华信123煅烧脱硝系统流场数值计算毕业论文

2020-07-11 18:06:12

摘 要

氮氧化物是大气最主要的污染物之一,也是各火电厂最主要的排放物之一。随着国际环境局势的进一步紧张,我国环保局发布的排放标准也日益严格,因此各火电厂改善脱硝技术以控制氮氧化物排放是势在必行。选择性催化还原技术以拥有最高可达90%的脱硝效率成为燃煤电站控制NOx的主要选择。而通过数值模拟方法可以在低成本、高效率的情况下研究SCR脱硝反应过程,优化脱硝反应装置,实现一定的科学技术价值。

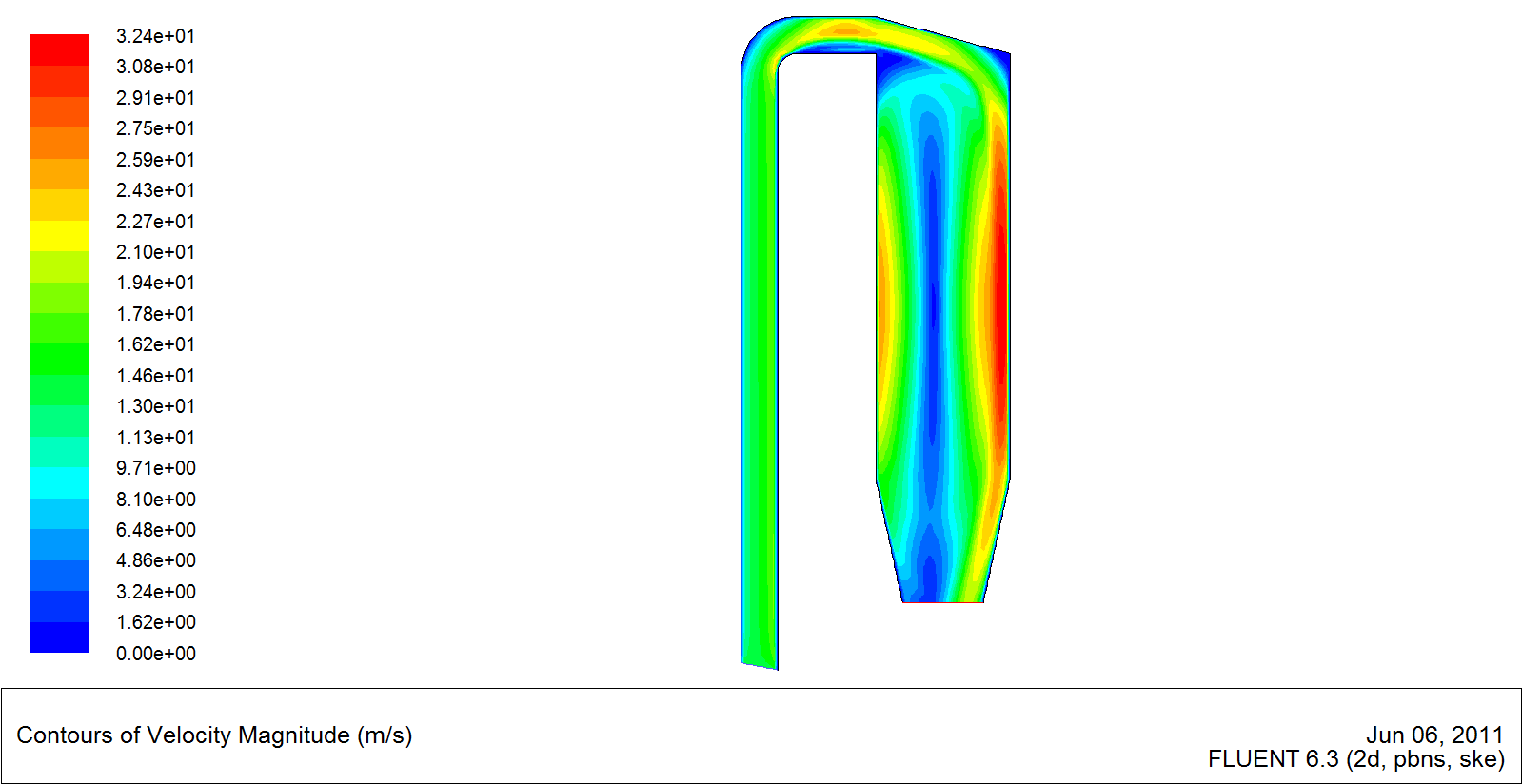

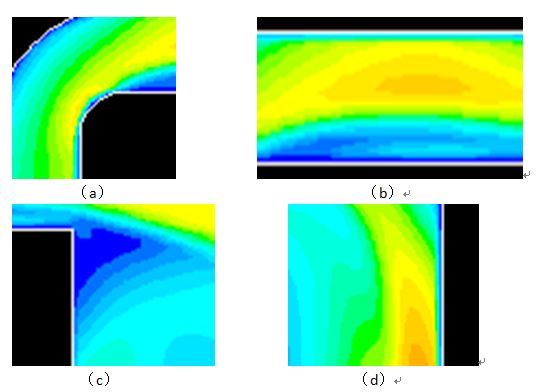

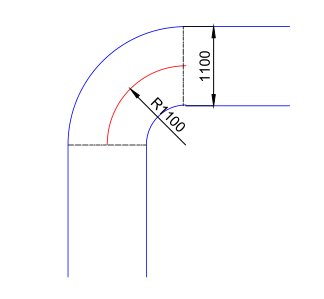

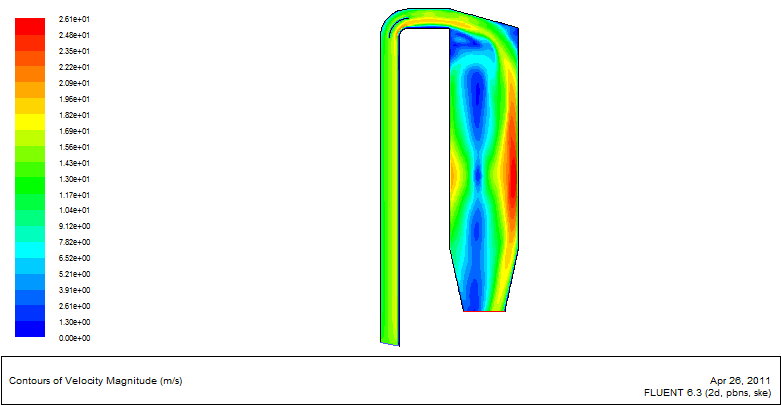

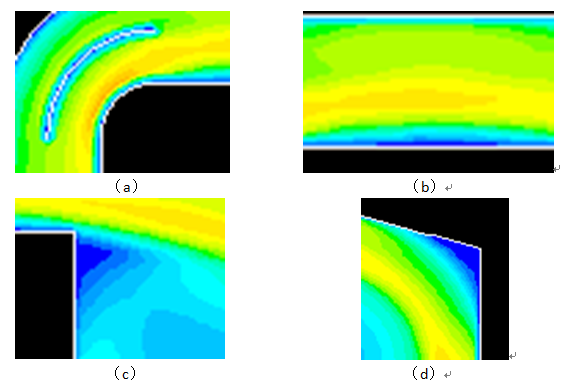

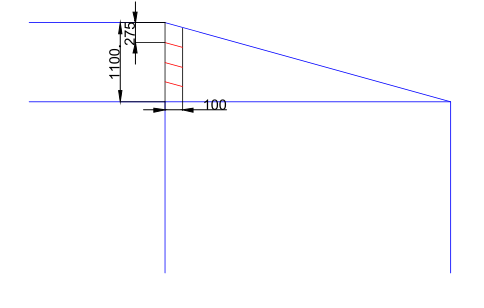

本次主要工作是以华信123煅烧脱硝系统为研究对象,建立SCR反应器数学模型,对烟气在烟道内速度及温度流场进行数值模拟,针对优化前反应器内模拟显示的低速三角区、高速冲刷区和低速回流区采用不同形式的导流板进行优化。 对于直角烟道可以采用“圆弧”形导流板,对于斜变截面处烟道可采用“平直”形导流板,经过多次优化直至烟气在烟道内均匀分布。在经过数值模拟后,反应器脱硝效率得到大大提升,也为SCR过程中催化剂制作和SCR反应器的设计提供了一定的指导。

本文还对国内外燃煤电站SCR脱硝技术发展现况进行了综合评述,分析了数值模拟过程和数学模型的原理,阐述了计算流体学CFD计算软件在SCR脱硝模拟中的应用情况。在现有技术条件下,CFD计算软件广泛应用于SCR数值模拟的各项研究,是探讨优化SCR脱硝设计最主要的方法。

关键词:氮氧化物,数值模拟,选择性催化还原,导流板

Numerical calculation of flow field of calcined denitrification system of huaxin 123

Abstract

Nitrogen oxides are one of the major pollutants in the atmosphere and one of the most important emissions from thermal power plants. With the further tightening of the international environmental situation, the emission standards issued by China's Environmental Protection Agency are also becoming increasingly stringent. Therefore, it is imperative for each thermal power plant to improve its denitration technology to control nitrogen oxide emissions.Selective catalytic reduction technology has the highest denitrification efficiency of up to 90% to become the main choice for coal-fired power plants to control NOx. The numerical simulation method can be used to study the process of SCR denitrification under the condition of low cost and high efficiency, optimize the denitration reaction device, and achieve certain scientific and technological value.

The main task of this work is the Huaxin 123 calcining and denitrification system. The mathematical model of the SCR reactor is set up to numerically simulate the velocity and temperature flow field of the flue gas in the flue gas duct, aiming at optimizing the low-velocity triangle area of the pre-reactor display. The high-speed flushing zone and the low-speed recirculation zone are optimized using different forms of deflectors.For the right-angle flue, "arc" shaped deflectors can be used. For the inclined cross-section, "flat" shaped deflectors can be used, and after many optimizations until the flue gas is uniformly distributed in the flue. After the numerical simulation, the reactor denitrification efficiency has been greatly improved, and it also provides some guidance for the catalyst production and SCR reactor design in the SCR process.

This paper also makes a comprehensive review of the development status of SCR denitrification technology in coal-fired power plants at home and abroad,

analyzes the principles of numerical simulation process and mathematical model, and expounds the application of computational fluidics CFD calculation software in SCR denitrification simulation. Under the existing technical conditions, CFD calculation software is widely used in various researches of SCR numerical simulation. It is the most important method to optimize the SCR denitrification design.

KEY WORDS: nitrogen oxides numerical simulation selective catalytic reduction deflector

目 录

摘要...............................................................Ⅰ

Abstact............................................................Ⅱ

目录...............................................................Ⅳ

第一章绪论..........................................................1

1.1研究背景和意义................................................1

1.2国内外SCR脱硝技术及数值模拟发展、研究概况.....................1

1.2.1国外SCR脱硝技术发展概况.................................1

1.2.2国内SCR脱硝技术发展概况.................................2

1.2.3内外SCR法数值模拟技术发展概况...........................2

第二章 SCR脱硝数值模拟的理论基础...................................4

2.1CFD软件介绍及应用.............................................4

2.2数值模拟方法..................................................4

2.2.1描述方程.................................................4

2.2.2模型简化及数学模型.......................................6

2.2.3模拟过程简介.............................................6

2.2.4小结.....................................................7

第三章设计方案......................................................8

第四章SCR脱硝数值模拟结果分析及流场优化...........................10

4.1烟气进口边界条件.............................................10

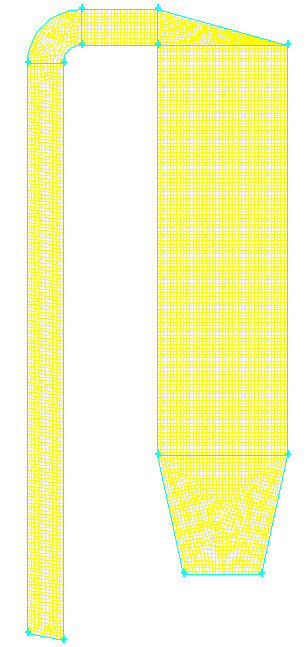

4.2网格划分.....................................................10

4.优化前流场分布.................................................11

4.4方案1优化结果及分析..........................................12

4.5方案2优化结果及分析..........................................13

4.6方案3优化结果及分析..........................................15

4.7方案4优化结果及分析(三维)....................................16

4.8小结.........................................................18

第五章结论...................................................19

5结论...........................................................19

参考文献...........................................................21

致谢...............................................................24

第一章 绪 论

1.1研究背景和意义

化石能源在我国能源结构中占有相当大的比重。特别是对于电厂,虽然各种新能源发电在近年来层出不穷,但是利用煤炭进行发电的燃煤电厂仍是我国电力供应最主要的来源。利用燃煤进行发电产生的污染是极大的,煤在燃烧的过程中会产生非常多的有害气体,氮氧化物(NOx)就是其中最为严重的污染物之一。在煤碳燃烧发电的过程中,总共会产生3种类型的氮氧化物,即“热力型”NOx、“快速”型NOx和“燃料”型NOx。燃煤发电厂烟气排放中燃料类型占据更多,占排放物的75%~90% [1,2]。

近些年来,中国相关能源部门表示氮氧化物的排放量迅速增加。2000年和2005年中国氮氧化物排放量在短短5年内增长了一倍,从每年十兆吨增长到了二十兆吨。所以说我们如果对氮氧化物污染物的排放继续保持视而不见的态度,不即时采取相应的措施的话,那么随着经济的高速发展、人口的飞速增长和城市化的发展,氮氧化物的排放量将会以无法预知的恐怖速度增长,破坏我们赖以生存的地球环境。按照现在的趋势,预测到2030年氮氧化物的排放量会达到35.3×106t,到那时一切都为时已晚。因此,必须加强控制氮氧化物的排放[3]。

相关图片展示: