电动汽车ABS控制系统的设计毕业论文

2020-02-17 10:55:51

摘 要

汽车防抱死制动系统(ABS)在汽车制动时,可以自动调节车轮制动力,防止车轮抱死以取得最佳制动效果,是一项很重要的汽车主动安全装置,一辆汽车的ABS是否能有效的工作直接关系到驾驶人员行车时的生命安全。由于我国对 ABS 研究较晚,我们所拥有的自主知识产权的产品不多。因此,ABS 技术的研究发展对我国汽车产业具有现实意义,它已成为中国汽车产业的重要课题。

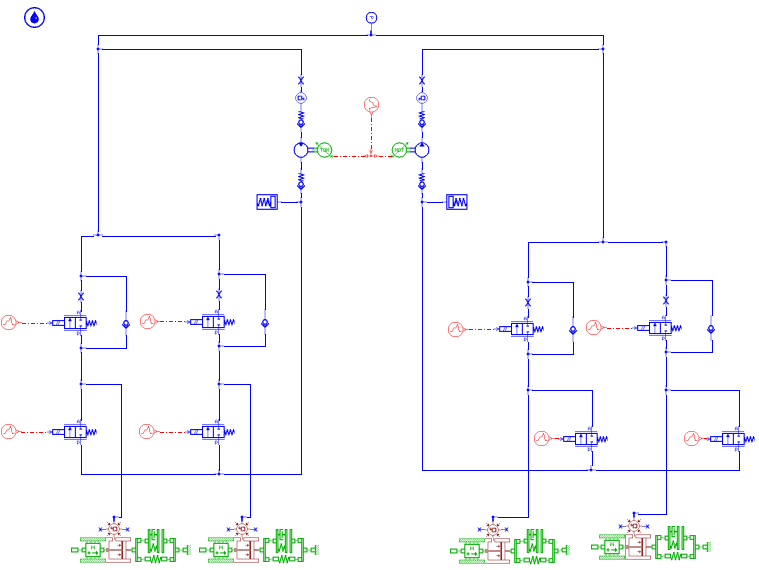

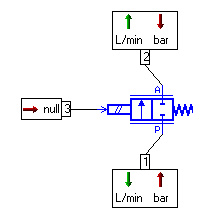

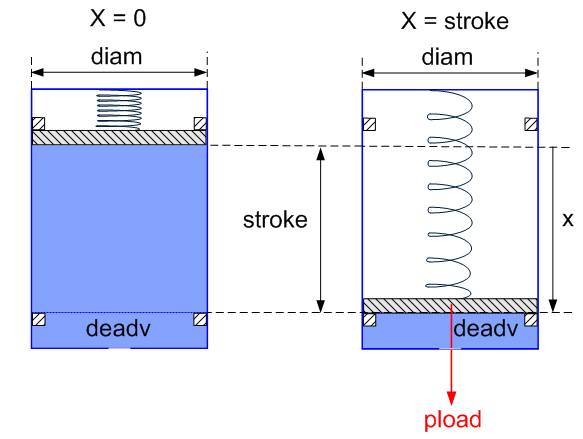

本文首先在查阅了很多相关资料的基础上,介绍了 ABS 的工作原理、构成和发展趋势。然后,在AMESim中建立了液压控制的模型,包括液压调节器的模型,主缸模型和轮缸模型,并且进行了制动过程中增压,保压,减压的仿真分析。然后在Matlab/Simulink 中建立ABS的控制系统,通过对实际的滑移率和要控制的理想滑移率的对比,选择增压,减压或者保压。 然后在预设初始速度的情况下进行仿真,得到滑移率变化曲线,轮速和车速的变化曲线以及制动距离等结果。仿真结果表明,该ABS可以使滑移率维持在理想滑移率附近,防止车轮抱死。

关键词: ABS;滑移率;逻辑控制;联合仿真

Abstract

Anti-lock Braking System (ABS) is an important active safety device for automobiles, which can automatically adjust the wheel braking force and prevent the wheel from locking in order to achieve the best braking effect. Whether an ABS can work effectively or not is directly related to the driver's safety in driving. Because of the late research on ABS in China, we have few products with independent intellectual property rights. Therefore, the research and development of ABS technology has practical significance for China's automobile industry, and it has become an important topic for China's automobile industry.

Firstly, on the basis of consulting a lot of relevant information, this paper introduces the working principle, composition and development trend of ABS. Then, the hydraulic control model is established in AMESim, including hydraulic regulator model, main cylinder model and wheel cylinder model, and the simulation analysis of boosting, holding and decompression during braking process is carried out. Then the control system of ABS is established in MATLAB/Simulink. By comparing the actual slip rate with the ideal slip rate to be controlled, the boosting, decompression or holding pressure are selected. Then the slip rate curve, wheel speed and vehicle speed curve and braking distance are obtained by simulation under the condition of preset initial speed. The simulation results show that the ABS can keep the slip rate near the ideal slip rate and prevent the wheel from locking.

Key Words:ABS;Slip ; Logic Control; Joint Simulation

catalogue

Chapter 1 Introduction 1

1.1 Purpose and significance 1

1.2 Overview of Research at Home and Abroad 2

1.2.1 Overview of ABS System Development Abroad 2

1.2.2 Development of ABS System in China 2

1.2.3 Characteristics of Automotive ABS System 3

1.3 Basic contents, objectives, technical schemes and measures to be adopted in the design 4

1.3.1 Design content 4

1.3.2 Design goal 5

1.3.3 Proposed scheme 5

Chapter 2 Working Principle of Automotive ABS Control System 6

2.1 Component Composition and Function of Automotive ABS Control System 6

2.1.1 Wheel speed sensor 7

2.1.2 Electronic Controller 7

2.1.3 Hydraulic regulator 7

2.2 Working Principle of Automotive ABS System 8

2.3 Analysis of Braking Process of Automobile 8

2.4 Summary 11

Chapter 3 Modeling of Hydraulic Regulator Based on AMESim 13

3.1 AMESim Software introduction 13

3.1.1 AMESim software function 13

3.1.2 AMESim Software Characteristics 14

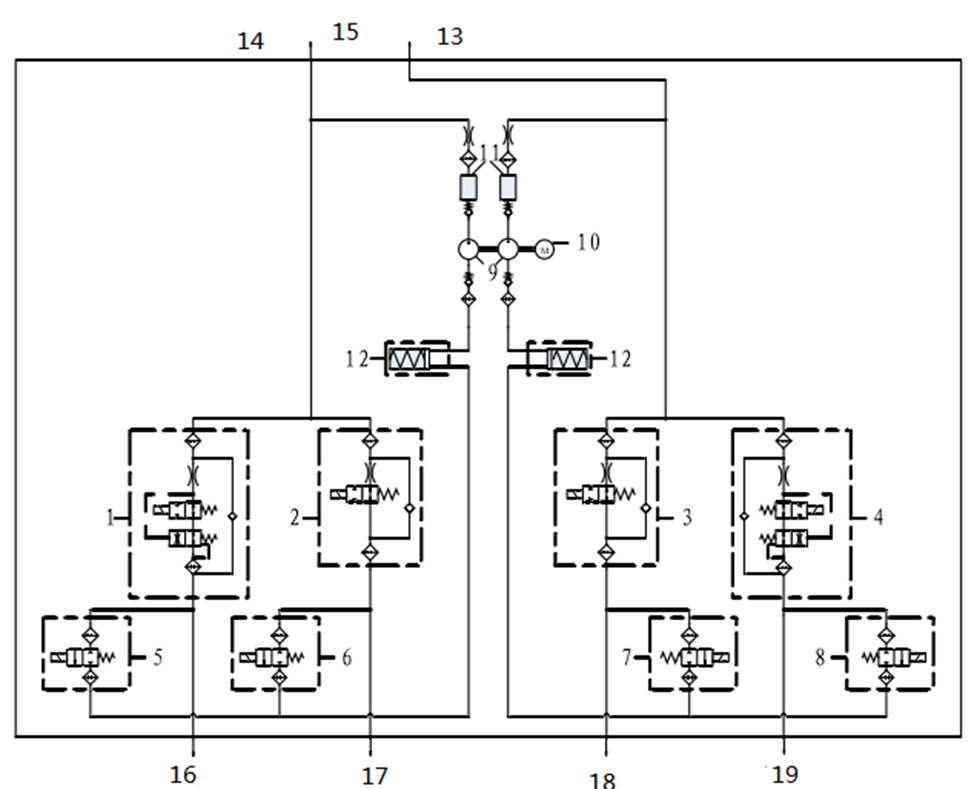

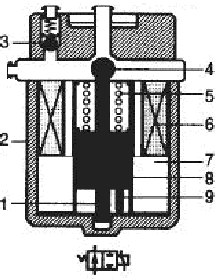

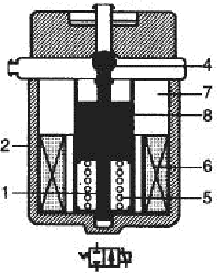

3.2 Working Principle and Structure of Hydraulic Regulator 16

3.2.1 Working Principle of Hydraulic Regulator 16

3.2.2 Structure of Hydraulic Regulator 18

3.3 Establishment of Hydraulic Regulator Model Based on AMESim 21

3.3.1 Setting up the Scheme of Hydraulic Regulator 21

3.3.2 Selection of Hydraulic Regulator Component Submodel 22

3.3.3 Setting Model Parameters of Hydraulic Regulator 24

3.4 Model simulation of hydraulic regulator 25

Chapter 4 Modeling and Co-simulation of Automotive ABS System Based on Simlink 28

4.1 Automotive ABS simulation environment 28

4.1.1 Introduction of simulation environment 28

4.1.2 Interface settings of simulation software 28

4.1.3 Interface configuration 30

4.2 Model establishment in simulink 33

4.2.1 Introduction of simulation software Simulink 33

4.2.2 Vehicle Dynamics Model 33

4.3 Joint simulation 37

Chapter 5 Conclusion 40

Reference 41

Acknowledgement 42

Chapter 1 Introduction

1.1 Purpose and significance

With the development of China's automotive industry, it is necessary to carry out independent research and development of key automotive components. Safety in the process of automobile braking has also become the focus of attention. Anti-lock braking system of automobile is related to the safety of automobile braking. Recently, many domestic automobile companies have begun to develop automobile independently. In order to stand out in the commercial competition, automobiles with independent intellectual property rights must be changed from a big automobile country to a powerful automobile country. Autonomous research and development of key automotive components is required. Safety in the process of automobile braking has become the focus of attention. ABS is one of the key components of automobile. The improvement of automobile power performance and the extension of expressway have put forward higher and higher requirements for automobile safety. Many countries have promulgated strict automobile safety regulations for this purpose. The direction stability and steering control ability of automobile in braking process have become the focus of attention. Therefore, it is an important measure to reduce traffic accidents and promote the development of automobile industry to explore various high-performance braking systems and improve the performance of braking systems. ABS can automatically and frequently adjust the braking system pressure during the braking process, so as to adjust the braking force, keep the wheel slip rate near the ideal aliasing rate, not only prevent the wheel from locking, but also make full use of the adhesion between the wheel and the road, shorten the braking instant departure, improve the direction stability and steering operation ability in the braking process of automobiles. It's the day of the best braking effect. One of the key points of ABS control is to control the slip rate in the braking process, so as to improve the utilization ratio of road adhesion coefficient, shorten the braking instant departure and improve the braking stability. However, the relationship between slip rate and road adhesion coefficient is affected by many factors, such as vehicle structure parameters, vehicle speed, tire inflation pressure, tire vertical load, road condition and so on.

1.2 Overview of Research at Home and Abroad

1.2.1 Overview of ABS System Development Abroad

The theory of anti-lock braking was first put forward by the British in 1928. The braking system based on the theory of anti-lock braking was first applied to trains and airplanes. The earliest official record of the anti-lock braking system was a patent 382241 issued in 1932 in the United Kingdom. ABS began to be used on automobiles in the mid-1950s by Ford Motor Company. In 1954, Ford Motor Company assembled ABS device of Air France on Lincoln. The control part of ABS device is mechanical, complex in structure and relatively single in function. Only in specific vehicles and working conditions, anti-lock braking control is effective, so the braking effect is not ideal. Because of the poor reliability, low control accuracy and high price of ABS devices, it is difficult to popularize and apply ABS technology in automobiles. Until the late 1970s, the rapid development of electronic technology provided reliable technical support for the application of ABS technology in automobiles. Electronic control is adopted in ABS control part. Its reaction speed, control accuracy and reliability are significantly improved, and the braking effect is also significantly improved. At the same time, its volume is gradually smaller, its quality is gradually reduced, its control and diagnosis function is constantly enhanced, and its price is gradually reduced. During this period, many companies have developed a variety of ABS devices. Since the 1990s, ABS technology has been developing and maturing, and its control precision and function have been improved. ABS technology has been widely used in developed countries.

1.2.2 Development of ABS System in China

Domestic research on ABS began in the early 1980s. The research units include Dongfeng Automobile Company, Chongqing Highway Institute of the Ministry of Communications, Chongqing Hongan ABS Co., Ltd., Xingping 514 Factory of Shaanxi Province and Xi'an Jiaotong University. Dongfeng Automobile Company began to study ABS in the early 1980s. The company analyzed, tested, improved and digested the ABS products of Wabco Company. The ABS of WABCO was installed on EQ-145 vehicle and tested on various roads. Since 1998, our own Audi, Santana and Fukang vehicles have been equipped with ABS system. Since 2003, ABS has become the benchmark equipment for small passenger cars. In terms of theoretical research, the State Key Laboratory of Automobile Dynamic Simulation, represented by Academician Guo Konghui of Jilin University, has made a lot of achievements in tire model building: Professor Song Jian of the State Key Laboratory of Automobile Safety and Energy Conservation of Tsinghua University has made many studies on ABS; in terms of air pressure ABS, domestic enterprises include Dongfeng Electronics Technology Co., Ltd., Ltd. Chongqing Juneng and Guangdong Kemi have formed a certain scale of production: hydraulic ABS can not be produced independently by domestic enterprises for the time being because of its difficult technology and tight technology blockade abroad, but it is also doing independent research and development in hydraulic ABS, trying to break through the technical barriers of foreign multinational companies, and has made some new progress and breakthroughs.

1.2.3 Characteristics of Automotive ABS System

The main characteristics of automobile ABS system are as follows:

(1)Stability during braking

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: