纯电动汽车制动系统设计毕业论文

2020-04-10 16:16:50

纯电动汽车制动系统设计

学院(系): 国际教育学院

专业班级: 车辆GJ403班

学生姓名: 王若曦

指导教师: 李其仲

学位论文原创性声明

本人郑重声明:所呈交的论文是本人在导师的指导下独立进行研究所取得的研究成果。除了文中特别加以标注引用的内容外,本论文不包括任何其他个人或集体已经发表或撰写的成果作品。本人完全意识到本声明的法律后果由本人承担。

作者签名:

年 月 日

学位论文版权使用授权书

本学位论文作者完全了解学校有关保障、使用学位论文的规定,同意学校保留并向有关学位论文管理部门或机构送交论文的复印件和电子版,允许论文被查阅和借阅。本人授权省级优秀学士论文评选机构将本学位论文的全部或部分内容编入有关数据进行检索,可以采用影印、缩印或扫描等复制手段保存和汇编本学位论文。

本学位论文属于 1、保密囗,在 年解密后适用本授权书

2、不保密囗 。

(请在以上相应方框内打“√”)

作者签名: 年 月 日

导师签名: 年 月 日

Abstract

The car was born because of its speed, but the car often encounters complex and variable road conditions during driving, such as entering curves, uneven roads, two-car intersections, and sudden obstacles. In order to ensure the safety of driving, the car is required to Decelerate or even stop in the shortest distance. As one of the four major systems of the automobile chassis, the braking system can effectively control the speed of the vehicle and is an active guarantee for the safety of the vehicle.[1]

The brake is an important part of the braking system. This paper mainly introduces the brake design of the passenger car. Starting from the comparison of the structure and performance of disc type and drum brakes, disc brakes have become the mainstream of current brake systems due to the increasing performance and driving speed of vehicles, in order to increase the braking performance of vehicles at high speeds. Since the disc brake disc is exposed to air, the disc brake has excellent heat dissipation. When the vehicle is in emergency braking at a high speed, the braking performance is less likely to decline, and the vehicle can obtain the best braking effect to improve the driving safety of the vehicle. In addition, due to the rapid response of disc brakes, high-frequency braking actions can be completed. Therefore, modern passenger cars mostly use braking schemes that are used with ABS systems, ESP systems, and disc brakes to meet the requirements of rapid braking. [2]

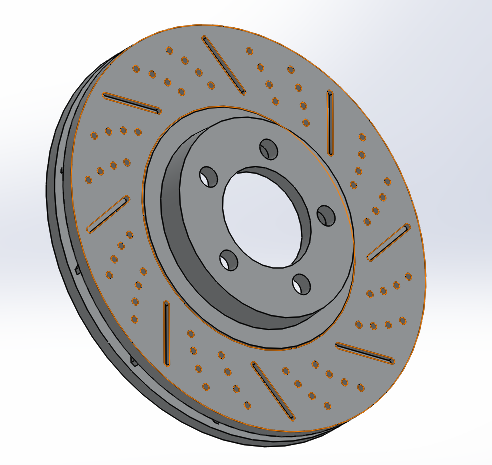

Taking into account the above advantages of disc brakes, and the overall performance of the referenced models is better, which belongs to mid-to-high grade passenger vehicles. Therefore, this design has adopted floating disc brakes for front and rear wheels, ventilated discs for front wheels and discs for rear wheels. brake.[3]

After the basic form of the brake is selected, the following design of the brake is developed in this paper. 1. Parameters of braking system: including the selection and calculation of braking force distribution coefficient, synchronous adhesion coefficient, braking strength, adhesion coefficient utilization rate and maximum braking torque; 2. Brakes and their components: brake discs, system The size calculation and material selection of the brake parts such as movable caliper body and friction pad, etc. 3. Parking brake: The rear parking brake is selected for this design, and the parking brake is installed on the rear wheel brake. The mechanical structure; Fourth, the brake drive mechanism: brake wheel cylinder, brake master cylinder, and pedal stroke design calculations.

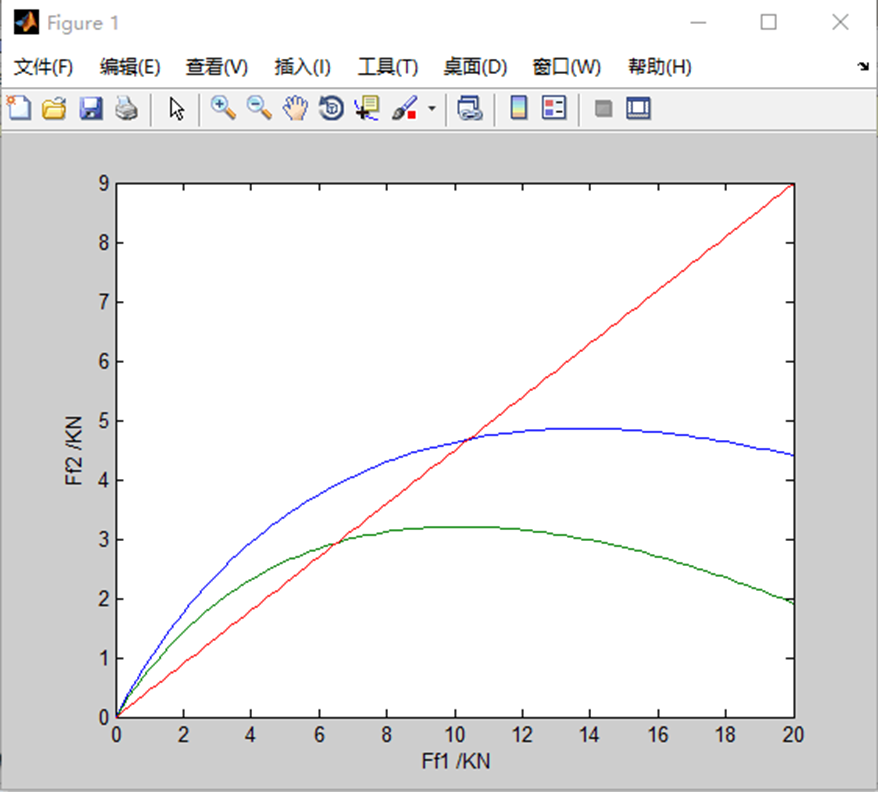

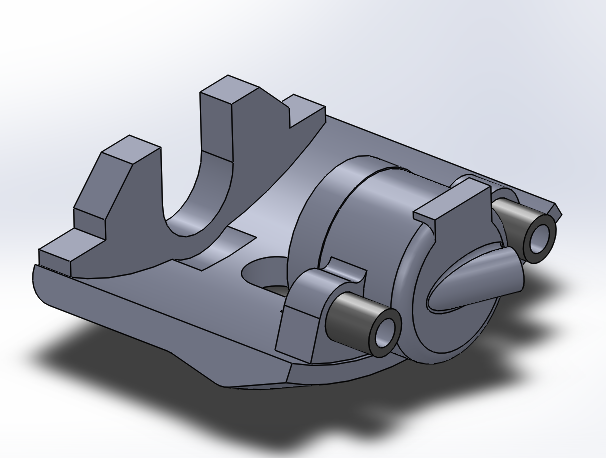

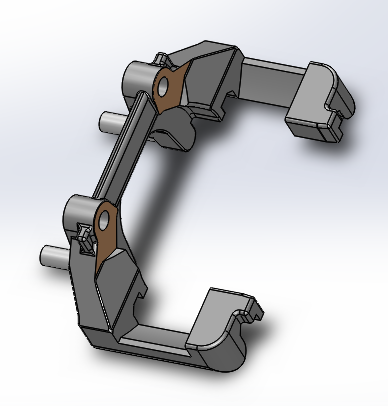

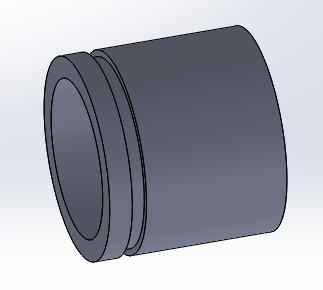

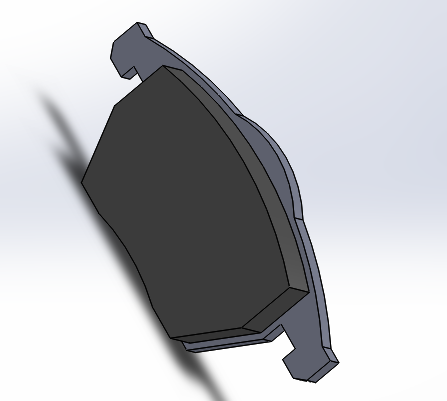

After the above design is completed, the braking deceleration and braking distance of the designed brake are calculated, and the front and rear axle braking force distribution curves are drawn using MATLAB programming. After the above requirements are met, the rationality of the brake design is verified. . Finally, the three-dimensional model of the brake caliper body, brake disc, piston, and friction pad of the vehicle brake was designed and designed using solid works.[4]

Keywords: EV;braking system;disc brake;SOLID WORKS;MATLAB

Contents

Abstract III

1.Introduction 1

1.1 Basic concept of braking system 1

1.1.1 The composition of the braking system 1

1.1.2 Type of braking system 1

1.2 Research status of braking system 2

1.3 Main content of the project 4

1.4 Project research scheme 7

2.The choice of brake form 8

2.1 Introduction of drum brakes 8

2.2 Introduction of disc brakes 9

2.3 Selection of brake structures 10

3.Main parameters and selection of brake 11

3.1 Determination of main parameters of disc brake 11

3.1.1 Brake disc diameter D 11

3.1.2 Thickness of brake disc h 11

3.1.3 Inside and outside radius of friction liner 12

3.1.4 Working area of brake liner A 12

4.Structural design of main parts of disc brake 13

4.1 brake disc 13

4.2 Brake caliper 13

4.3 Brake slipper 14

4.4 Friction material 15

5. Design and calculation of main parameters of brake 16

5.1 Determination of synchronous adhesion coefficient 18

5.2 Normal reaction of ground to front and rear wheels 19

5.3 Determination of the distribution coefficient β of braking force 20

5.4 Determination of braking moment for front and rear brakes 20

5.5 Braking torque required for emergency brake and parking brake 21

5.5.1 Emergency brake 21

5.5.2 Parking brake 21

5.5.3 Calculation of wear characteristics of linings 22

6.Structural form selection and design calculation of brake drive mechanism 24

6.1 Choice of structure form of braking drive mechanism 24

6.2 Multi-loop system for braking pipeline 26

6.3 Design and calculation of hydraulic braking drive mechanism 28

6.3.1 Determination of the diameter of the brake wheel cylinder 29

6.3.2 Determination of the diameter of the main brake cylinder 29

6.3.3 Braking pedal force and pedal stroke 30

6.3.4 Design and calculation of vacuum booster 31

7.Brake performance analysis 32

7.1 Braking performance Evaluation Index 32

7.2 braking efficiency 32

7.2.1 braking deceleration 32

7.2.2 braking distance S 33

7.3 The constant braking performance 33

7.4 The direction stability of the vehicle during braking 33

7.5 Analysis of braking force distribution curve 34

Conclusion 36

Reference 37

Acknowledgements 38

Appendix A Brake 3D modeling 39

Appendix B Exploded view 45

Appendix C MATLAB programming 46

Appendix D EXCEL calculation 47

1.Introduction

1.1 Basic concept of braking system

Decelerating or even stopping the car in motion, keeping the speed of the downhill car stable, and keeping the stopped car from moving, these actions are collectively referred to as car braking.

The braking effect on the car is the external force acting on the car in the opposite direction of the car. The rolling resistance, uphill resistance, and air resistance that act on the moving car can all act as a brake on the car, but the size of the external force is random and uncontrollable. Therefore, a series of special devices must be installed on the car so that the driver can apply certain forces to the car (mainly the road wheels) in accordance with the conditions of the road and traffic, etc. to apply certain force to the car. A certain degree of forced braking. This controllable external force to brake the car is collectively referred to as braking force. Such a series of specialized devices is called braking system.[2]

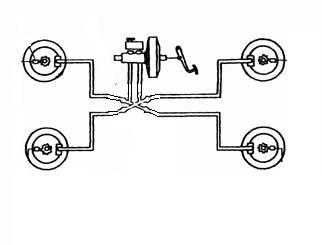

1.1.1 The composition of the braking system

Any braking system has the following four basic components:[4][5]

1) Energizing devices - Including various components that supply, regulate the energy required for braking, and improve the state of the energy transfer medium. Among them, the part that generates braking energy is called braking energy.

2) Control device - Including various components that produce braking action and control braking effect.

3) Transmission - Includes various components that transmit braking energy to the brake.

4) Brake - A component that generates a force that impedes the motion or movement tendency of the vehicle, which also includes a retarding device in the auxiliary brake system.

The complete brake system also has brake force adjustment devices and alarm devices, pressure protection devices and other additional devices.

1.1.2 Type of braking system

Classified according to the function of the braking system:[4]

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: