Al2La合金的熔炼制备和腐蚀行为研究毕业论文

2020-07-06 18:33:28

摘 要

镁合金物理性能优良,具有比重小,塑性好,易加工等优点,是广泛使用的绿色轻型结构材料。然而镁合金的化学活泼性高,耐蚀性能差制约了其发展,在镁合金中加入稀土元素,可以改善其化学成分与微观组织结构,进而改善耐蚀性,已经越来越多的应用到镁合金。在工业常用的AE系合金中添加La可以提高耐蚀性,高温力学性能与热稳定性。通过La的变质作用与净化作用可改善镁合金的流动性从而提高其抗蠕变性能与拉伸性能。本文以稀土镁合金中的Al2La相为主,进一步优化Al2La的熔炼方法,采用物理表征和多种电化学测试方法探讨其微观结构和在氯化钠中的腐蚀行为。

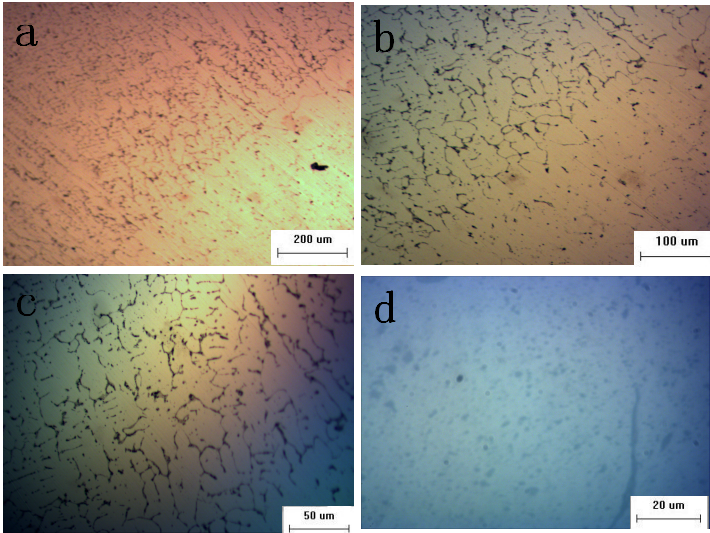

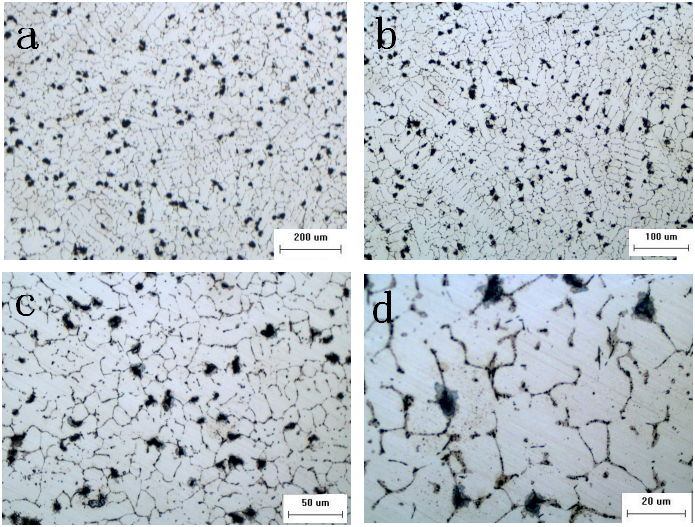

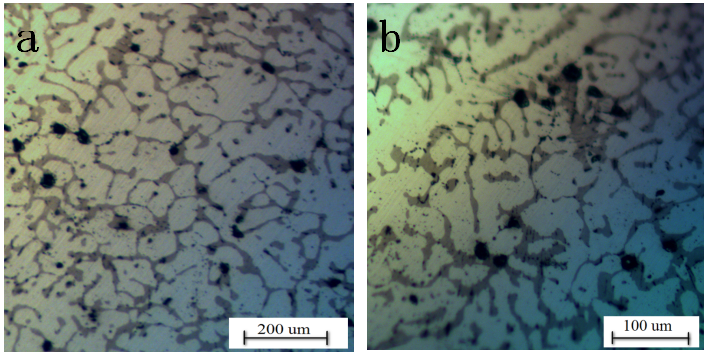

我们采用了非自耗真空熔炼技术熔炼出Al2La,采用金相分析、XRD、SEM和EDS物理表征手段研究了Al2La的微观结构与化学成分。结果表明所得Al2La合金并非简单的单相结构,除了Al2La相还存在未反应La相,多余的La相在晶界处析出。我们对AE44合金中存在的主要次生相进行了分析,采用电化学测试手段,如开路电位测试、Tafel极化曲线分析了Al2La、Mg17Al12、AE44三种合金的电化学行为。结果表明Al2La的腐蚀电流和腐蚀电位都最低,耐蚀性能最好,且三种合金的耐蚀性高低顺序为Al2La>Mg17Al12>AE44。

关键字:稀土元素 Al2La 微观结构 电化学腐蚀

Melting preparation and corrosion behavior of Al2La Alloys

Abstract

Magnesium alloy has been used in industry as it has excellent physical properties, small specific gravity, good plasticity, easy processing. However, the high chemical reactivity of magnesium alloys and the poor corrosion resistance restrict their development. The addition of rare earth elements to magnesium alloys can improve the chemical composition and microstructure of the magnesium alloys. In order to improve corrosion resistance that rare earth elements have been increasingly applied to magnesium alloys. Adding La to Magnesium-based alloys commonly used in industry can reinforce corrosion resistance, high-temperature mechanical properties and thermal stability. The metamorphism and purification of La can enhance the flowability of magnesium alloys and increase their creep resistance and tensile properties. In this work, the Al2La phase in rare earth magnesium alloys is mainly used to further optimize the smelting process of Al2La. The physical characteristics and various electrochemical testing methods are used to explore the microstructure and corrosion behavior in sodium chloride.

We used the non-consumable vacuum melting technology to prepare Al2La. The microstructure and chemical composition of Al2La are characterized by means of metallographic analysis, XRD, SEM and EDS. The results show that the obtained Al2La alloy is not a single-phase structure consisting of Al2La and La phases, and the redundant La phase precipitates at the grain boundaries. The electrochemical behaviors of Al2La, Mg17Al12 and AE44 alloys are analyzed by electrochemical test methods such as open circuit potential test and Tafel polarization curve. The results show that the corrosion current and corrosion potential of Al2La are the lowest, and the corrosion resistance is the best. The corrosion resistance of different alloys is following the order of Al2La>Mg17Al12>AE44.

Key words: Rare earth elements Al2La Microstructure Electrochemical corrosion

目录

摘要Ⅰ

AbstractⅡ

第一章 绪论 1

1.1引言 1

1.1.1稀土元素在镁合金中的作用 1

1.1.2稀土镁合金研究和应用 1

1.2镁合金腐蚀和防护 2

1.2.2镁合金的发展与应用 2

1.2.2镁合金腐蚀机理 2

1.2.3 镁合金的防护技术 2

1.3 镁铝基稀土合金 3

1.3.1 Mg-Al基稀土合金概况 3

1.3.2 AE44合金的研究 4

1.3.3 La对Mg-Al合金的作用 4

1.4 Al2La合金 5

1.4.1 稀土元素对铝合金的影响 5

1.4.2 Al-La的显微组织和金属间化合物 5

1.4.3 Al-La的制备 5

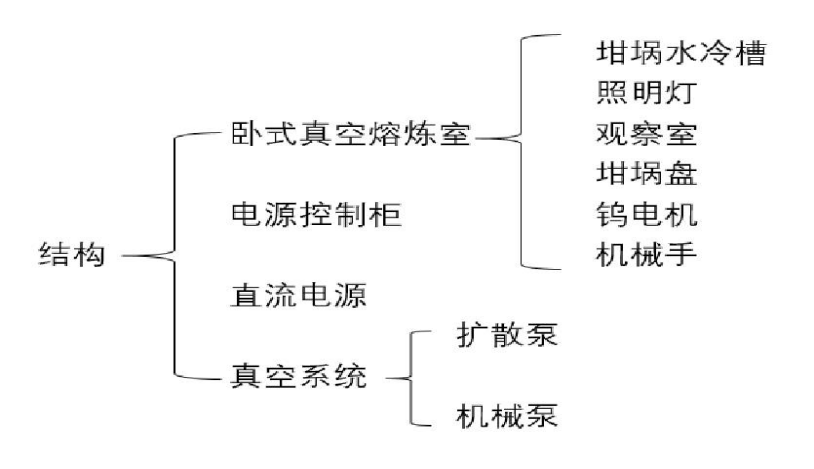

第二章 实验方法 7

2.1实验主要仪器和样品 7

2.2 实验材料 8

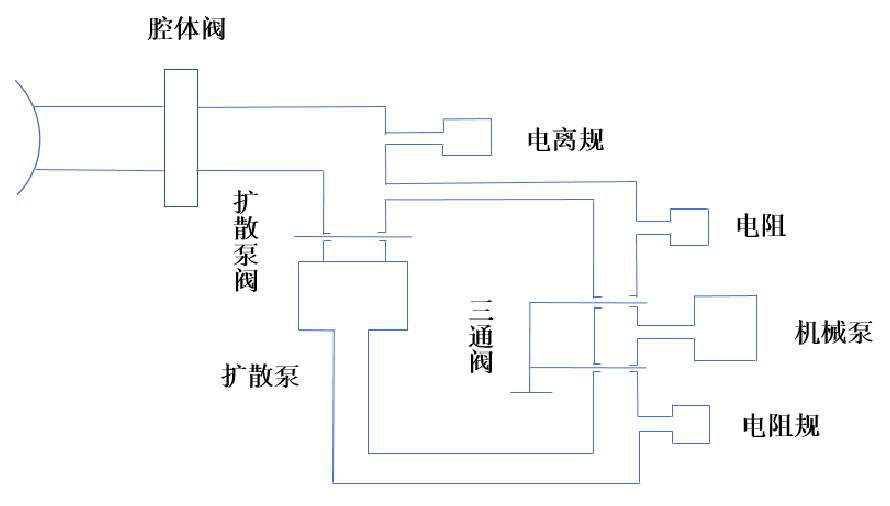

2.3 实验内容 9

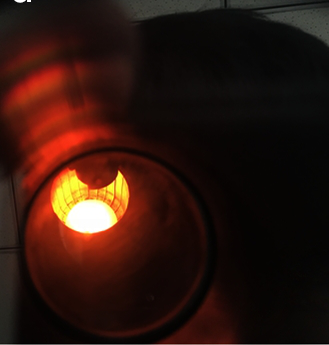

2.3.1 Al2La的熔炼 9

2.3.2 Al2La的物理表征 10

2.3.3 电化学测试 11

2.3.4 合金的腐蚀形貌 12

第三章 实验结果与分析 13

3.1 Al2La的微观结构与化学成分 13

3.2 Al2La、Mg17Al12、AE44的腐蚀电化学行为 19

3.3 Al2La、Mg17Al12、AE44的腐蚀形貌 21

第四章 结论与展望 25

4.1 结论 25

4.2展望 26

参考文献 27

致谢 29

第一章 绪论

1.1引言

稀土元素具备固溶强化和析出强化作用,能够减少金属材料中有害金属的危害性。镁合金的耐腐蚀性能不好,稀土元素的加入可以改善镁合金的微观结构和组织,提高其在高温下的稳定性,抗蠕变性能与抗拉伸性能。Mg-Al-RE基镁合金中的Al-RE金属间化合物具有很高的熔点,有优越的高温机械性能和良好的抗蠕变性且成本低廉,对镁合金高温性能有很好的强化作用。其中含La的镁合金在稀土元素含量增加时表现出最好的机械性能,所以La在Mg-Al-RE或Al-RE基合金中被广泛使用[1]。

相关图片展示: