水下压缩机系统可靠性分析及优化毕业论文

2021-11-29 21:21:07

论文总字数:33597字

摘 要

在水下生产系统拥有较大生产量需求的今天,水下生产系统当中的故障可能引发整个系统的失效,无论从经济性还是安全性,水下生产系统的可靠性分析越来越不能轻易被忽视。作为水下生产系统最重要的一环--水下压缩系统当中的故障也可能直接影响水下生产系统的正常工作。故对水下压缩系统进行可靠性分析成为保证水下生产系统的重要任务。对水下压缩系统的可靠性分析关键步骤就是制作可靠性表格,绘制故障树,结合数据进行分析并提出优化方案来提升水下压缩系统的可靠性。

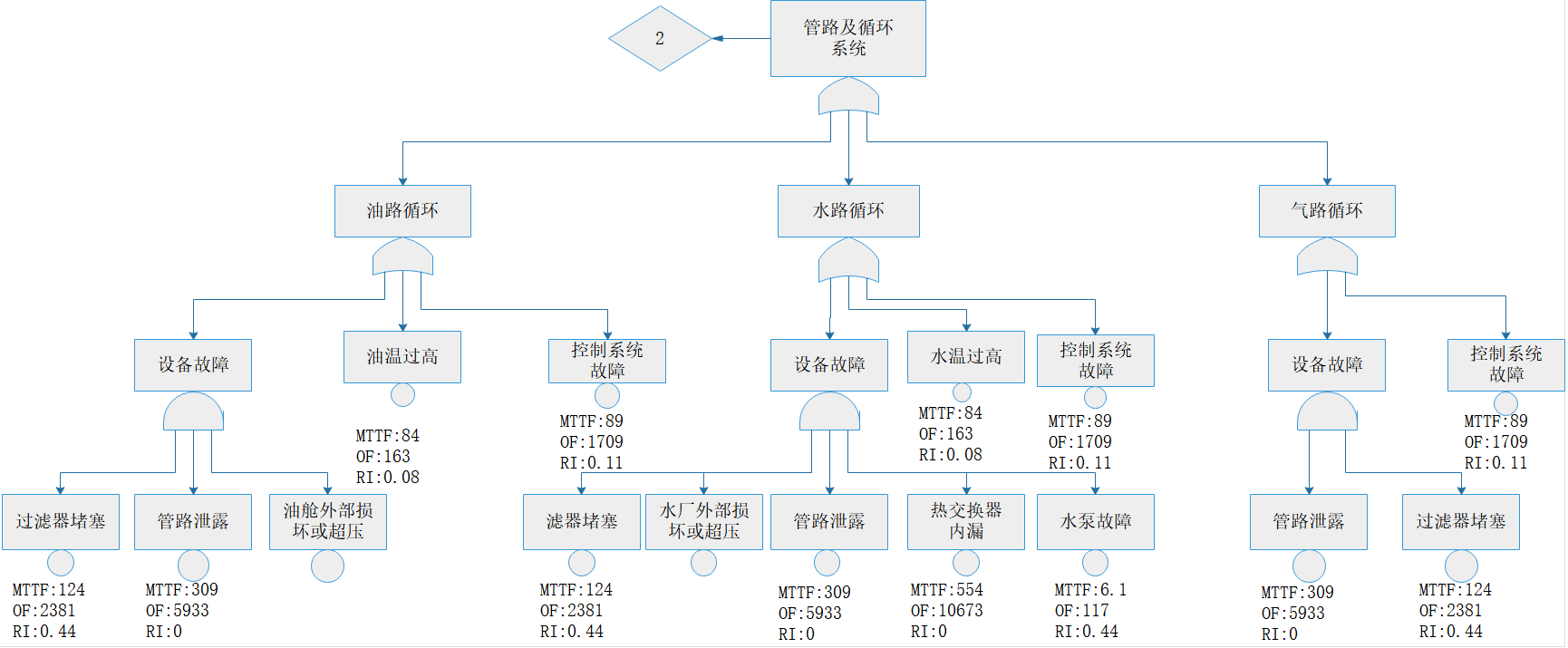

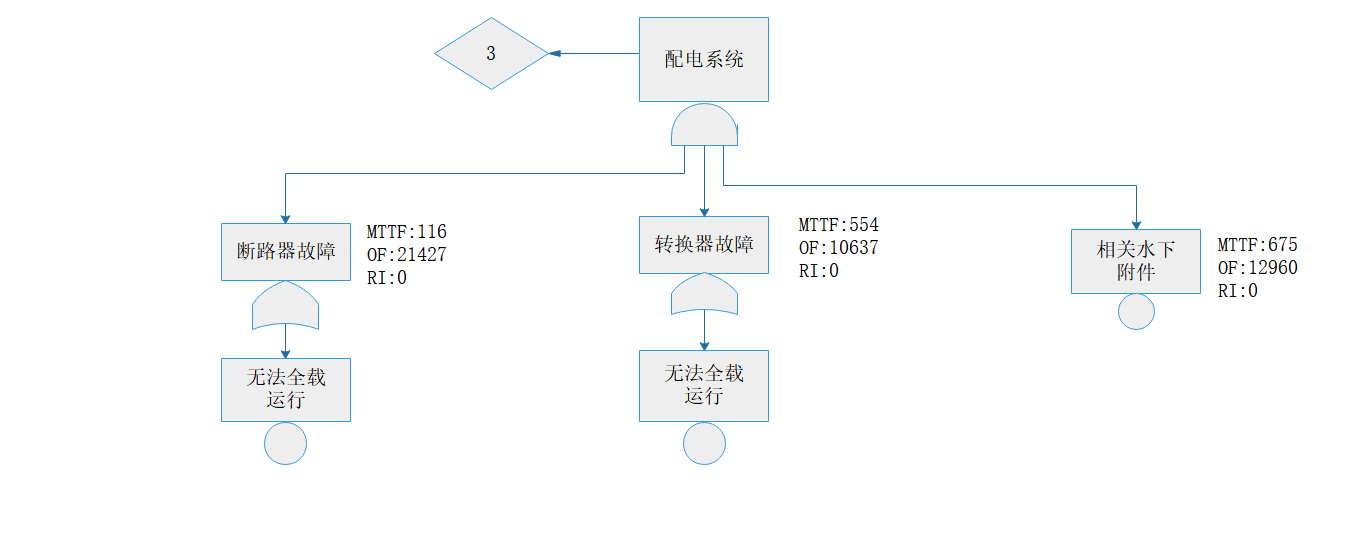

本文将通过对水下压缩系统进行分块处理,将水下压缩系统分为几个子系统。结合分出的子系统,分析每个子系统可能存在的故障,整理零部件的失效模式,学习Ballast System FMEA当中的可靠性分析表格,做出水下压缩系统的可靠性分析表格。在表格做出以后,对每个子系统的每个故障进行详细的描述,总结故障发生的原因,研究故障可能对系统带来的影响,适当的提出解决方法。

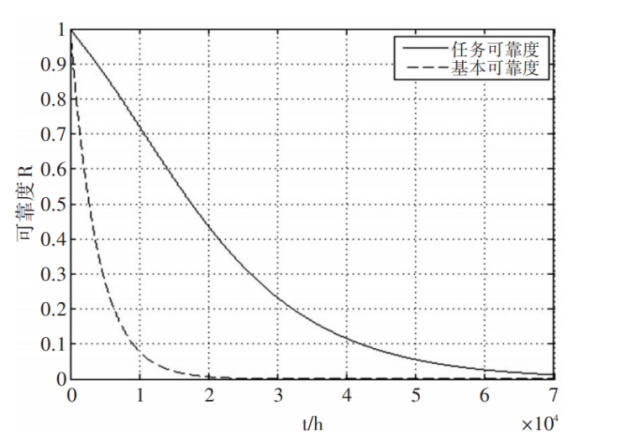

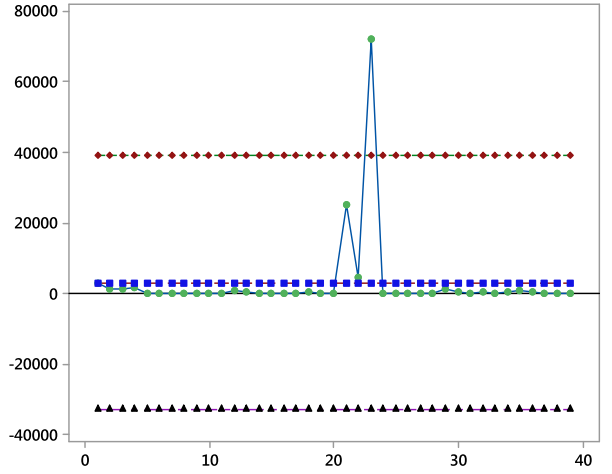

本文还将绘制故障树来进行可靠性分析。选用EdrawMax软件来构建故障树模型,根据做过的可靠性分析表格来绘制水下压缩系统的故障树,并查阅相关资料补充数据。并通过对水下压缩系统的故障树进行数据的分析,提出优化方法。通过提出的优化方法,可以将整个水下压缩系统的故障率降低,延长系统的工作时间。通过优化方法,系统的可靠度最大可以从0.45上升至0.95,优化幅度达到52%。

关键词:水下压缩系统、可靠性分析表格、故障树分析、系统的优化

Abstract

Today, when the underwater production system has a large production demand, the failure of the entire system may be caused by the failure of the underwater production system. The reliability analysis of the underwater production system cannot be easily ignored in terms of economy or safety. As the most important part of the underwater production system, the fault in the underwater compression system may directly affect the normal operation of the underwater production system. Therefore, the reliability analysis of the underwater compression system becomes an important task to ensure the underwater production system. The key steps for the reliability analysis of the underwater compression system are to make a reliability table, draw a fault tree, analyze the data and put forward an optimization plan to improve the reliability of the underwater compression system.

In this paper, the subsea compression system is divided into several subsystems through block processing. Based on the selected subsystems, analyzed the possible faults of each subsystem, sorted out the failure modes of parts and components, learned the reliability analysis table of Ballast System FMEA, and made the reliability analysis table of the underwater compression System. After the table is made, each failure of each subsystem is described in detail, the cause of the failure is summarized, the possible impact of the failure on the system is studied, and the appropriate solution is proposed.

This paper will also draw a fault tree for reliability analysis. EdrawMax software was used to build the fault tree model, and the fault tree of the underwater compression system was drawn according to the reliability analysis table, and relevant data were consulted to supplement the data. By analyzing the data of fault tree of underwater compression system, an optimization method is proposed. Through the optimization method, the failure rate of the whole underwater compression system can be reduced and the working time of the system can be extended. Through the optimization method, the maximum reliability of the system can be increased from 0.45 to 0.95, with an optimization range of 52%.

Key Word:Subsea compression system;Reliability analysis form;Fault tree analysis(FTA);System optimization

目 录

第1章 绪论..................................................................................................................1

1.1 研究目的及意义.................................................................................................1

1.2 国内外研究现状.................................................................................................1

1.2.1 动态模型......................................................................................................1

1.2.2 不确定性模型..............................................................................................2

1.2.3 柔性模型......................................................................................................2

1.2.4 加速寿命测试..............................................................................................2

1.3 对压缩机系统的可靠性分析.............................................................................2

1.4 论文结构内容.....................................................................................................3

第2章 可靠性分析介绍..............................................................................................4

2.1 可靠性分析.........................................................................................................4

2.2 可靠性分析相关的模型和数据.........................................................................4

2.2.1 微布尔分布模型..........................................................................................4

2.2.2 混合微布尔模型..........................................................................................5

2.2.3 伽马分布模型..............................................................................................6

2.2.4 竞争失效模型..............................................................................................7

2.3 数据的选择.........................................................................................................8

2.3.1 可靠度和不可靠度百分数..........................................................................8

2.3.2 总故障停机时间..........................................................................................8

2.3.3 故障频率......................................................................................................9

2.3.4 平均失效时间..............................................................................................9

2.3.5 最小和最优的平均失效时间......................................................................9

2.4 本章小结.............................................................................................................9

第3章 压缩机系统的可靠性分析.............................................................................10

3.1 水下压缩机系统................................................................................................10

3.2 工作系统............................................................................................................10

3.2.1 蒸汽轮机.....................................................................................................10

3.2.2 压缩机.........................................................................................................12

3.3 管路及循环系统................................................................................................15

3.3.1 油路循环系统.............................................................................................15

3.3.2 水路循环系统.............................................................................................16

3.3.3 气路循环系统.............................................................................................17

3.4 配电系统............................................................................................................18

请支付后下载全文,论文总字数:33597字

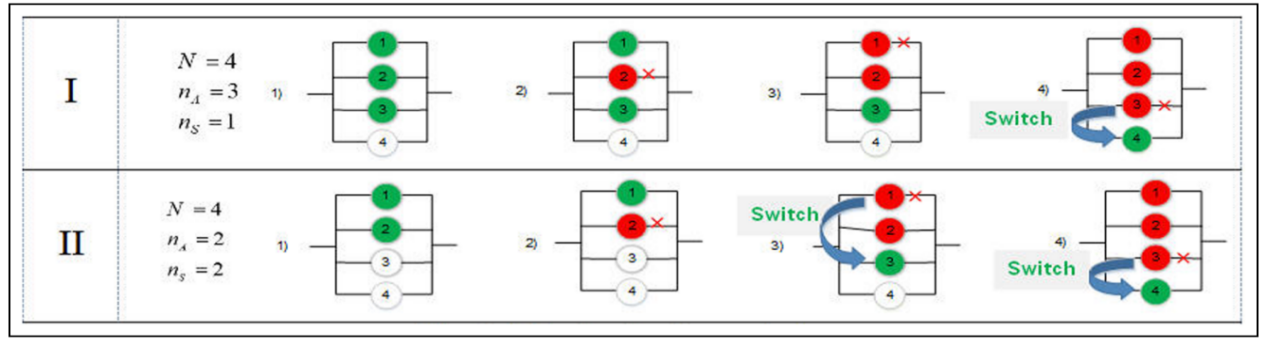

相关图片展示: