连续压痕法奥氏体不锈钢接头残余应力毕业论文

2020-07-15 21:10:40

摘 要

残余应力是工件破坏的重要原因之一。但是就目前而言,我们对于工件内部的残余应力的检测还并没有很完善,而有损检测又具有一定的局限性,无损检测虽然对试件没有损害,但在精度上或者在成本上很难令人满意。我们本文所研究的压痕法是在一种在硬度法的基础上起来的一种新方法,由于压痕法操作简单,比较容易实现,而且所需成本也比较低廉,但是可信程度比较高,总体所需代价较低,因此我们现在在各行各业都有着广泛的应用,在科研界已经成为一种可靠的研究手段。

本文就压痕法测量残余应力的理论方面进行了研究。采用有限元分析法对压痕法的简化模型进行数值模拟,先后进行了模型的建立,模型的验证,以及对我们所要求取的无量纲函数进行了确定,并且我们介绍了测量残余应力的反演方法,可以得到我们所需求的残余应力数值。最后通过实验数据的验证,得到了无量纲函数系数的关系,最后我们又对真实材料304不锈钢进行验证,进一步验证了此方法的合理性。

关键词: 模型建立 残余应力 无量纲函数 压痕法

Abstract

Residual stress is one of the important causes of workpiece failure. However, at present, we have not yet perfected the detection of the residual stress inside the workpiece, and the loss detection has certain limitations. Although the non-destructive testing has no damage to the test piece, it is very accurate or cost-effective. Unsatisfactory. The indentation method we studied in this paper is a new method based on the hardness method. Because the indentation method is simple and easy to implement, and the cost is relatively low, but the credibility is relatively high, the overall cost is low, so we now have a wide range of applications in all walks of life and have become a reliable research tool in the research community.

In this paper, the theoretical aspects of indentation measurement of residual stress are studied. The finite element analysis method was used to simulate the simplified model of the indentation method. The establishment of the model, the validation of the model, and the determination of the non-dimensional function required by us were determined. And we introduced the measurement of the residual stress. The method of performance can get the residual stress value we need. Finally, through the verification of experimental data, the relationship of dimensionless function coefficients was obtained. Finally, we verify the authentic material 304 stainless steel and get a reasonable result. The results of this study are of great significance for the further development and engineering application of the indentation method.

Key Words: Residual stress;The indentation method;The establishment of the model;Timensionless function

目 录

摘要 I

Abstract II

第1章 绪 论 1

1.1 课题意义 1

1.2 残余应力的产生原因 1

1.2.1 不均匀变形 1

1.2.2 相变或沉淀析出引起的体积变化 2

1.3 残余应力的危害 2

1.3.1 残余应力对金属材料屈服极限的影响 2

1.3.2 残余应力对构件变形的影响 2

1.4 残余应力的测量方法 2

1.4.1 磁测法 2

1.4.2 超声波测量法 3

1.4.3 扫描电子声显微镜测量法 3

1.4.4 盲孔法 4

1.5 压痕法的发展历程 4

1.6 本课题拟采用的技术手段 5

第2章 压痕接触的理论分析 7

2.1 引言 7

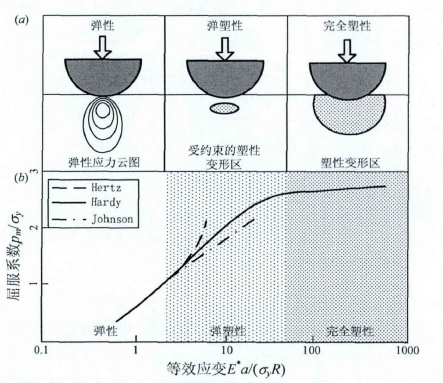

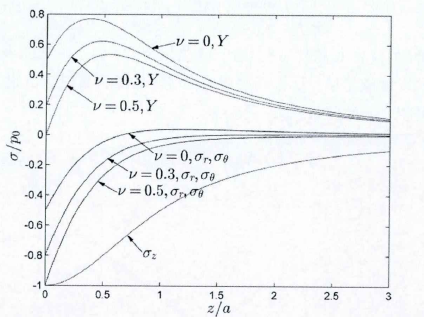

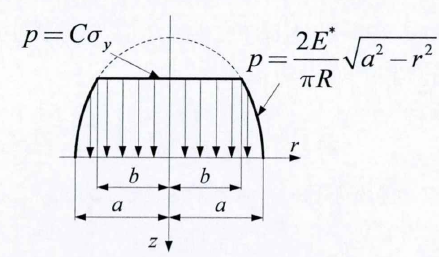

2.2 基于压痕理论对接触进行分析 9

2.3 量纲分析 12

2.3.1 量纲理论 12

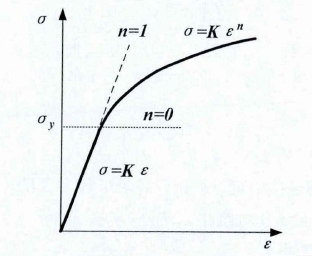

2.3.2 材料模型 14

2.4 压痕过程中的量纲分析 14

2.5 本章小结 16

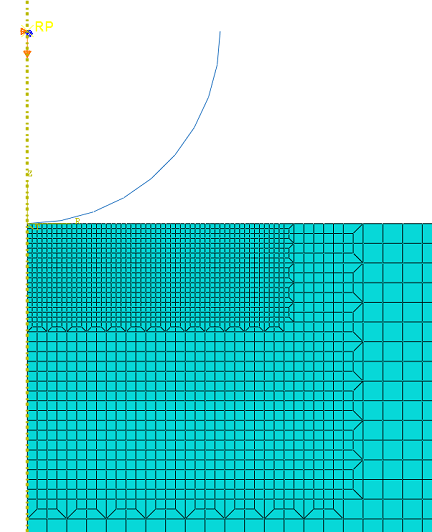

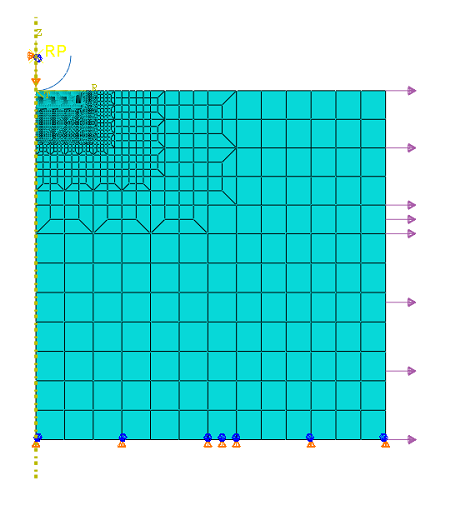

第3章 有限元的模型建立与分析 17

3.1 引言 17

3.2 有限元技术及其发展 17

3.3 有限元的模型建立 17

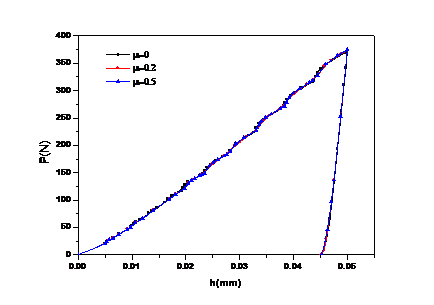

3.4 有限元模型的验证 19

3.4.1 摩擦接触行为对模型的影响 19

3.4.2 单元网格对模型的影响 20

3.5 本章小结 21

第4章 微载荷连续压痕测量残余应力的反演方法 22

4.1 引言 22

4.2 无量纲函数的数学表达 22

4.3 反演分析方法 24

4.4 模拟实验验证 25

4.5 本章小结 26

第5章 结论与展望 27

5.1 本文总结 27

5.2 展望 28

致 谢 29

参考文献 30

第1章 绪 论

1.1 课题意义

相关图片展示: