承载400kg电动轮设计毕业论文

2020-04-13 11:24:51

承载400KG电动轮设计

学院(系): 国际教育学院

专业班级: 车辆gj1402

学生姓名: 刘岸熙

指导教师: 杨波

学位论文原创性声明

本人郑重声明:所呈交的论文是本人在导师的指导下独立进行研究所取得的研究成果。除了文中特别加以标注引用的内容外,本论文不包括任何其他个人或集体已经发表或撰写的成果作品。本人完全意识到本声明的法律后果由本人承担。

作者签名:

年 月 日

学位论文版权使用授权书

本学位论文作者完全了解学校有关保障、使用学位论文的规定,同意学校保留并向有关学位论文管理部门或机构送交论文的复印件和电子版,允许论文被查阅和借阅。本人授权省级优秀学士论文评选机构将本学位论文的全部或部分内容编入有关数据进行检索,可以采用影印、缩印或扫描等复制手段保存和汇编本学位论文。

本学位论文属于1、保密囗,在 年解密后适用本授权书

2、不保密囗 。

(请在以上相应方框内打“√”)

(宋体小四号)

作者签名: 年 月 日

导师签名: 年 月 日

Abstract

The design consists of three parts: design goal analysis, overall plan design, parameter calculation and structural design. First analyze the design goals and then determine the overall design plan. Finally, the most important structural design is carried out, and the design parameters of the components that need to be structurally designed are calculated and verified: the calculation and verification of the gears in the planetary gear mechanism, the calculation and verification of the shaft, and the calculation of the braking torque of the brake disc, hub checking. The relevant calculations and checks are made on the motors and standard parts that need to be selected: calculation of motor performance parameters and verification of bearings. And all the parts of the three-dimensional modeling and two-dimensional drawing.

Key Words:electric vehicle; hub motor;planetary gear mechanism;bearings;solar wheel shaft; breaking

Catalogue

Chapter1 Introduction 1

1.1Electric wheel technology overview 1

1.2Domestic and foreign research status 2

1.2.1Foreign research status 2

1.2.2Domestic research status 3

1.3Thesis design content 4

Chapter2 Electric wheel design target analysis 4

2.1 Determination of electric wheel foundational vehicle 4

2.2 Determination of electric wheel vehicle driving type 5

2.3 Design target 5

Chapter3 Plan of electric wheel design 6

3.1 Hub motor structure and connection 6

3.1.1 Determination of hub motor structure 6

3.1.2 Determination of hub motor connection 7

3.2 Determination of bearing structure 7

3.3 Structure and connection of transmission mechanism 7

3.3.1 Determination of planetary gear mechanism type 7

3.3.2 Transmission mechanism diagram 7

3.3.3 Determination of planetary gear mechanism connection type 8

3.4 Structure and connection of brake 8

3.4.1 Determination of brake disc structure 8

3.4.2 Determination of brake disc connection 9

3.5 Determination of the general design plan of electric wheel 9

Chaper4 Structure design and calculation of electric wheel 9

4.1 Calculation of performance parameters of hub motor 9

4.1.1 Power balance equation of electric wheel vehicle 9

4.1.2 Performance requirement of hub motor 11

4.2 Design and calculation of wheel hub bearing 14

4.3 Design and calculation of shaft 15

4.3.1 Structure design of shaft 15

4.3.1.1 Design and checking of rotor shaft 15

4.3.1.2 Design and check of solar wheel shaft 16

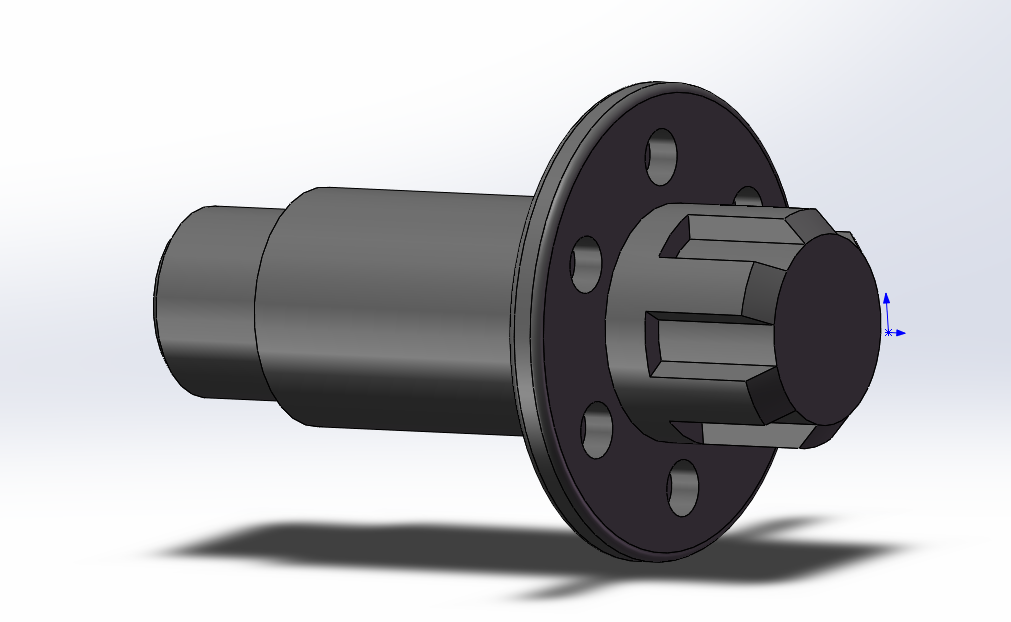

4.3.2 Three dimensional model of shafts 17

4.4 Design and calculation of transmission mechanism 18

4.4.1 Calculation of tooth distribution of planetary gear transmission 18

4.4.2 Design and calculation of solar gear 19

4.4.2.1 Determination of gear material 19

4.4.2.2 Calculation of the size parameters of solar gear 20

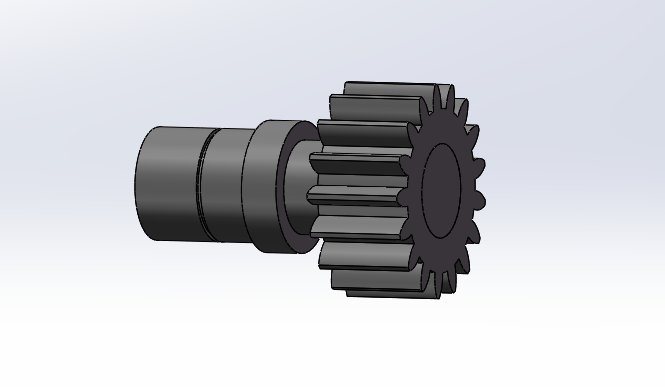

4.4.2.3 Three dimensional model of solar gear 23

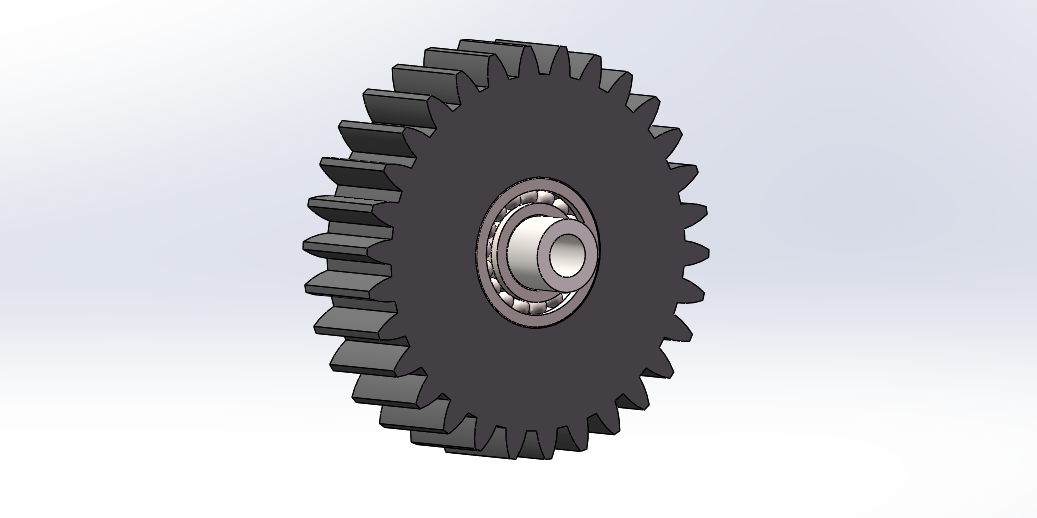

4.4.3 Design and calculation of planetary gear 23

4.4.3.1 Calculation of the size parameters of planetary gear 23

4.4.3.2 Three dimensional model of planetary gear 24

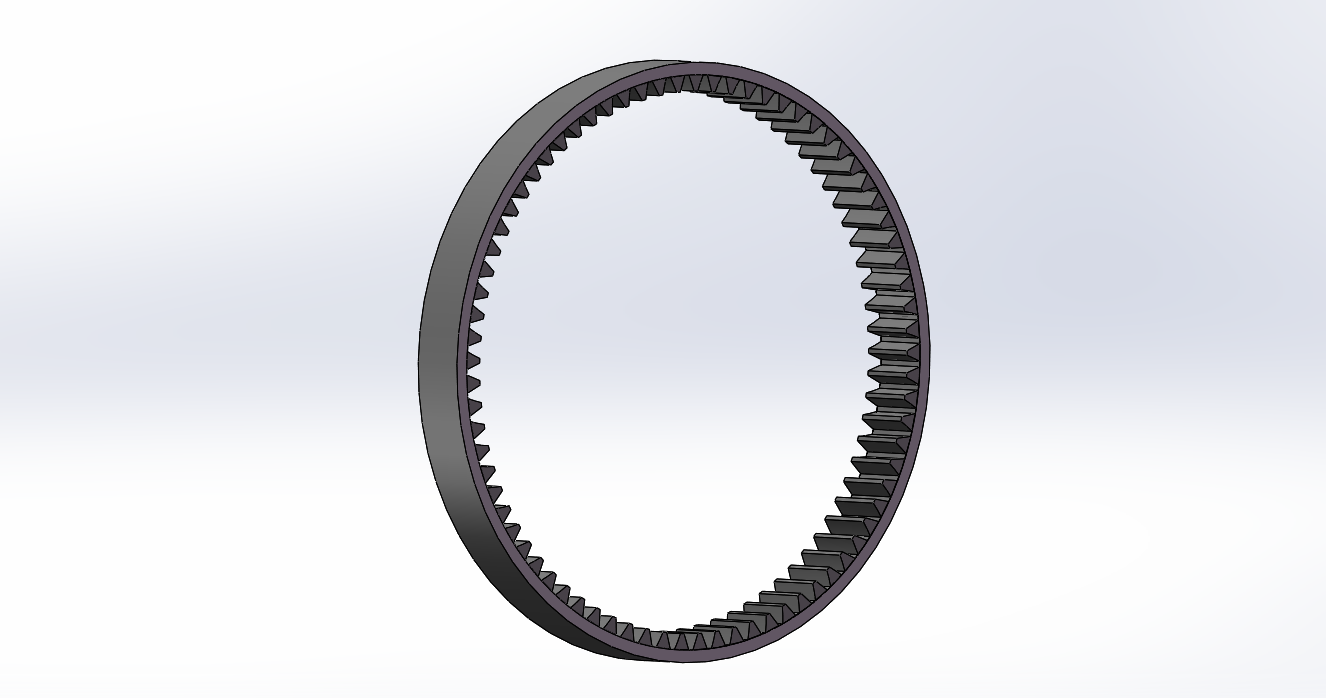

4.4.4 Design and calculation of internal gear 24

4.4.4.1 Calculation of the size parameters of internal gear 24

4.4.4.2 Three dimensional model of internal gear 25

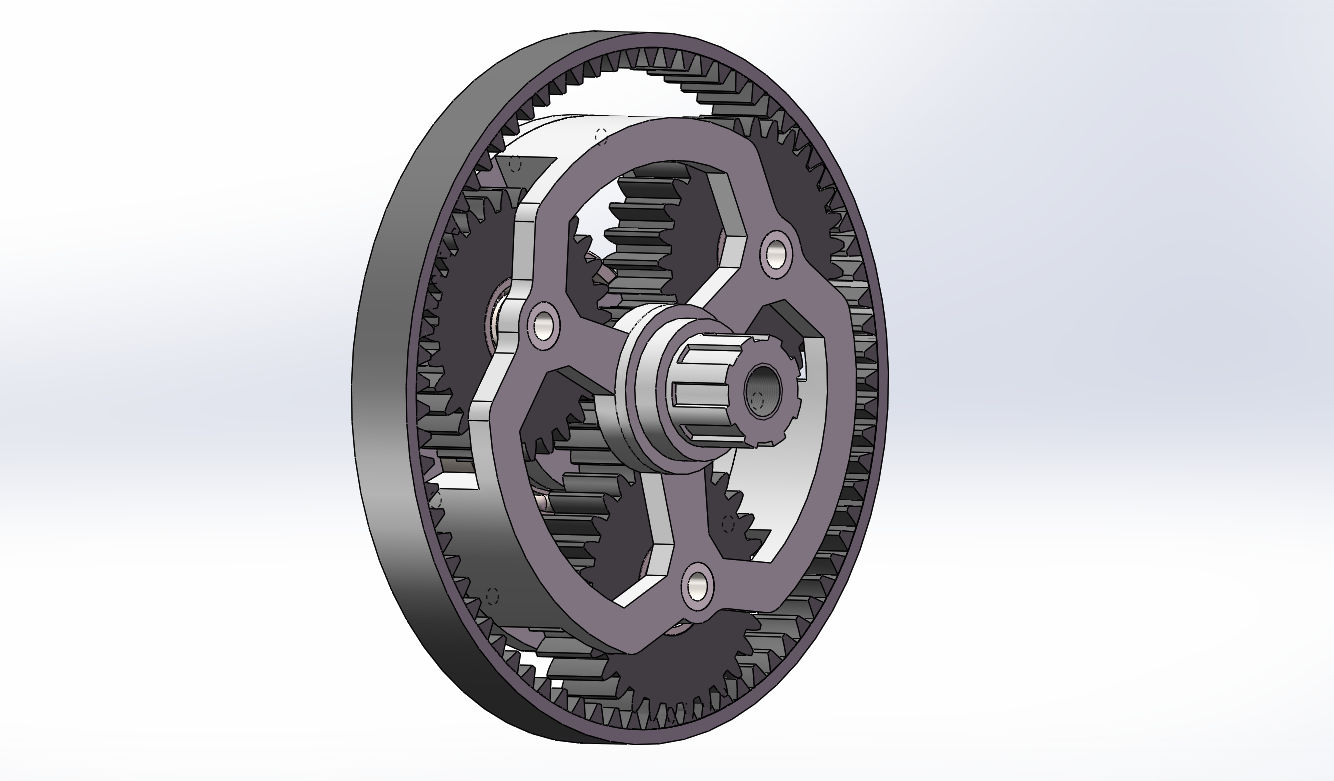

4.4.5 Planetary gear mechanism assembly 26

4.5 Design and calculation of brake disc 26

4.5.1 Determination of the maximum braking torque 26

4.5.2 Three dimensional model of brake disc 28

Chaper5 Summary and prospect 28

Reference 29

Thanks 32

Chapter1 Introduction

1.1Electric wheel technology overview

With the rapid development of the electrification and intelligentization of the automotive industry, the world’s major automotive manufacturers have regard electric vehicles as the main development trend in the future. The electric drive system is the core technology of the electric vehicle powertrain system. Electric drive systems currently fall into three main categories: concentrated motor drives, wheel-side motor drives, and electric wheel drives. Concentrated motor drive is used to drive an engine in an internal-combustion engine to an electric motor. A wheel-side motor drive means that a motor and a constant speed ratio reducer are integrated into a frame, and power is output from the output shaft of the speed reducer. The section is transmitted to the wheel axles to drive the wheels. The electric wheel drive, also known as the hub motor drive, integrates the hub motor, transmission mechanism, brake and other components in the rim, and the power is directly driven by the hub motor through the transmission mechanism. Is a separate drive unit. The first two drive technologies have now been widely applied to mass-produced pure electric vehicles and hybrid vehicles, and electric wheel drive technology has not been widely applied to mass-produced pure electric cars because of high technical and cost requirements. . However, because electric wheel drive still has many advantages compared to the former two technologies, electric wheel technology is a very promising research direction.

Compared with other driving methods, electric wheels driven by electric wheels have many advantages:

(1) The transmission components such as clutch, transmission, transmission shaft and differential are eliminated, the transmission system is simplified, the transmission efficiency is improved, and the driving speed is reduced. Noise.

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: