起吊式侧向道路清障车的总体布置与设计毕业论文

2020-02-17 11:10:02

摘 要

随着经济的发展,中国的汽车保有量不断增长,汽车的损坏和违规停车是不可避免的。因此,对清障车的需求也在不断增加。

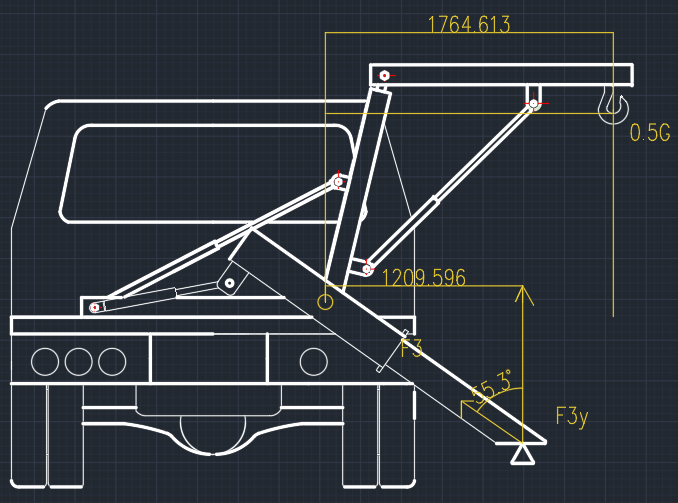

本文首先介绍了清障车的研究背景和发展趋势,然后阐述了侧向道路清障车的基本结构和工作原理。本文在查阅大量相关数据的基础上,深入分析了侧向道路清障车的总体设计方案,合理选择了底盘、提升机构、液压系统及相关配件。通过选择底盘型号来确定车辆的性能参数。利用二维建模软件Auto CAD和三维建模软件CATIA,对汽车的外形和机构进行了设计,并对设计结果进行了校核。

最后,对全文的内容进行了总结,提出了可以进一步研究的部分,并对未来的研究进行了展望。

关键词:清障车;液压装置;机械臂

Abstract

With the development of economy, China's car ownership is constantly growing, and the damage and illegal parking of cars are inevitable. Therefore, the demand for Road block removal truck is also increasing.

This paper first introduces the research background and development trend of the vehicle, and then expounds the basic structure and working principle of the hoisting side road vehicle.On the basis of consulting a large number of relevant data, this paper deeply analyzes the overall design scheme of the lifting lateral road clearance vehicle, and makes a reasonable choice of chassis, lifting mechanism, hydraulic system and relevant accessories.The performance parameters of the vehicle are determined by selecting the chassis model.With the help of Auto CAD, a two-dimensional modeling software, and CATIA, a three-dimensional modeling software, the shape and mechanism of the car were designed, and the design results were checked.

In the end, the paper summarizes the content of the whole paper, proposes the part that can be further studied and looks forward to the future research.

Keywords: Road block removal truck;Hydraulic device;Mechanical arm;check

Catalog

Chapter 1 introduction 1

1.1 classification of road repair vehicles 1

1.2 development status of road repair vehicles at home and abroad 2

1.3 development trend of road repair vehicles in China 3

1.4 main contents of the design 3

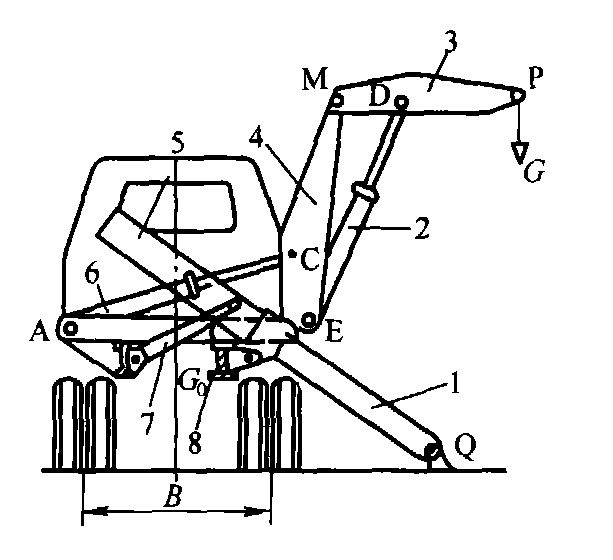

Chapter 2 The working principle and general arrangement of crane type side road trouble car 5

2.1 general layout 5

2.2 operating principle 5

2.3 choice of second type chassis 6

2.4 design of force lifter 7

2.5 chain assembly 8

2.6 summary of this chapter 9

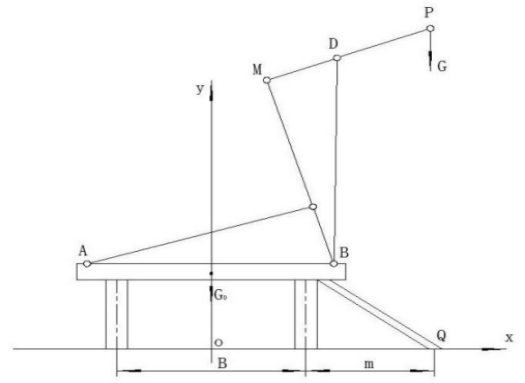

Chapter 3 structural design of side lifting device 10

3.1 structural analysis of side hoisting device 10

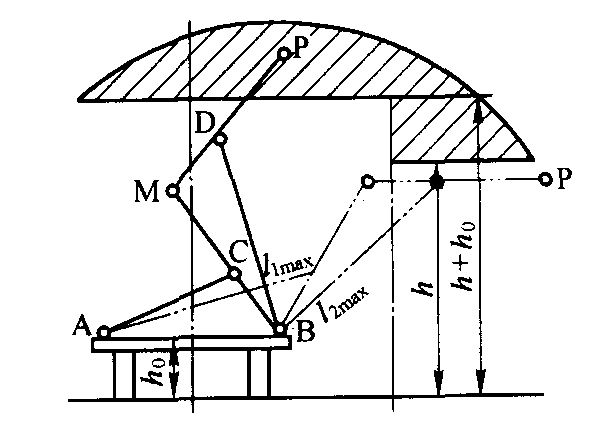

3.2 analysis of working area of side hoisting device 11

3.3 stability calculation 11

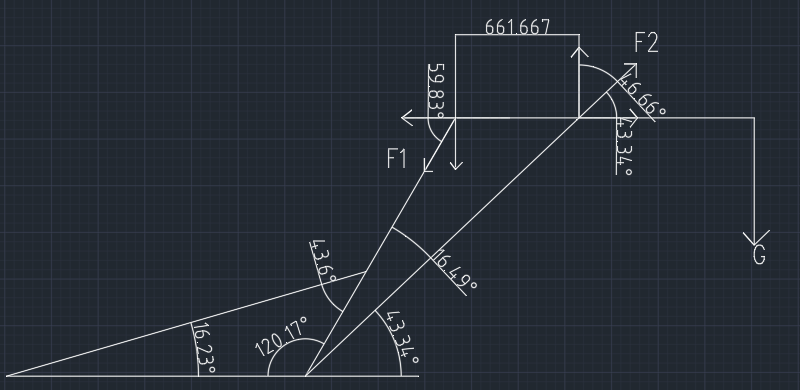

Chapter 4 design and calculation of upper arm and lower arm hydraulic cylinder 13

4.1 cylinder diameter and stroke determination 13

4.2 determination of piston rod diameter d 15

D =0.7 d (4.2) 15

4.3 calculation of hydraulic cylinder wall thickness and outer diameter 16

D -- inner diameter of hydraulic cylinder; 16

4.4 determination of cylinder length 17

4.5 calculation and selection of oil pump 18

4.5.1 calculation of working pressure of oil pump 18

4.5.2 calculation of theoretical flow rate of oil pump 18

4.5.3 calculation of oil pump displacement 19

4.5.4 calculation of oil pump power 19

4.6 summary of this chapter 19

Chapter 5 analysis and calculation of component strength check 20

5.1 upper arm load analysis and strength check 21

5.2 lower arm load analysis and strength check 22

5.3 strength analysis and verification of leg boom 23

Chapter 6. Calculation and analysis of vehicle performance 24

6.1 complete vehicle parameters of road repair vehicles 24

6.2 dynamic performance calculation 25

6.2.1 external characteristics of engine 25

A, b, c -- undetermined coefficients. 25

6.2.2 vehicle driving equation 27

1. Calculation of driving force 27

2. Calculation of rolling resistance 27

6.2.3 calculation of dynamic performance evaluation index 29

2. Maximum climbing slope 30

6.3 chapter summary 31

Chapter 7 Conclusion 32

References 33

Expressing Thanks 35

Chapter 1 Introduction

Road repair vehicle is equipped with road rescue operation equipment a special vehicle, the main parts are chassis, lifting device, hydraulic equipment, electronic control system.It was first used in countries with mature highway traffic development. The task of the fault car is to drag the fault car, accident car or illegal car away from the scene in time to ensure the smooth road.China's economy has developed rapidly over the years, the road traffic infrastructure is becoming more and more perfect, the motor vehicle ownership is also more and more, when the car driving on the highway, inevitably there will be some traffic accident, vehicle failure or on the road the phenomenon of illegal parking in transport, if the car parked on the road because of the failure cause serious traffic congestion, especially on the highway, the speed of the vehicle are soon, traffic is very big.As traffic accidents are unpredictable and damage levels of vehicles vary, traffic management departments need to be able to quickly clean up the accident site, easy to operate, with a variety of functions of the road repair vehicles.

1.1 Classification of road repair vehicles

Road repair vehicles can be classified as light, medium and heavy.Light vehicles are often used for light vehicles, cars, etc.Medium - sized vehicles are often used in medium - sized cars, buses, buses, etc.Heavy duty truck operation objects are heavy trucks and semi - trailer, etc.

According to the type of work, road repair vehicles can be divided into carrier type, lifting type.The delivery mode is to transfer damaged or illegal vehicles to the towing board and remove them from the site;Towed vehicles can lift the front or rear axles of a damaged car and remove them from the scene.In this paper, the lifting device is used to lift (or lift) the two ends of the damaged car off the ground, onto a flat plate and then drag it away from the scene.

According to the structural forms, road obstacle clearance vehicles can be divided into four basic types: boom type obstacle clearance vehicles, portal frame fork type obstacle clearance vehicles, simple fork type obstacle clearance vehicles and back type obstacle clearance vehicles.According to the functional types of the boom, there are rotary boom, folding boom, sliding boom and fixed boom.From the whole vehicle structure to divide, the barrier car has the single function type, the double function type and the multifunction mixture type.

1.2 Development status of road repair vehicles at home and abroad

The fault car was first used in some European and American countries with developed road traffic. In 1950, the United States designed and manufactured the first road fault car.In the first stage of the development of the fault car, this kind of simple road fault car usually USES a homemade chassis to drive the hoist by mechanical transmission, and lifts one end of the fault car and drags it away from the site with a single function.In the second stage of development, the truck began to add hydraulic transmission and control technology.By the 1970s, there were a lot of famous fault car manufacturers, such as the TOKYU in Japan, the CHALLENGER, WRECKER in the United States, and the NRC EMPL in Australia, who started to adopt full hydraulic transmission.At this stage, the technology and development momentum of the fault car is rapid, with more types, larger scale, and various structures and types. In the choice of the fault car chassis, the special chassis for the fault car is developed, and the second type chassis is modified to make it more and more diversified to meet the market demand.The third stage, the structure of the vehicle is diverse, functional, with lifting, lifting, towing, traction, back towing and other functions, and began to intelligent development.

From the 1980s to the 1990s, China began to introduce and imitate foreign road-clearing vehicles.At this point, the abroad has already developed into the third stage, therefore, the road repair car development of China starts relatively late, but the high starting point, at present, our country most car companies using the model introduced combined with independent research and development of production, the manufacturing of road repair car products can basically meet the domestic market needs, but there are some gaps and the world advanced level.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: