在模拟PEM燃料电池环境下垫片材料损伤研究毕业论文

2020-05-28 07:00:28

摘 要

燃料电池是一种能源,质子交换膜燃料电池也是其中一种,它是一种清洁、高效的电化学发电装置,近些年一直备受关注,国内对于燃料电池的运用已经成功的在一些高大上的项目上上马了,比如潜艇上、航空航天领域等等,更不用说生活的应用了:公共汽车、家庭电源、充电设备等等。尽管如此,对于燃料电池这一块仍然有许多瓶颈卡在那里,与此同时,国外的发展也很迅猛,每年都投入大量资金在里面搞科研,推动其更大范围的应用。

质子交换膜燃料电池(Proton Exchange Membrane Fuel Cell, PEM fuel cell)由于其独特的优点:操作温度低、效率高、零污染等,这就导致了其未来的发展潜力巨大,国内外不少企业看好这块蛋糕,投资巨大。而作为燃料电池的重要组件——弹性体垫片材料,由于其长期处于燃料电池内部一种偏酸性、潮湿并且承受一定温度载荷以及机械压缩载荷的环境中,这要求弹性体垫片材料具有良好的化学及机械稳定性,对于这一块,长期由国外市场垄断,价格居高不下,面对挑战,国内目前正在组织相关领域的专家公关,目前已经取得了重大进展,如果弹性体垫片材料出现老化损伤甚至失效,使得弹性体垫片材料机械性能急剧下降,甚至引发反应气体泄漏或相互混合,这会直接影响PEM燃料电池的安全、高效、持久运行。因此,在PEM燃料电池内部环境中,弹性体垫片材料的化学及机械稳定性决定着整个PEM燃料电池的正常运行。

本文针对作为密封材料硅橡胶在质子交换膜燃料电池内部环境中的化学及机械性能进行了一些浅薄的研究,以此作为对质子交换膜燃料电池在密封垫片材料的使用提供一些小小的建议,截止实验完成为止,主要的工作和得到的结论如下:

(1)在真实的模拟质子交换膜燃料电池内部的工作环境,配制了与其工作环境相似的常规溶液和加速溶液,比便于研究在该工作环境下弹性体材料的老化行为。

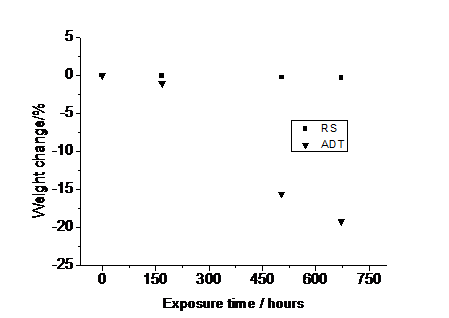

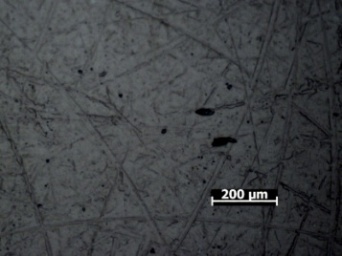

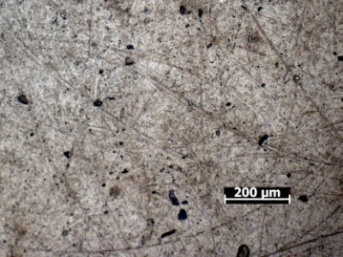

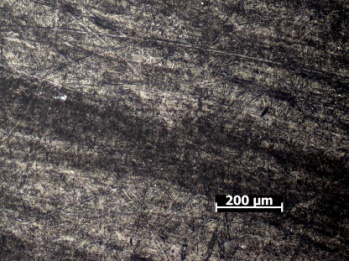

(2)在RS和ADT老化环境中硅橡胶材料的重量变化和外观的变化方向,运用光学显微镜和重量监测进行了分析研究,结果表明,随着老化时间的增加,试样的老化程度不断加速,重量损失越来越明显,材料表面形貌由刚开始的光滑慢慢变的粗糙最后到产生裂纹、扩展裂纹,最终会导致试样的断裂。

(3)操作环境对质子交换膜燃料电池垫片材料的机械性能影响很大,在我们所做的机械性能试验中,得到的结论表明了一点:在老化环境H 浓度相同的条件下,老化时间越长试样机械性能的变化越明显。

关键词:质子交换膜燃料电池;垫片材料;老化;机械性能

ABSTRACT

Fuel cell is a kind of high efficiency and clean electrochemical generator, which has been widely paid attention at home and abroad in recent years. This report describes in detail the background of the development of fuel cells, classification, and various types of fuel cell operating principle and its advantages and disadvantages. Fuel cells have been successfully used in aerospace, submarines, buses, home power and charging equipment and other fields, but there are still a number of technical bottlenecks constraining the development of fuel cells. At the same time, at home and abroad are also actively exploring the fuel cell, to promote its wider application.

Proton exchange membrane fuel cell (PEMFC) because of its unique advantages: low operating temperature, high efficiency, zero pollution and so on, so it has wide application prospect and the development of the market. As a fuel cell of the important components -- the elastomeric gasket material, due to its long in a within the fuel cell was a kind of acidic, moist and under certain temperature load and the mechanical compression load environment, which requires elastomeric gasket material with good chemical and mechanical stability. If appear the elastomeric gasket material aging damage or even failure, making the elastomeric gasket material mechanical performance declined sharply, and may even trigger a reaction gas leakage or mixed with each other, which will directly affect the PEM fuel cell safe, efficient and sustainable operation. Therefore, the chemical and mechanical stability of the elastomer gasket material in the PEM fuel cell environment is essential for the safe, efficient and durable operation of the entire fuel cell.

In this paper, the chemical and mechanical stability of silicone rubber as sealing material in PEM fuel cell environment is studied, which provides a guide for the use of PEM fuel cell. The main work and conclusions of this paper are as follows:

(1) In the service environment of PEM fuel cell, the test solution and accelerated solution are formulated to study the aging behavior of the material in the environment.

(2) With weight monitoring and an optical microscope of silicone rubber materials in RS and ADT aging environment changes in weight and the morphology of the development trend of the study, the results show that, with prolonging of aging time, the increase of the solution concentration sample aging degree will continue to increase, increase the weight loss, material surface micro topography from initially smooth gradually become rough to crack generation, propagation, until the specimen fracture.

(3) The results show that the operating environment of the fuel cell has an important influence on the mechanical properties of the gasket materials. The increase of H concentration in the aging time and aging environment can accelerate the mechanical property of the sample in different degrees.

Keywords: PEM fuel cell; gasket material; aging; mechanical property

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1 引言 1

1.2 燃料电池研究进展 2

1.3 PEM燃料电池研究进展 4

1.3.1 PEM燃料电池工作原理 4

1.3.2 PEM燃料电池发展与研究现状 5

1.4 弹性体材料 7

1.4.1 弹性体材料概述 7

1.4.2 弹性体材料损伤研究进展 7

1.5 本文主要研究内容 8

第二章 弹性体垫片材料老化试验及其化学损伤 10

2.1 引言 10

2.2 PEM燃料电池垫片材料老化试验及其化学损伤 10

2.3 RS与ADT溶液配制方案 12

2.3.1 目标溶液配制 12

2.3.2常规(RS)溶液的配制 12

2.3.3 ADT溶液的配制 13

2.4 试验结果与分析 14

2.4.1 重量损失分析 14

2.4.2 试样微观形貌分析 15

2.5 本章小结 17

第三章 弹性体垫片材料机械稳定性研究 18

3.1 引言 18

3.2 机械性能试验 18

3.2.1 试样准备 18

3.2.2 试验方法 19

3.2.3 力学性能试验 20

3.3 试验结果及分析 23

3.3.1 拉伸应力应变试验结果及分析 23

3.3.2 压缩永久变形试验结果及分析 24

3.3.3 压缩应力松弛试验结果及分析 25

3.4本章小结 26

第四章 结论与展望 28

4.1 结论 28

4.2 展望 29

参考文献 31

致 谢 34

第一章 绪论

1.1 引言

能源也称之为能量资源或者能源资源,能源分四种:一次能源,二次能源,其他新能源和可再生能源。我们主要运用的是一次能源,二次能源,一次能源包含煤炭、天然气、核能、太阳能等等;二次能源主要运用电力、热力、成品油等等。

中国是一个能源生产和消费大国,作为世界上最大的发展中国家,我们的能源运用居世界前列,中国是一个以一次能源——煤炭为主要能源的国家,环境污染与发展经济的矛盾尤其突出,最近这些年,煤炭安全问题已经成为社会乃至国家关注的焦点,已经成为了中国发展的瓶颈,尤其是成为了中国战略安全的隐患。

相关图片展示: