection of finite element software 29

4.2 Establishment of 3D suspension Model 29

4.3 Process of finite element analysis 29

4.3.1 Analysis of single spring 30

4.3.2 Analysis of leaf spring assembly 30

4.4 Results of finite element analysis 30

4.5 Analysis of finite element solution results 32

4.6 Conclusion of finite element analysis 32

Chapter 5: Design and selection of shock Absorber 33

5.1 Brief introduction of shock Absorber 33

5.2 Main structural types and working principles of shock absorbers 34

5.3 Selection of main performance parameters of shock Absorber 35

5.3.1 Selection of relative damping coefficient 35

5.3.2 Determination of damping coefficient δ of shock Absorber 36

5.3.3 Determination of maximum unloading Force F0 37

5.3.4 Determination of working cylinder diameter D of cylinder shock Absorber 38

5.3.5 Design and calculation of piston rod 38

5.3.6 Design and calculation of guide seat width and piston width 39

5.3.7 Determination of other size parameters of shock Absorber 39

6.1 Design of other components 41

6.2. Solidworks builds suspension model 41

Conclusion 43

Reference 44

Thanks 46

Introduction

1.1. The function of suspension and the function of leaf spring

Suspension is a general term to ensure the elastic connection between the wheel or bridge and the vehicle bearing system (frame or load-bearing body) and to transfer the load, mitigate the impact, attenuated vibration and adjust the position of the car body when the vehicle is running. The main functions of the vehicle suspension system are as follows:

(1) Ease, restrain the vibration and impact caused by uneven road surface, and ensure the ride comfort of the vehicle:

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

![D:\Program Files\QQ\1045264196\Image\]{`YDQ~HIUZU]K0CJ0AW[%P.jpg](http://www.biyelunwen.org/wp-content/uploads/2020/02/lw7450_202021717914714.png)