拱顶储罐设计研究毕业论文

2020-05-28 07:00:45

摘 要

石油作为最重要的化工原料之一,但由于其性质易燃易爆,所以在储运过程中危险性非常高,研究其安全储存问题一直以来备受工程师们的关注。拱顶罐作为最常见的原油储罐,设计更合理的储罐对化工企业的安全运行问题具有非常重要的意义。

本文针对拱顶储罐,以原油为储存介质设计一台储罐,包含罐壁、罐底、罐顶、附件以及校核等设计。本次设计主要采用文献法、经验总结法、计算验证法完成主要参数的设计。包括储罐的罐底直径和厚度,各圈罐壁板的厚度,罐顶的厚度及其失稳的计算,安全附件的选型,接管的开孔补强,法兰的选型等,并利用CAD绘制总图和各个部件的零件图。

本文主要的研究内容和结论主要如下:

- 本文对10000m³大型原油储罐的结构进行了全面的设计,主要以GB50341-2003《立式圆筒形钢制焊接油罐设计规范》为设计标准,对罐体的结构尺寸进行设计;

- 根据行业标准SY/T0511的规定,储罐的收发油流量取200

,设置一个DN200的呼吸阀,人孔以GB50341-2003《立式圆筒形钢制焊接油罐设计规范》为设计标准,公称直径为600mm;

,设置一个DN200的呼吸阀,人孔以GB50341-2003《立式圆筒形钢制焊接油罐设计规范》为设计标准,公称直径为600mm; - 基于SW6的计算,对筒体,上封头和开孔补强的进行强度校核,经过计算的出结果:筒体,上封头,开孔补强都是满足强度要求;

(4)根据失稳理论计算公式,分别计算出筒体失稳的临界压力为1336pa,封头失稳的临界压力为19911pa。故当储罐在呼吸阀阻塞或者操作不当时,先发生失稳的是筒体部分。

关键词:拱顶储罐 结构设计 强度校核 失稳计算

Abstract

Oil as one of the most important chemical raw materials, but because of the nature of the flammable and explosive, so in the storage and transportation in the process of risk is very high study the safety storage problem has attracted more and more engineers attention. Dome roof tank as the most common crude oil storage tank, more reasonable design of the storage tank of chemical enterprise safe operation problem has very important significance.

This paper for dome roof tank, using crude oil as a storage medium for design of a tank, including the tank wall and bottom tank, tank top, accessories and checking design. This design mainly uses the literature method, experience summary method, calculation verification method to complete the design of main parameters, including tank of tank bottom diameter and thickness, the thickness of the tank wall, the top of the tank thickness and the instability of the calculation, selection of safety accessories, the nozzle opening reinforcement, the flange of the selection and use of CAD drawing layout and the various components of the parts.

The main research contents and conclusions of this paper are as follows:

(1)The design of 10000m no large crude oil tank structure of comprehensive design, considering the wind load, hydraulic, the weight and pressure on the strength and stability of tank influence, mainly to GB50341-2003lt; vertical cylindrical steel welded tank design specification gt; as the design criteria of the tank structure size design.

(2)According to the provisions of the China petroleum natural gas industry standard SY/T0511-1996lt; oil tank breathing valve gt;, tanks and receiving oil flow from 200, setting a DN200 breathing valve and other accessories in accordance with the GB50341-2003lt; vertical cylindrical steel welded tank design specification gt; as the design criteria;

(3)Through the SW6 of the tank, head and opening reinforcement calculation, opening reinforcement is also consistent with the safety design. The results show that the design of large cylindrical vertical cylindrical storage tank structure size to meet the strength requirements;

(4) the critical pressure of the cylinder is 1336Pa, the critical pressure of the seal head is 19911Pa., so when the storage tank is blocked or the operation is not at that time, it is the cylinder part.

key word:;Dome roof tank;Structure design;Strength check;Instability calculation

目录

摘 要 I

Abstract II

第一章 绪论 1

1.1拱顶罐概述 1

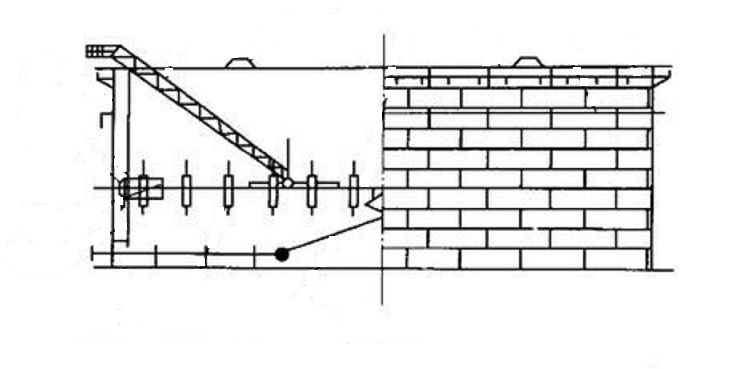

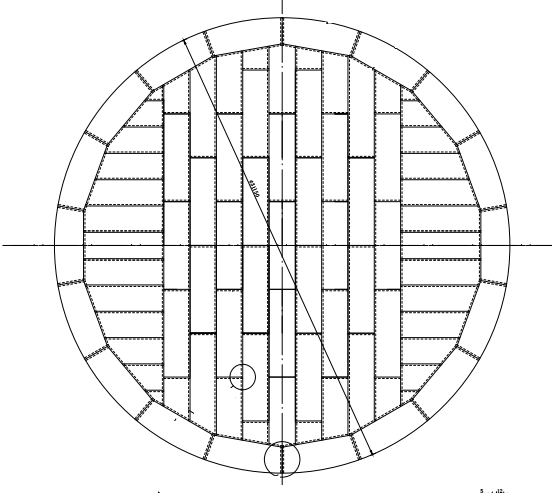

1.2拱顶罐的结构 3

1.3拱顶罐的发展方向 5

1.4近年来国内外关于储罐的研究现状 5

1.5本文研究内容 9

第二章 罐体的设计 11

2.1拱顶罐的几何尺寸选择 11

2.1.1高径比确定 11

2.1.2拱顶的曲率半径的确定 11

2.2罐底的设计 11

2.3罐壁设计 13

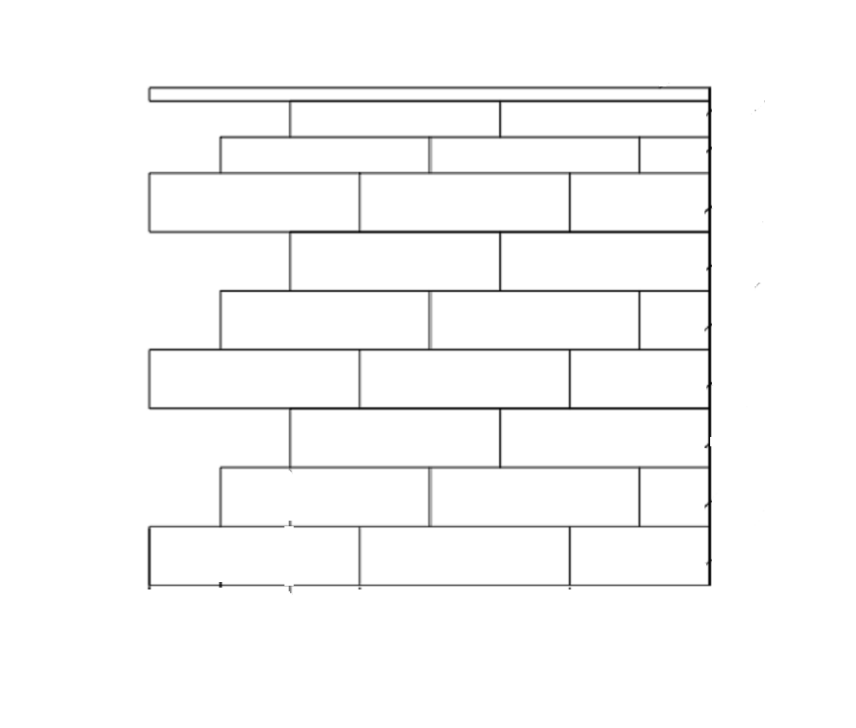

2.3.1罐壁钢板的尺寸和排板 13

2.3.2罐壁各层钢板厚度的计算 13

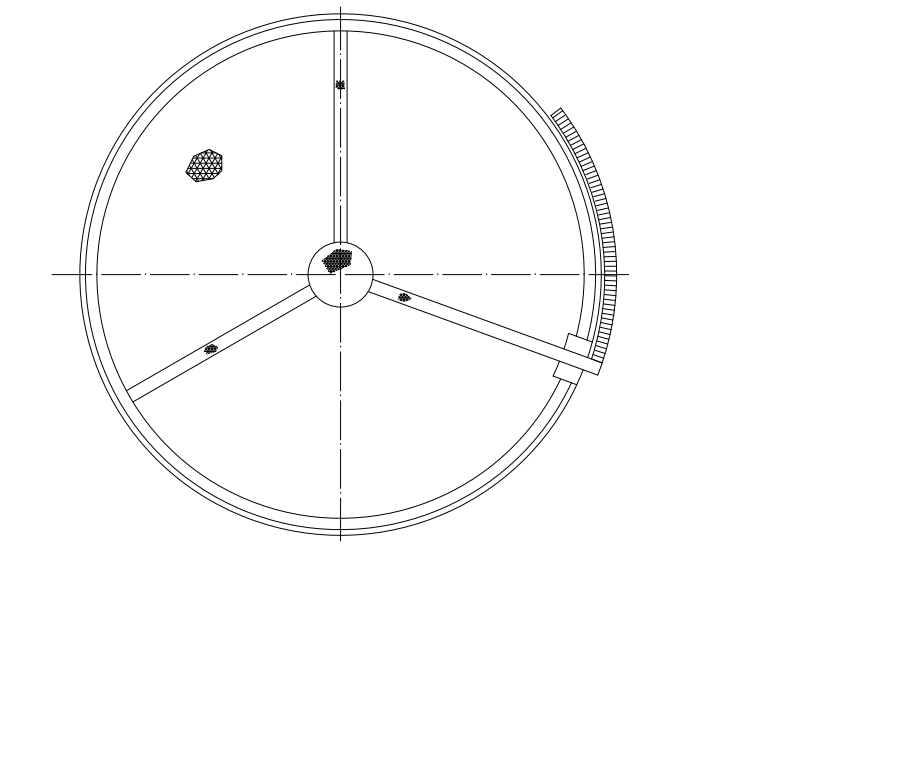

2.3.3罐壁包边角钢 17

2.3.4抗风圈设计 18

2.4固定顶设计 20

2.4.1球壳的设计厚度t选用: 20

2.5本章小结 20

第三章 附件的设计 22

3.1罐壁人孔 22

3.2清扫孔 24

3.3 罐顶人孔 27

3.4 排水槽 27

3.5 盘梯 28

3.6平台及护栏 28

3.7 透光孔 29

3.8罐壁接管 29

3.9 罐顶接管 31

3.10 呼吸阀 31

3.11本章小结。 32

第四章 校核 33

4.1软件介绍 33

4.2操作步骤 33

4.3计算结果 41

4.4本章小结 43

第五章 失稳计算 44

5.1筒体失稳 44

5.2罐顶失稳 45

5.3本章小结 47

第六章 结论与展望 48

6.1结论 48

6.2展望 48

参考文献 47

致谢 49

第一章 绪 论

1.1拱顶罐概述

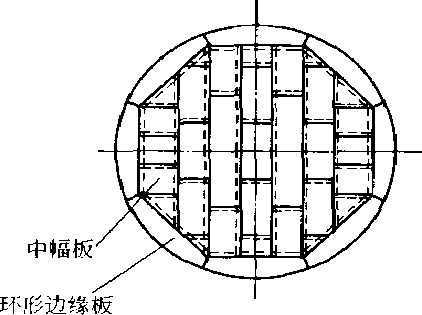

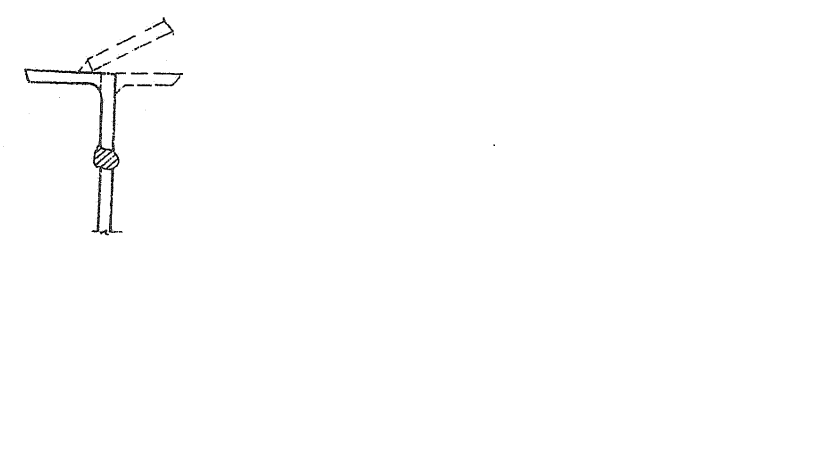

拱顶罐是化工行业中最常见的储罐之一,指储罐的罐顶为球形或者椭圆形,罐体为圆形柱体,罐底水平放置在地面上的储存容器。它的罐顶是由厚度不小于6mm钢板和加强钢焊接组成,或者由支撑桁架和钢板焊接组成。拱顶罐罐顶所受到的载荷可以通过拱顶周边传递到储罐的罐壁上,这种储罐的罐顶可承受较高的剩余压力,这样的设计有利于减少罐内液体介质的消耗。由基础、底板、壁板、顶板及油罐附件通过焊接或螺栓连接等方式组成了的储罐称为拱顶罐[1]。拱顶罐的罐壁和罐顶部位的结构制作简单,造价也比较低,只有罐顶由于结构的不同,制造稍微复杂。所以应用较为广泛。最常见的拱顶罐容积一般为为从1000到10000m³,也有个别特殊的大型拱顶储罐,拱顶储罐的最大容积为 30000m³。

最开始开发利用石油时,由于产量低。储油的设备极其简易,利用土坑、陶制品、皮囊、石器等容器储油。一直到19世纪70年代才采用钢材作为储油设备的材料,但最初的油罐容量也只有几升,几十升,不能满足工业的需求,通过几十年的慢慢发展,由几立方米到几百立方米。到了20世纪,工业飞速的发展,石油作为工业血液,需求量愈来愈大,石油的产量也越来越大,为了满足工业需求,各国都发展了大型油罐。随着制造业的发展,材料和制作工艺的进步,油罐的容量越做越大,经历了由小到大,从大到特大的历程[2]。

相关图片展示: