管壳式换热器的性能评价分析毕业论文

2020-06-19 22:19:18

摘 要

在化工、动力、石油、制冷等各类行业中,我们时常可以看到各种类型的加热器、凝结器、汽化器、再沸腾器和蒸发器等换热设备,这一现象说明了换热器在工业生产中作为通用的工艺设备具有的地位非常重要。我国的工业日渐发展,需求也日渐增强,所以在对能源开发,利用和节约等方面的要求也要不断提高,那么换热器的技术要求也要随之越来越高,换热器的安全运行,性能结构优化也变得越来越重要。

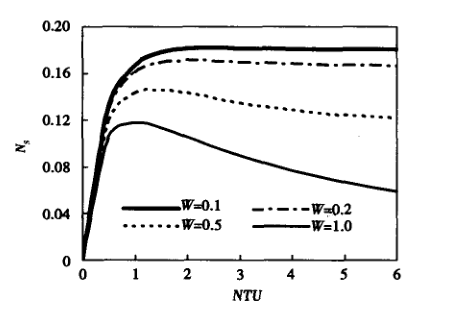

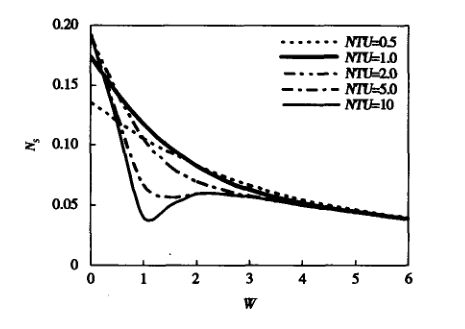

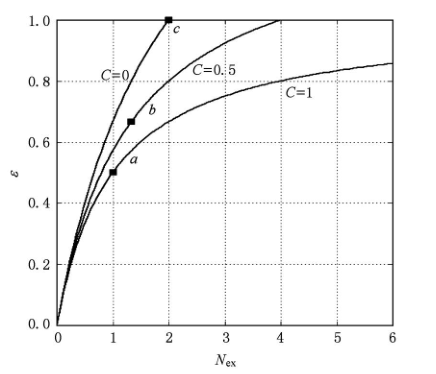

本文先是通过从热量、结构、强度、流动阻力等多个方向和角度来设计出一台lt;1-2gt;型管壳式换热器。此换热器采用逆流布置,传热系数K=301,传热面积为15.9m2。然后分别运用单一性能法、“火积”耗散法、熵产数法、㶲分析法来对本文的换热器进行性能上的分析。通过分析和对比各种性能评价方法得出的数据,对换热器的热力过程分析和完善程度评价,探讨热力特性参数对换热性能的影响。由此我们可以知道有哪些部件,结构能够影响换热器的性能,为进一步优化设计奠定一定的基础。

关键词:管壳式换热器 性能评价方法 传热系数 熵 㶲

Performance Evaluation of Shell and Tube Heat Exchanger

ABSTRACT

The chemical, power, oil, refrigeration and other industries, we always see all kinds of heaters, condensers, carburetors, reboilers and evaporators and other heat transfer equipment, It is shows that the heat exchanger have a important position as a general process equipment in industrial production.China's industrial development, demand is also increasing, so the energy development, utilization and conservation requirements should continue to improve, then the technical requirements of the heat exchanger should also be higher and higher, the heat exchanger safety Operation, performance and structure optimization has become increasingly important.

This paper first through the heat, structure, strength, flow resistance and other directions and angles to design a lt;1-2gt; type shell and tube heat exchanger. The heat exchanger with counter-current layout, heat transfer coefficient K = 301, heat transfer area of 15.9m2. And then use the single parameter method, "volumetric" dissipation method, entropy production method, and energy analysis method to analyze the performance of the heat exchanger in this paper. By analyzing and comparing the data obtained from various performance evaluation methods, the thermal process analysis and the degree of perfection of the heat exchanger were evaluated, and the influence of the thermal characteristics parameters on the heat transfer performance was discussed. So we can know which parts, the structure can affect the performance of heat exchangers, to further optimize the design to lay a certain foundation.

Key words: Shell and tube heat exchanger Performance evaluation Heat transfer coefficient entropy Exergy

目录

摘要..................................................................................................Ⅰ

ABSTRACT..........................................................................................Ⅱ

- 绪论......................................................................................1

1.1研究背景.......................................................................................1

1.2管壳式换热器的介绍与应用.............................................................1

1.3管壳式换热器在国内外的发展现状....................................................2

1.4管壳式换热器的性能分析方法..........................................................4

1.5总结.............................................................................................6

- 性能分析方法

2.1单一性能法....................................................................................7

2.2熵产数法.......................................................................................8

2.3“火积”耗散法.............................................................................11

2.4“㶲”分析法.................................................................................14

第三章 管壳式换热器的设计........................................................16

3.1设计一台换热器所需参数...............................................................16

3.2设计方法和设计步骤.....................................................................16

3.3 工艺计算....................................................................................17

3.3.1物性参数的确定.....................................................................17

3.3.2核算换热器传热面积...............................................................17

3.3.4传热量及平均温差..................................................................17

3.3.5估算传热面积........................................................................18

3.4管壳式换热器结构计算..................................................................20

3.4.1换热器计算及排布方式...............................................................20

3.4.2壳体内径的计算...................................................................22

3.4.3进出口连接管直径的计算.......................................................23

3.4.4折流板................................................................................23

3.5换热系数的计算...........................................................................26

3.5.1管程换热系数.......................................................................26

3.5.2壳程换热系数.......................................................................27

3.6需用换热面积..............................................................................28

3.7流动阻力结算..............................................................................29

3.7.1管程阻力计算.......................................................................30

3.7.2壳程阻力计算.......................................................................30

第四章 基于设计的换热器进行性能分析....................................36

4.1运用单一性能法进行分析.............................................................32

4.2运用熵产数法进行分析................................................................33

4.3运用“火积”耗散法进行分析........................................................35

4.4运用“㶲”分析法进行分析..........................................................36

第五章 结论....................................................................................38

参考文献..........................................................................................39

致谢..................................................................................................41

- 绪论

1.1研究背景

世界各个国家当前都面对着煤油、石油、天然气资源储量逐日减少的场面地步。面对着这样每况愈下的资源环境。世界上有着不少的国家研究和开发新的能源来为国民今后生活的发展做准备。我们国家虽然地大物博,但与此同时我国的人口也高居于世界第一,从人均资源这一方面上看我们国家与世界上其他发达国家相比则就会发现存在着不小的差距。我国的各类的煤矿,水资源大概只占世界平均水平的几分之一,而且我国的能源使用效率也低于例如英美日德这一类发达国家,这说明我国日益发展的生活水平同环境资源的缺乏之间产生了矛盾。为了人民生活水平的发展,我们必须加快对新能源的开发与利用。换热器的研究与发展会促进新能源的开发与利用。其在炼金、食品、医药炼油、化工、建造等各个领域应用都十分广泛,且对于某些工业企业中更是处于无法缺失的地位。随着生产规模的逐日扩大,各种特殊情况以及苛刻的条件接踵而来,对换热器的要求显然会越来越高。因而世界各国虽在不停的大规模生产,仍坚持着热交换器的研究。通过对管壳式换热器的性能评价分析,有助于人们推动管壳式换热器技术的革新,使得没能利用到的能量得到利用,减少能量的浪费,提高换热器的效率以及经济效益。

相关图片展示: