某中型载货车驱动桥设计毕业论文

2020-02-17 17:08:52

某中型载货汽车驱动桥设计

学院(系): 国教学院

专业班级: 车辆gj 1502班

学生姓名: 赵浜宇

指导教师: 王 超

学位论文原创性声明

本人郑重声明:所呈交的论文是本人在导师的指导下独立进行研究所取得的研究成果。除了文中特别加以标注引用的内容外,本论文不包括任何其他个人或集体已经发表或撰写的成果作品。本人完全意识到本声明的法律后果由本人承担。

作者签名:

年 月 日

学位论文版权使用授权书

本学位论文作者完全了解学校有关保障、使用学位论文的规定,同意学校保留并向有关学位论文管理部门或机构送交论文的复印件和电子版,允许论文被查阅和借阅。本人授权省级优秀学士论文评选机构将本学位论文的全部或部分内容编入有关数据进行检索,可以采用影印、缩印或扫描等复制手段保存和汇编本学位论文。

本学位论文属于1、保密囗,在 年解密后适用本授权书

2、不保密囗 。

(请在以上相应方框内打“√”)

作者签名: 年 月 日

导师签名: 年 月 日

(注:此页内容装订在论文扉页)

Abstract

The role of the truck Drive Bridge is to get the torque from the car engine. By passing the main speed reducer, differential, drive shaft and other parts to the front drive wheel of the truck, the main speed reducer will reduce the transmission speed and obtain a relatively high output torque. The main speed reducer double-sided gear pair and the bevel gear pair can change the torque transmission direction. During the journey of the truck, the drive bridge uses the differential to make the wheels on both sides of the truck produce differential effects when turning and turning, so that the 0.wheels on the outside and inside sides of the truck turn at different speeds at the same time. It realizes the function of Load and Transfer Power on the Shell Body of Car Bridge and the Wheel of Truck.

In this paper, the design of the truck Drive Bridge is carried out with reference to the design method of the traditional drive bridge. This design firstly describes the characteristics of the drive bridge, determines the overall parameters of the car according to the given data, and then determines the structure type and parameters of the main reducer, differential, semi-axis and bridge shell, and checks its strength. After the data is confirmed, a three-dimensional model is established with CATIA software, a two-dimensional model is established with CAD, and a finite element analysis of the driving bridge shell is carried out with ANSYS.

Key words: drive axle; CAD; CATIA; finite element analysis

ITEM

1 Introduction 1

1.1 introduction to drive bridges 1

1.2 status of research at home and abroad 2

1.3 design requirements for drive bridges 3

2 Drive Bridge Design 3

2.1 main reducer design 4

2.1.1 structure of the main reducer 4

2.1.2 selection of basic parameters and determination of calculated loads for the main reducer 7

2.1.3 summary 15

2.2 differential design 15

2.2.1 Principle of operation of symmetric Bevel gear differential 15

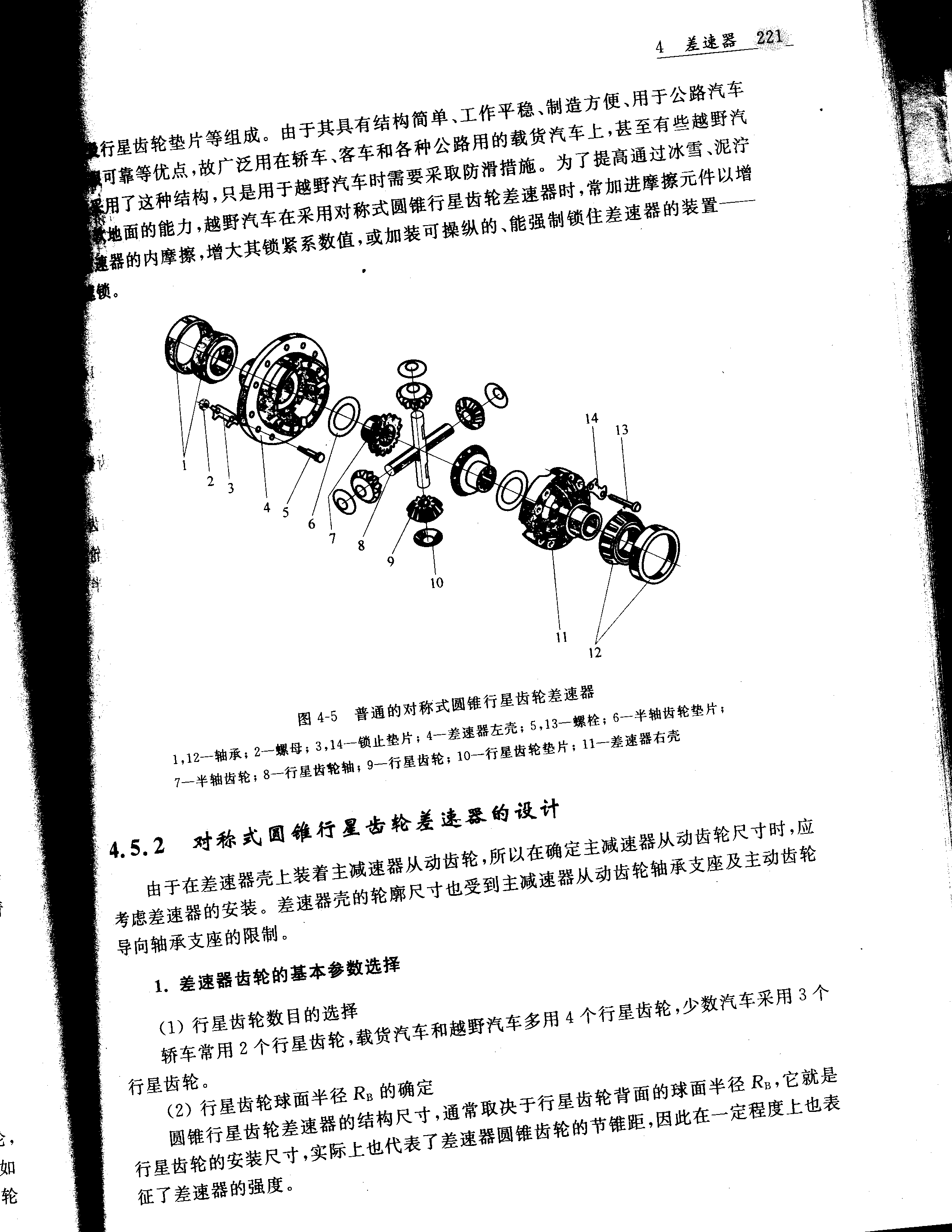

2.2.2 Structure of symmetric panicle planetary gear differential 16

2.2.3 Design of symmetric conic planetary gear differential 17

2.2.4 Summary 20

2.3 design of driving half-axis 20

2.3.1 Analysis of structural forms 22

2.3.2 Structural design of fully floating semi-axes 23

2.3.3 Strength calculation of fully floating semi-axes 23

2.3.4 Semi-axis structure design and material and heat treatment 24

2.3.5 Summary 25

2.4 design of drive bridge shell 25

2.4.1 Structure of the integral bridge shell 26

2.4.2 Stress Analysis and Strength Calculation of Bridge Shell 26

2.4.3 Summary 27

3 CATIA 3D modeling 28

3.1 introduction to catia software 28

3.2 modeling of the main reducer 28

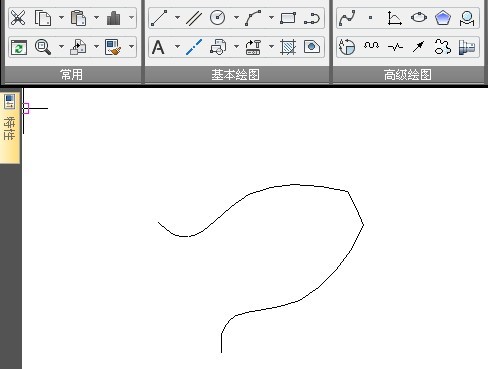

3.2.1 Three-dimensional modeling of active Bevel gears 28

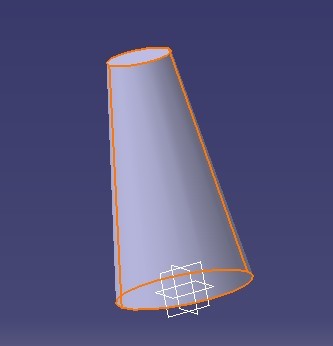

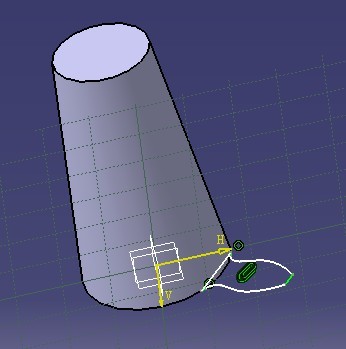

3.2.2 Three-dimensional modeling of the main reducer shell 30

3.2.3 Three-dimensional modeling of bearings 31

3.3 differential modeling 31

3.3.1 Three-dimensional modeling of gears 32

3.3.2 Modeling of half-axle gears 33

3.3.3 Modeling of slave gears 33

3.4 half-axis 3d modeling 35

3.5 three-dimensional modeling of driven bridges 35

3.6 modeling of main reducer and planetary gear 36

3.7 three-dimensional modeling of drive bridges 36

4 Finite Element Analysis of Drive Bridge Shell 37

4.1 constraints and stress analysis of drive bridge shell 37

4.2 limitations of the method of calculation 37

4.3 analysis of the static strength of the driven bridge shell 38

4.3.1 Analysis of static strength 38

4.3.2 Analysis of results 39

4.4 summary 40

Conclusion 41

Expression of thanks 42

References 43

Item

1 Introduction

1.1 Introduction to Drive Bridges

The car drive bridge is at the end of the car transmission system and is mainly composed of the main reducer, differential, half shaft and drive bridge shell. Its basic function is to transmit the engine torque from the universal transmission device to the driving wheel through the main reducer, differential, and half shaft, so as to reduce the speed and increase the torque; The transmission direction of torque is changed by the Bevel gear pair of the main reducer; Through the differential speed of the two sides of the wheel differential effect, It ensure that the inner and outer wheels with different speed steering [1].

There are two types of drive bridges: disconnecting drive bridges and non-disconnecting drive bridges. When the independent suspension is used to drive the wheel, a disconnect drive bridge should be used; When a non-independent suspension is used to drive the wheel, a non-disconnecting drive bridge should be used.

The overall task of the car transmission system is to transfer the power of the engine and adapt it to the needs of the car. In the mechanical transmission of ordinary cars, the transmission can not completely solve the contradiction between the engine characteristics and driving requirements and the structural layout problems [2]. First, because most engines are arranged vertically on cars, in order for their torque to pass to the left and right drive wheels, the main reducer of the drive bridge must change the direction of torque transmission. At the same time, the differential of the drive bridge must be used to solve the torque distribution problem and differential problem between the left and right drive wheels. Secondly, because the main task of the transmission is only to select the appropriate gear number and gear ratio so that the rotational rate-torque special performance of the internal combustion engine can meet the requirements of the vehicle's dynamic and economic performance under various driving resistance. The function of the driving bridge main reducer is to make the car have enough traction, appropriate maximum speed and good fuel economy when the transmission is in the highest gear [3]. For this reason, the power passing through the transmission and transmission shaft must be further increased by the main reducer of the drive bridge to reduce the change in speed. Therefore, in order to make the design of the car transmission system reasonable, we must first select the total transmission ratio of the car properly and distribute it appropriately to the transmission and Drive Bridge. When the transmission is in the highest gear, the dynamics and fuel economy of the car mainly depend on the main deceleration ratio. In the overall layout design of the car should be based on the working conditions of the car and the engine, transmission system, tires and other relevant parameters, choose the appropriate main deceleration ratio to ensure that the car has good power and fuel economy [4]. The optimal matching between engine and transmission coefficient can be obtained by the optimal design method. Due to the increase of engine power, the reduction of vehicle quality and the improvement of road conditions, the main deceleration ratio has a tendency to develop slightly. When choosing the main deceleration ratio, we must consider that the car can meet the requirements of high-speed driving, and it can also reduce engine speed, reduce fuel consumption, improve engine life and improve vibration and vocal characteristics within the commonly used speed range.

1.2 Status of research at home and abroad

Automobile and Automobile Industry play a very important role in the national economy, modern society and people's life [5]. In the current Chinese economic construction, the automobile is in a very prominent and priority position. In recent years, the auto industry in China's machinery industry has grown at a relatively higher rate than other industries. But the growth of the Chinese auto industry is still far from catching up with demand. Every year, a large number of various cars and their parts are imported. Due to various reasons, the Chinese automotive industry is still quite far from the international level, especially in the design and research of driving bridge products. This aspect should be recognized by many departments and companies in China.

Domestic drive bridges mostly use hoof type or disc type dry type brake, disc type brake is divided into two types: clamp disc type and total type. Compared with foreign advanced products, the domestic technology level of driving bridge gear transmission is still relatively low, and there are two main shortcomings: First, there is a certain gap between gear, shaft, shell and other parts and materials compared with foreign products [6]. There are defects such as large overall weight and volume, short service life, etc. Second, the technical performance is relatively backward, and there is generally no advanced device such as self-locking Anti-Slip differential and wet brake. The promotion of self-locking Anti-Slip differential and wet brake in the tire type engineering mechanical drive bridge is one of the ways to improve the technical level of the engineering mechanical drive bridge, and it is also an inevitable trend of the development of domestic mechanical drive bridge technology [7].

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: