低温气体渗碳对304不锈钢应力腐蚀开裂的影响毕业论文

2020-04-15 16:53:19

摘 要

304奥氏体不锈钢(Austenitic Stainless Steel,ASS)具有优异的耐腐蚀性和韧性,因此被广泛应用于石油、化工、核电等行业,但其强度和硬度较低。若材料不经过特殊处理则无法用于制造承受重载和耐磨的零部件及设备。为了提高奥氏体不锈钢的耐磨损性的同时不降低其自身优异的耐蚀性,可以用低温气体渗碳表面强化技术(Low Temperature Gas Carburizing Surface Strengthening,LTGCSS)对其进行强化。LTGCSS是将C原子固溶于奥氏体基体形成一种具有非常好的机械性能与耐腐蚀性能的扩张奥氏体(S相)。

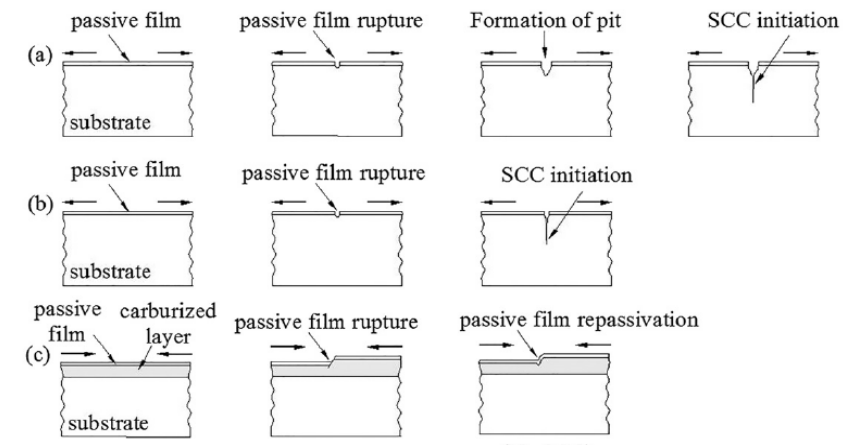

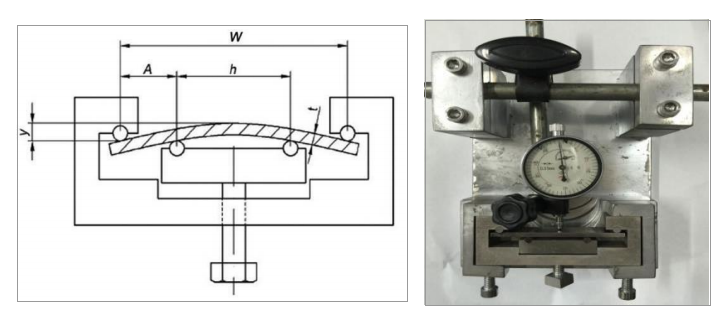

本文利用四点弯曲加载装置,结合ASTM G36 应力腐蚀开裂实验方法,对 304ASS及其渗碳层 0、5、15 μm 深度位置在 90、150、220 MPa 应力水平下的抗应力腐蚀开裂(Stress Corrosion Cracking,SCC)性能进行研究。试验采用了低温气体渗碳工艺对304ASS进行渗碳处理,利用光学显微镜(Optical Microscopy,OM)对处理后的试样形貌进行观察,并结合试样渗碳层不同深度位置的残余应力、物相结构和碳浓度,对渗碳层表面进行特征分析。通过扫描电子显微镜观察经SCC后试样表面的腐蚀形貌。SCC实验表明,同等拉伸应力水平下,304ASS相对其渗碳层,具有较高的应力腐蚀门槛值。点蚀是促成应力腐蚀试验中裂纹萌生的主要原因之一,拉伸应力作用下,点蚀底部发生应力集中,当应力达到应力腐蚀门槛值KISCC 时,在此处优先萌生微观裂纹,作为宏观裂纹扩张的前兆。

关键词:奥氏体不锈钢,低温气体渗碳,表面强化,应力腐蚀开裂

Abstract

304 austenitic stainless steel has excellent corrosion resistance and toughness, so it is widely used in petroleum, chemical industry, nuclear power and other industries, but its strength and hardness are low. If the material is not specially processed, it can not be used to manufacture parts and equipment that can withstand heavy load and wear resistance. In order to improve the wear resistance of austenitic stainless steel without reducing its excellent corrosion resistance, low temperature gas carburizing surface strengthening technology can be used to strengthen austenitic stainless steel. LTGCSS is an expanded austenite (S phase) formed by dissolving C atoms in austenite matrix, which has excellent mechanical and corrosion resistance.

In this artical, stress corrosion cracking (SCC) resistance of 304ASS and its carburized layer at depths of 0, 5 and 15 μm at stress levels of 90, 150 and 220 MPa was studied by means of four-point bending loading device and stress corrosion cracking test method of ASTM G36. The low temperature gas carburizing process was used to carburize 304ASS. Optical Microscopy (OM) was used to observe the morphology of the treated samples, and the characteristics of the surface of the carburized layer were analyzed according to the residual stress, phase structure and carbon concentration at different depths of the carburized layer. The corrosion morphology of the sample surface after SCC was observed by scanning electron microscopy. SCC experiments show that 304ASS has a higher stress corrosion threshold than its carburized layer at the same tensile stress level. Pitting corrosion is one of the main causes of crack initiation in stress corrosion test. Under tensile stress, stress concentration occurs at the bottom of pitting corrosion. When stress reaches the threshold value of stress corrosion (KISCC), micro-cracks are preferentially initiated here as a precursor of macro-crack expansion.

KEYWORDS: Austenitic stainless steel ; LTGCSS; Surface strengthening ; Stress corrosion cracking

目录

第1章 绪论 3

1.1课题研究背景: 3

1.2 奥氏体低温表面强化技术进展: 4

1.2.1低温离子渗碳/氮表面强化技术: 4

1.2.2低温气体渗碳表面强化技术: 5

1.3应力腐蚀: 6

1.4 低温气体渗碳工艺对应力腐蚀的影响 7

1.5主要研究内容及方法 8

1.5.1课题研究内容 8

1.5.2主要研究手段 9

第2章 试验与方法 9

2.1 引言: 10

2.2 试验内容和方法: 10

2.2.1试验材料与试样制备: 10

2.2.2 低温气体渗碳试验过程: 10

2.2.3 测量低温渗碳层性能表征的方法: 11

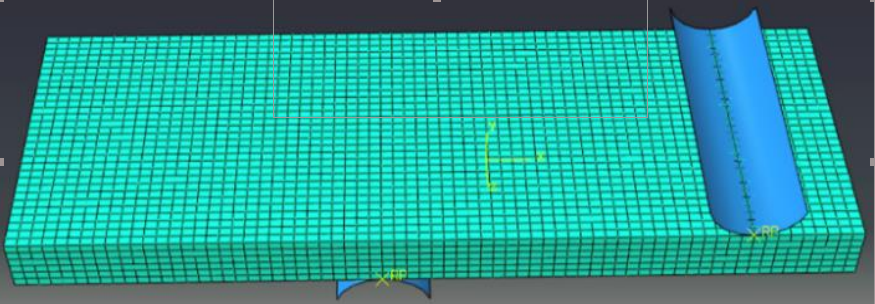

2.2.4四点弯曲试验: 13

2.2.5 SCC试验: 14

第3章 结果和讨论 15

3.1渗碳层表面特征分析: 15

3.2 基于四点弯曲实验的渗碳层力学性能: 17

3.3抗SCC性能比较: 18

3.4 SCC实验后的试样表面特征的比较: 20

3.5 结论: 24

第4章 经济效益评价 25

第5章 未来与展望 27

致谢 28

参考文献 29

第1章 绪论

1.1课题研究背景:

奥氏体不锈钢钢(Austenitic Stainless Steel,ASS)的主要化学成分是Cr、Ni等元素在Fe中形成的间隙固溶体[1]。因其良好的耐腐蚀性、韧性和可加工性能,被广泛应用于核工业、化学工业、机械工业等各大领域。每年奥氏体不锈钢的生产量约占不锈钢总产量的 70%,在工业中应用达到 80%以上[2-3]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示: