基于Procast的多连体铸件凝固过程模拟及缺陷预测毕业论文

2020-04-15 18:02:34

摘 要

IAbstract II

第一章绪论 3

1.1课题的背景以及意义 3

1.2本课题的主要研究内容 6

1.3本章小结 7

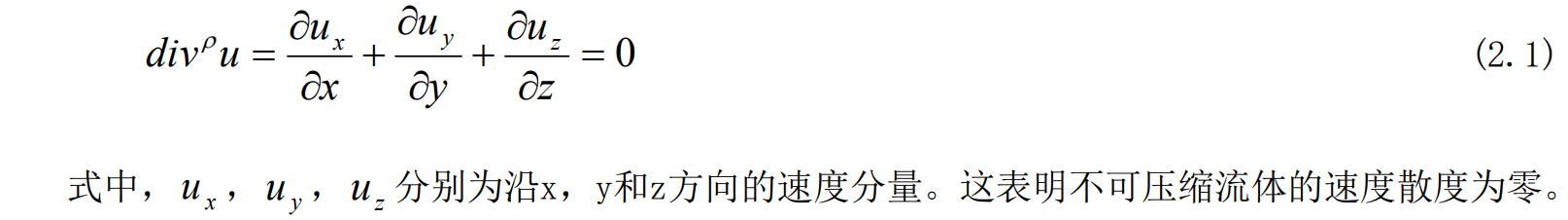

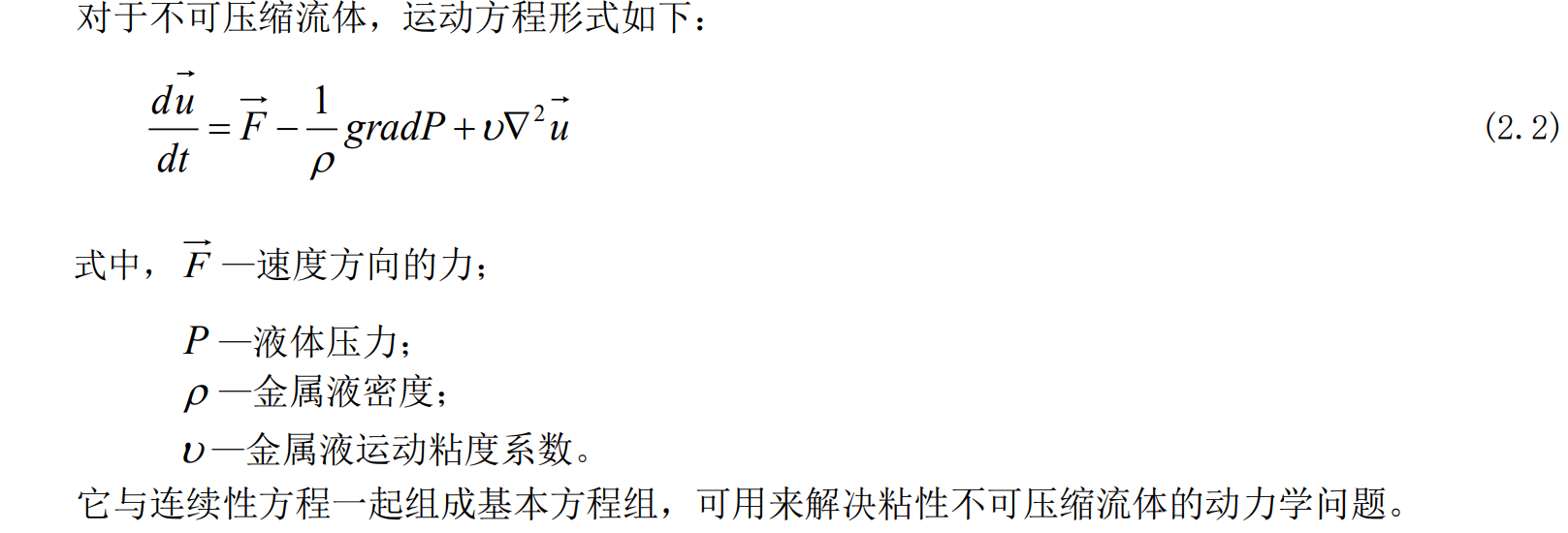

第二章 铸造成型数值模拟基本原理 8

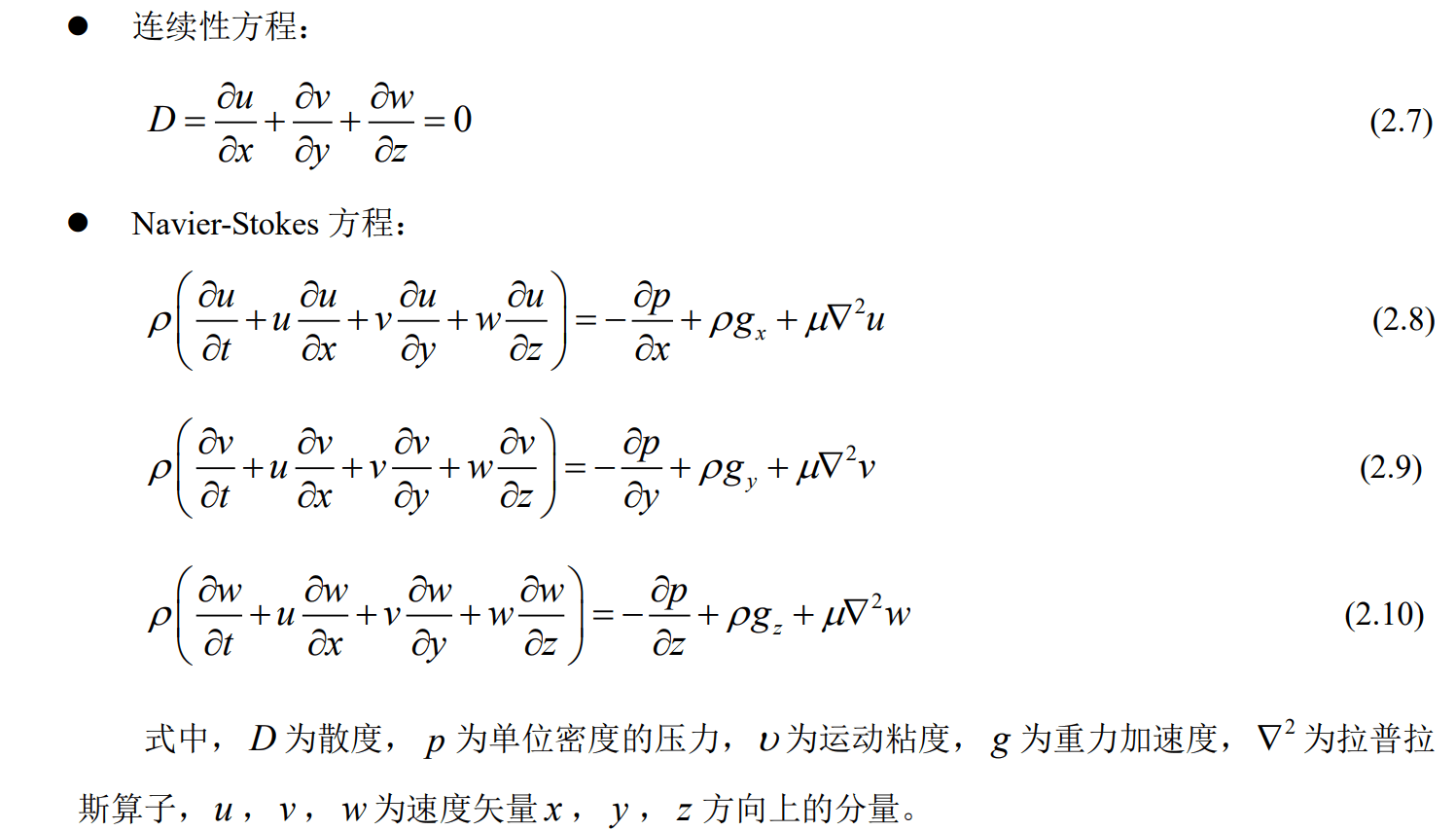

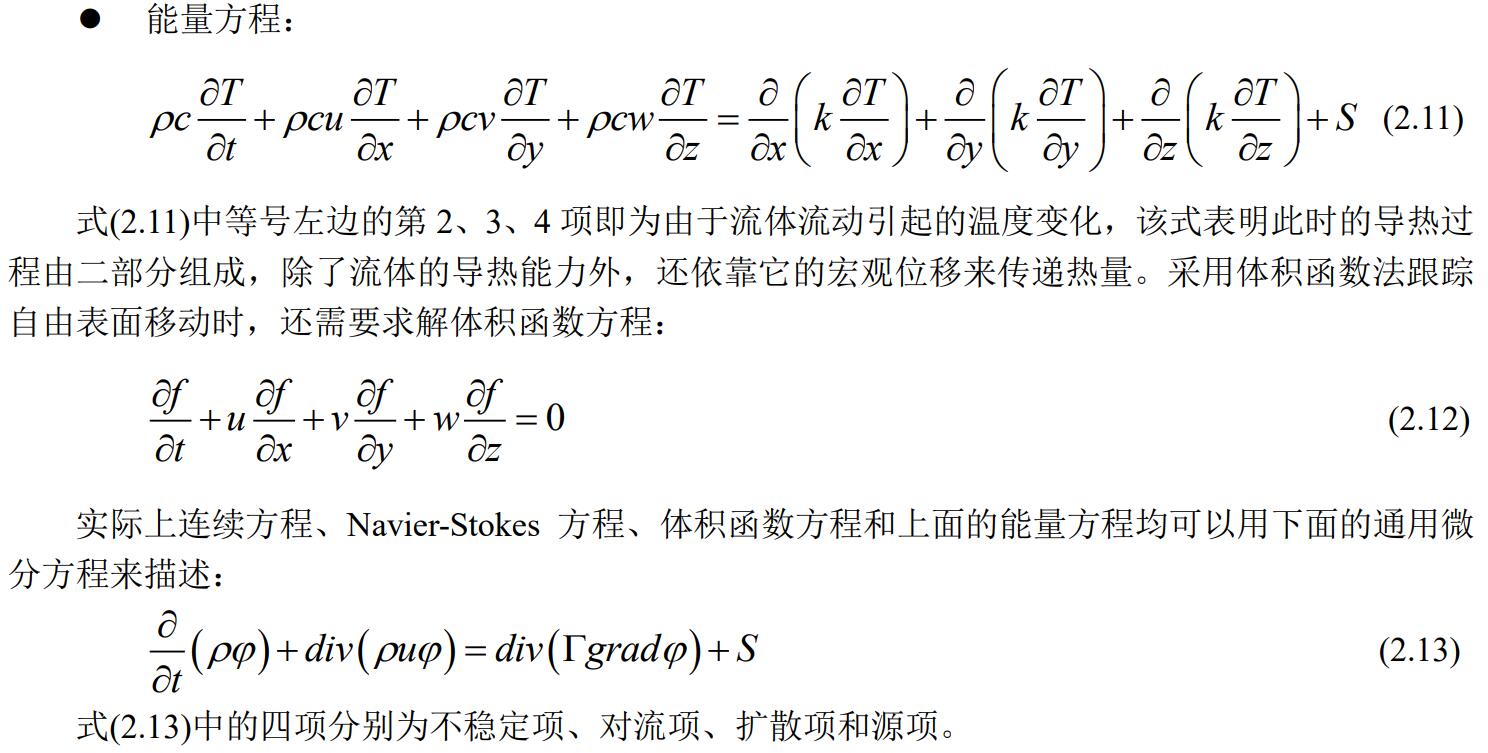

2.1充型过程中的数学模型 8

2.2充型过程中常用的数值模拟方法 10

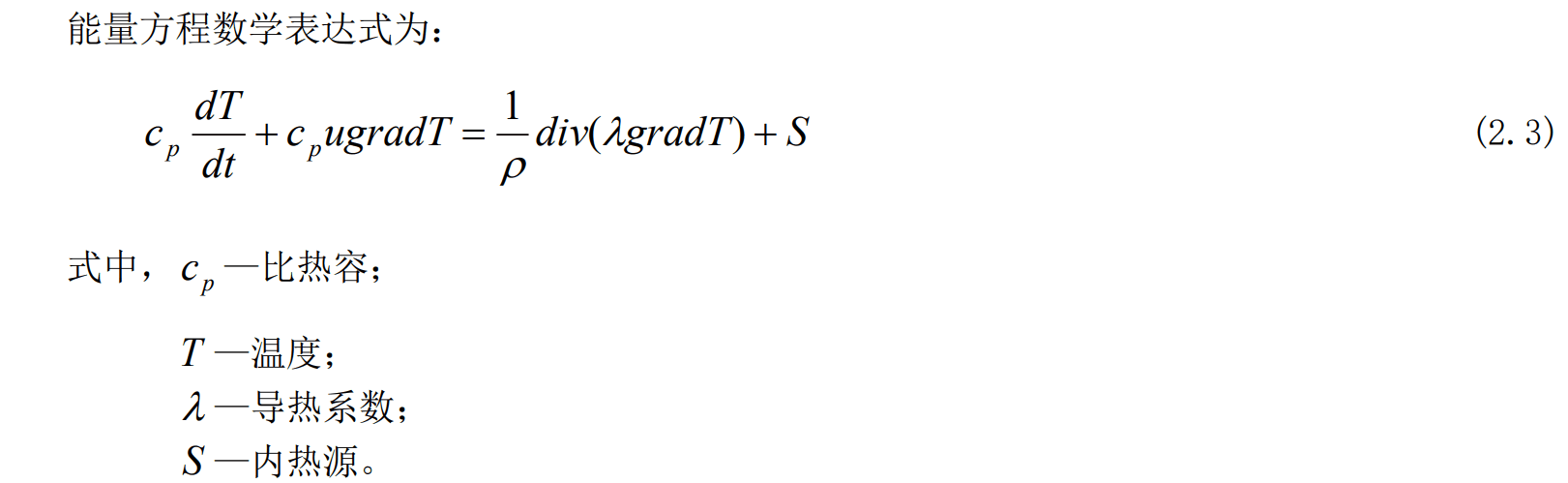

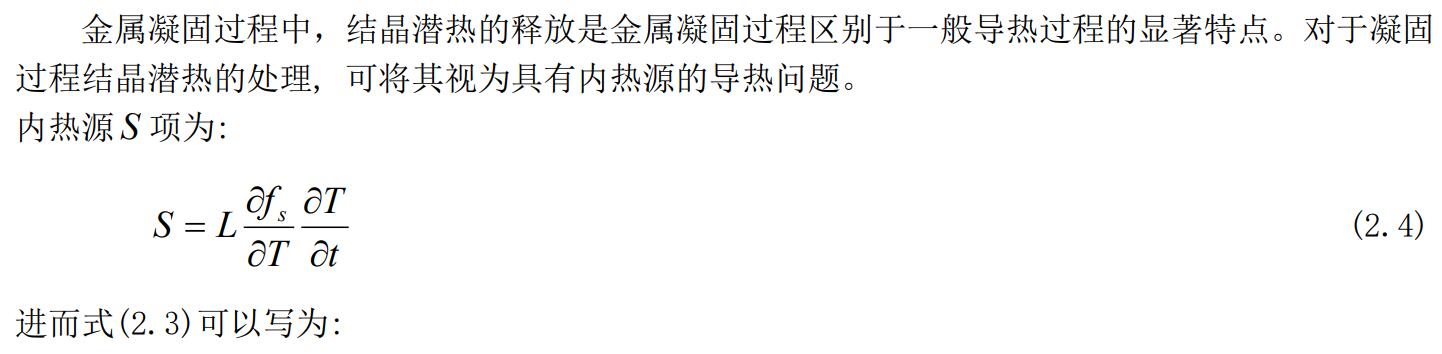

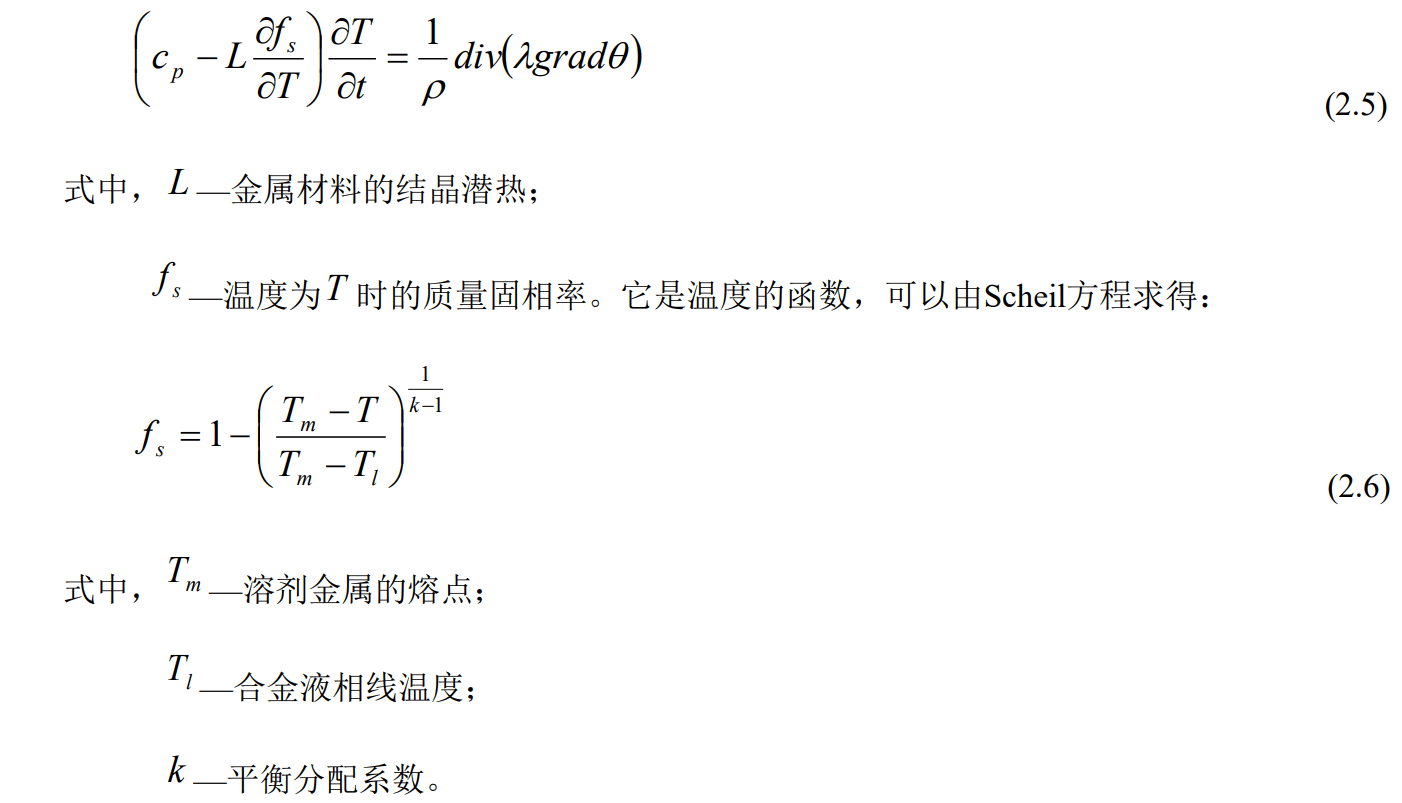

2.3凝固过程的数学模型 11

2.4凝固过程中常用的数值模拟方法 13

2.5本章小结 14

第三章多连体铝合金铸件的工艺特点和模型前处理 16

3.1多连体铸件的工艺特点 16

3.2薄壁多连体铸件的铸造难点 17

3.3模型网格的划分 17

3.4网格划分所遵循的原则 17

3.5前处理参数的确定 20

3.6本章小结 22

第四章 数值模拟的结果分析和方案改进 23

4.1 原件铸造过程数值模拟结果分析 23

4.2 对原工艺的优化方案 27

4.3 经济性分析 32

4.4 本章小结 32

结论 34

参考文献 35

致谢 38

摘 要

本课题以单件质量260kg的AlSi7Mg材质的薄壁大型筒形铸件为研究对象。

由于传统的铸造工艺需要对铸件进行反复的改进优化,这样不仅效率低且浪费资源。procast数值模拟技术具有精确度较高,模拟效率高等特点,本课题采用12.0版本的procast对AlSi7Mg材质的低压工艺铝合金铸件进行铸造过程的模拟和分析,主要取向于充型和凝固过程的分析。通过过程中的模拟和最终的缺陷成果对比,旨在对铝合金铸件可能产生的缩松缩孔等缺陷进行预测,针对缺陷提出优化方案,提高生产效率和铸件质量。本课题的主要内容如下:

采用ug三维造型软件对铸件进行造型和优化,划分面、体网格的设计过程要在procast中完成。定义材料、换热系数设置、边界条件设置和运行参数设置的前置处理过程紧随其后。

利用procast软件对铝合金铸件进行数值模拟,结合温度场过程分析和结果缺陷预测,对凝固的第一个和第二个过程中场的变化分析,判断评估铸件出现缩松缩孔的可能性并且判断缺陷发生的数量和位置,从而对铸造提出优化方案。

缺陷分析后发现,由于铸件结构复杂且壁厚处较多,采用壁厚处加冷铁且增加冒口增加缩补的优化方案,减少了缺陷数量,提高了铸造质量。值得注意的是优化过程中采用了虚拟砂箱的设计大大减少了模拟时间,提高了模拟效率。

关键词:低压铸造;数值模拟;procast;凝固过程;缺陷预测

Abstract

This project takes the thin-walled large-size cylindrical casting with a single piece mass of 260kg AlSi7Mg as the research object.

Because the traditional casting process needs to be improved and optimized repeatedly, the former is a waste of efforts. There is a trait that numerical simulation technology is accurate and active. In this paper, the processes of aluminum alloy castings were analyzed by numerical simulation. Based on the simulation process and results, the possible shrinkage porosity and other defects of aluminum alloy castings are predicted and propose optimization plan to improve production efficiency and casting quality. The main contents of this topic are as follows:

The casting was molded and optimized by using ug 3d modeling software, and the exported file was imported into procast12.0 for surface grid and volume grid division. Then the pretreatment setting is carried out, that is, defining the material, heat transfer coefficient setting, boundary condition setting and operation parameter setting.

Numerical simulation of aluminum alloy casting was carried out by using procast software, combined with temperature field process analysis and result defect prediction. Through the active change of the t-field in the processes, the disadvantages in the casting were analyzed. Then The optimization scheme for casting was put forward.

After defect analysis, it was found that due to the complex structure of casting and the large number of wall thickness, the optimization scheme of adding cold iron at the wall thickness and increasing the riser to increase shrinkage filling was adopted to reduce the number of defects and improve the casting quality. It is worth noting that the design of virtual sand box in the optimization process greatly reduces the simulation time and improves the simulation efficiency.

Key Words:Low pressure casting; The numerical simulation; procast; The solidification process;Defect prediction

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: