TiTiN复合镀层导电耐蚀性能研究毕业论文

2020-06-07 21:11:37

摘 要

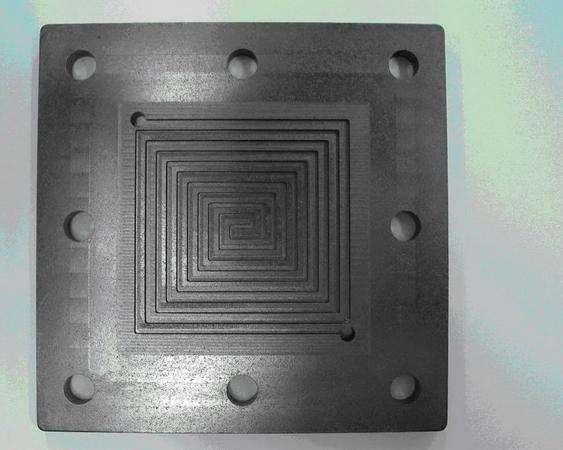

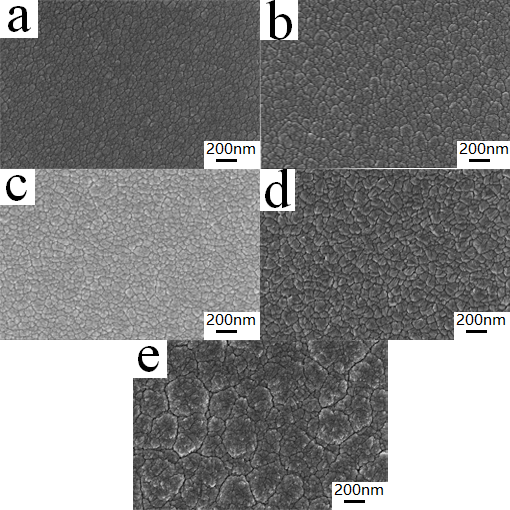

在人类社会面临化石能源储量越发减少和环境污染加剧的21世纪,找到环保的新型能源愈发紧迫。在此背景下,具绿色、高效、适用范围广的燃料电池成为了近二十年来的研究热点。首先,本文介绍了几种双极板的制造方法和使用的材料。然后,对采用磁控溅射离子镀在铝合金双极板镀上TiN镀层这种技术展开了深入的研究。经过扫描电子显微镜检测表明镀膜时间为60、120、180、240分钟的TiN镀层表面完整、颗粒度较细、结构致密。经过电化学实验测定TiN镀层的塔菲尔曲线表明镀膜时间为60分钟的TiN镀层耐腐蚀性能最好,120分钟次之。经过接触电阻实验表明当工作压强为140N/cm2时,镀膜时间为180分钟的TiN镀层的接触电阻最小,240分钟次之。经过电阻率测量实验表明镀膜时间为300分钟的TiN镀层的电阻率最低,240分钟次之。综合镀层的微观形貌、电化学腐蚀实验、接触电阻测量实验和电导率测量实验可以得出镀膜时间为120分钟和240分钟的TiN镀层的导电性和耐腐蚀性能最佳。

关键词: 双极板 TiN 导电性 耐腐蚀性

Research of the electrical conductivity and corrosion resistance of aluminum based TiN coating

Abstract

Human society face with problems of decreasing fossil energy reserves and weighted environmental pollution in twenty-first Century. to found environmentally friendly new energy has become a matter of urgency. In this context, the green, efficient and wide range of fuel cells has become the focus of research in the past twenty years. In this context, the fabrication methods and materials used for bipolar plates are introduced. Then, plating TiN coating on aluminum alloy bipolar plate by Magnetron sputtering ion plating has been studied deeply. Through scanning electron microscopy detection showed that the TiN coating of coating time was one、two、three and four hours has integral surface, small particle and compact structure. The Tafel curve of TiN coating showed that the corrosion resistance of TiN coating was the best when coating time was one hour, and it was two hours later. The contact resistance test shows that when the working pressure is 140N/cm2, the contact resistance of TiN coating with three hours coating time is minimum, and it was four hours later. The resistivity measurement shows that the resistivity of TiN coating is the lowest when the coating time is five hours,and it was four hours later. Comprehensive Microstructure of coating ,electrochemical corrosion experiments, contact resistance measurement experiment and conductivity measurement experiments show that the TiN coating with the coating time of two hours and four hours has the best conductivity and corrosion resistance.

Keywords: bipolar plate; TiN; conductivity ; corrosion resistance

目 录

摘 要 I

Abstract II

第一章 绪论 1

1.1 质子交换膜燃料电池 1

1.2 双极板的作用与未来 1

1.3 双极板的制造工艺 2

1.3.1 石墨/树脂双极板的制作工艺 2

1.3.2 金属双极板的制作工艺 2

1.4 双极板的制造材料 4

1.4.1石墨/树脂双极板 4

1.4.2金属双极板 4

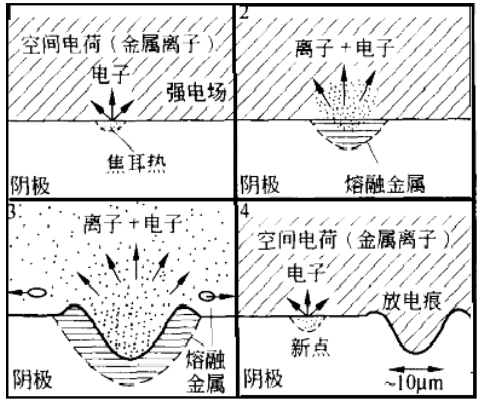

1.5 TiN镀层的导电性能及其腐蚀机理 5

1.6 TiN镀层的几种制备工艺 6

1.6.1 磁控溅射离子镀 6

1.6.2 多弧离子镀 6

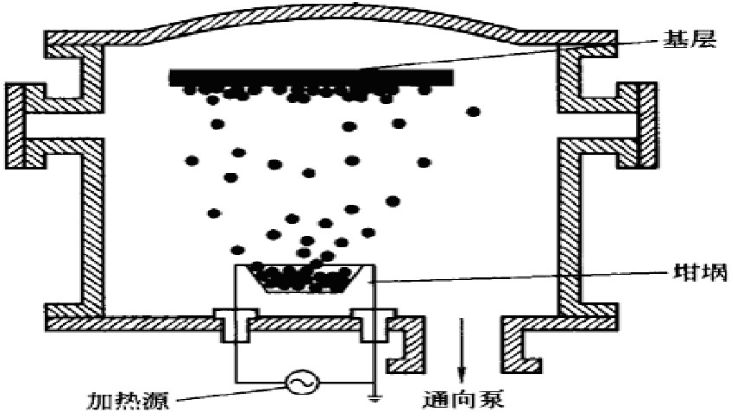

1.6.3 真空蒸镀 7

第二章 实验 9

2.1 TiN镀层的制备 9

2.2 TiN镀层的表征方法及原理 9

2.3 电化学腐蚀测试 10

2.4 导电性能测试 10

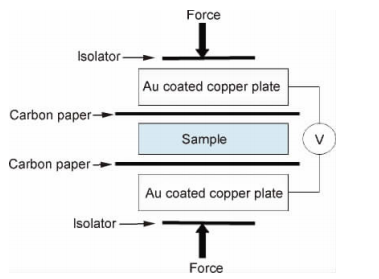

2.4.1 接触电阻 10

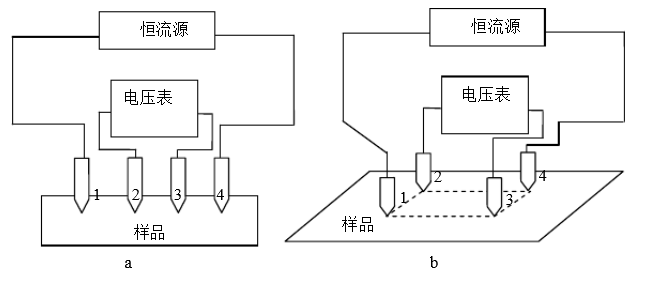

2.4.2 电阻率 11

第三章 结果与讨论 13

3.1 TiN镀层的微观结构检测 13

3.1.1 TiN镀层的SEM检测 13

3.1.2 TiN镀层的XRD检测 15

3.2 电化学腐蚀测试 17

3.3 导电性能测试 19

3.3.1 接触电阻 19

3.3.2 电阻率 20

第四章 结论 23

参考文献 26

致 谢 27

相关图片展示:

您可能感兴趣的文章

- 表面活性剂改性疏水性Cu2O量子点作为高效钙钛矿太阳能电池顶部空穴传输材料外文翻译资料

- Nb 和 Ni 共掺杂 Mg(0001)氢解离扩散的理论研究:外文翻译资料

- 低温固相法制备锂离子电池正极材料LiFeSO4F毕业论文

- 锂空气电池新型正极催化剂Gd2Zr2O7的制备与性能研究毕业论文

- 酸类添加剂对beta”-Al2O3电泳沉积成型法的影响毕业论文

- CuZr非晶合金中短程有序结构及其与玻璃形成能力的关系研究毕业论文

- 靶电流对多弧离子镀TiN镀层微观结构和性能的影响毕业论文

- 基于溅射离子镀技术的黄色系镀层制备及色彩表征毕业论文

- 电参数对铝合金汽缸微弧氧化陶瓷层性能的影响毕业论文

- 基于溅射离子镀技术的蓝色系镀层制备及色彩表征毕业论文