聚丙烯酸聚乙烯醇复合水凝胶的制备与性能研究毕业论文

2020-04-13 11:09:32

摘 要

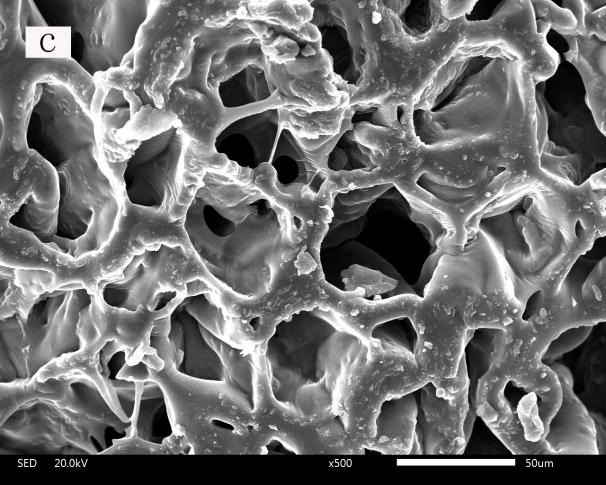

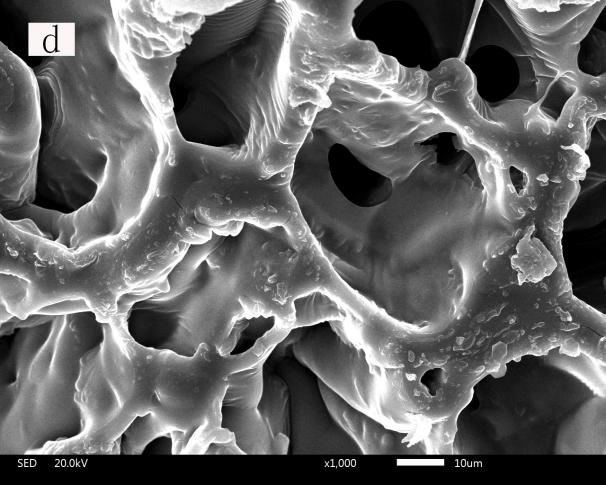

虽然传统的聚丙烯酸水凝胶拥有很好的吸液性能,但是由于缺乏力学强度的原因而使其应用受到了限制。本文探究了利用聚乙烯醇对聚丙烯酸水凝胶进行改性的制备方法并且讨论了不同工艺条件对其的影响。

本文以聚乙烯醇(PVA)和丙烯酸(AA)为原料,过硫酸铵(APS)为引发剂,N,N’-亚甲基双丙烯酰胺(MBA)为交联剂,采用化学交联的方法来制备聚丙烯酸/聚乙烯醇互穿网络水凝胶。另外,探究了聚乙烯醇用量(m(PVA):m(AA))、引发剂用量以及交联剂用量这三个因素对水凝胶吸水/吸盐水(0.9%)倍率的影响,并且研究了聚乙烯醇用量对水凝胶力学性能、保水性能的影响。

实验结果表明:聚乙烯醇的加入可以使保水率略有提升,并且能让力学强度大幅增加,并且在一定用量范围内使吸液能力增强,但是之后随其用量增加吸液能力会减小。实验结果表明,聚乙烯醇的加入能够使吸水倍率由263.0g/g提升至281.4g/g,将吸盐水倍率由34.4g/g提升至34.8g/g,将保水率由59.1%提升至64.2%,将抗压强度由3.5kPa提升至46.5kPa。而随着引发剂即过硫酸铵的用量增加,水凝胶的吸液倍率先增加后减小,最优提升至吸水倍率365.8g/g,吸盐水倍率47.8g/g。另一因素交联剂用量即N,N’-亚甲基双丙烯酰胺的用量增加,水凝胶的吸液倍率也是先增加后减小,最优提升至吸水倍率417.5g/g,吸盐水倍率50.7g/g。通过一系列平行实验,得到最佳的工艺条件为:m(PVA):m(AA)=5%,m(APS):m(AA)=1.5%,m(MBA):m(AA)=0.1%,在此条件下,产物水凝胶具有最大的吸水倍率417.5g/g,吸盐水倍率50.5g/g,力学强度为16.9kPa,保水率为62.3%,综合性能最优。

本文成功证明聚乙烯醇的加入对聚丙烯酸水凝胶的改性是很有效的,它能够将其力学性能大幅提高以适应更为广泛的应用需求,并且略微提升了保水率。另外这些实验的结果也证明了聚乙烯醇用量、引发剂用量、交联剂用量这三个因素对水凝胶的吸液能力都有很大的影响,适宜的用量能大大提高其吸水/吸盐水能力。

关键词:丙烯酸;聚乙烯醇;超吸水凝胶;力学性能

Abstract

Though the traditional polyacrylic acid hydrogels have excellent absorbing properties, their application has been restricted on account of the lack of mechanical strength. This article discusses the preparation of polyacrylic acid hydrogels using polyvinyl alcohol and explores the effects of different process conditions on them.

This paper elaborates how to use polyvinyl alcohol (PVA) and acrylic acid (AA) as raw materials, ammonium persulfate (APS) as an initiator, N,N'-methylenebisacrylamide (MBA) as a cross-linking agent to prepare polyacrylic acid/polyvinyl alcohol interpenetrating network hydrogels with the chemical crosslinking method. The effects of the amount of polyvinyl alcohol (m(PVA):m(AA)), the amount of initiator and the amount of cross-linking agent on water and brine(0.9%) absorption capacity, in the meantime,the effect of the amount of PVA on the mechanical properties and water retention properties of the hydrogel were investigated.

The results of these experiments showed that the addition of polyvinyl alcohol can slightly increase the water retention efficiency and significantly increase the mechanical strength, at the same time,it can increase the liquid absorption capacity within a certain range, but then decrease the liquid absorption capacity with the use of polyvinyl alcohol. The experimental data showed that the addition of polyvinyl alcohol can increase the water absorption ratio from 263.0 g/g to 281.4 g/g and the ratio of absorbed salt water from 34.4 g/g to 34.8 g/g, and it can also increase the water retention efficiency from 59.1% to 64.2% and increase the compressive strength from 3.5 kPa to 46.5 kPa. With the increase of the amount of the initiator, ie, ammonium persulfate, the liquid absorption ratio of the hydrogel first increases and then decreases, and it is optimally raised to a water absorption ratio of 365.8 g/g and a salt water absorption rate of 47.8 g/g. The other factor is the amount of cross-linking agent, ie, the amount of N,N'-methylenebisacrylamide used, the hydrogel absorption rate of the hydrogel is increased first and then decreased, and the water absorption rate is optimally raised from 417.5g/g to 50.7g/g.Through a series of parallel experiments, the best process conditions were obtained: m(PVA):m(AA)=5%, ω(APS)=1.5%, and ω(MBA)=0.1%. Under this condition, the largest water absorption rate of the product hydrogel was 417.5 g/g, the brine(0.9%) absorption rate was 50.5 g/g, the mechanical strength was 16.9 kPa and the water retention efficiency was 62.3%. The overall performance was optimal and the best operating conditions were obtained.

This paper successfully proves that the addition of polyvinyl alcohol is very effective for the modification of polyacrylic acid hydrogel because it can greatly improve its mechanical properties to meet a wider range of application needs. In addition, the results of these experiments also proved that the three factors of the amount of polyvinyl alcohol, the amount of initiator, the amount of cross-linking agent have a great impact on the hydrogel absorption ability, the appropriate amount can greatly improve its water / brine absorption capacity.

Key Words:acrylic acid;polyvinyl alcohol;superabsorbent hydrogel;mechanical properties

目 录

第1章 绪论 1

1.1 引言 1

1.2 PVA/PAA水凝胶的主要制备方法和研究进展 2

1.2.1 PVA/PAA水凝胶的合成制备方法 2

1.2.2 PVA/PAA水凝胶的研究进展 3

1.3 研究内容 4

1.4 预期目标 4

第2章 实验部分 6

2.1 实验仪器与试剂 6

2.1.1 实验主要仪器 6

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

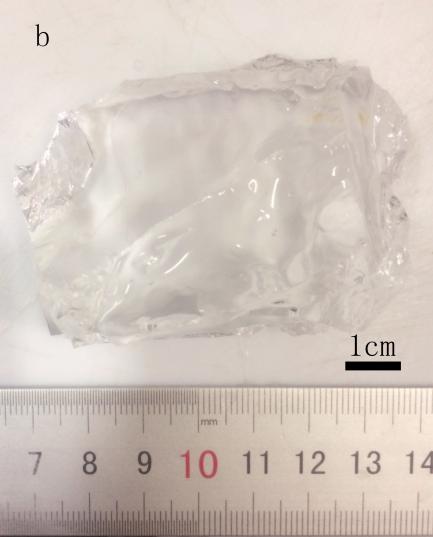

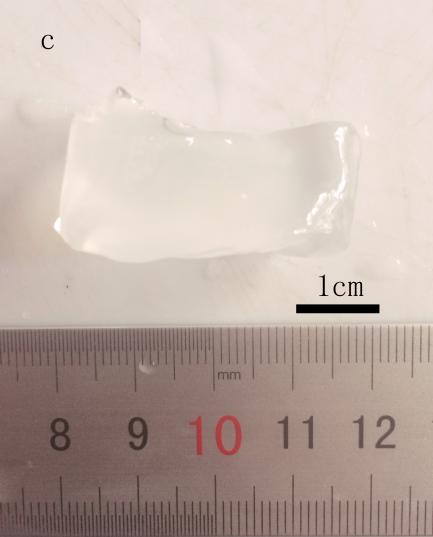

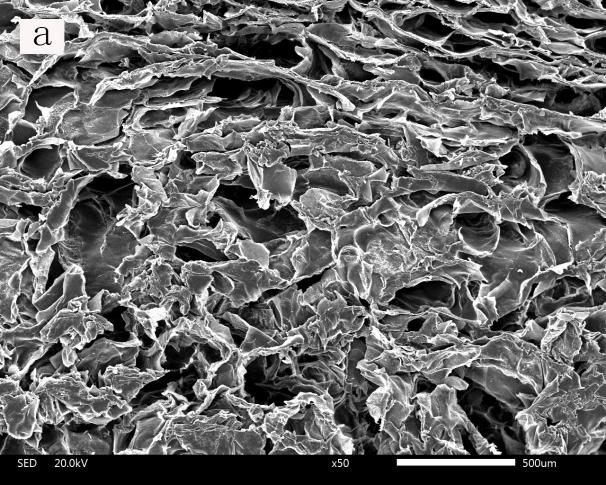

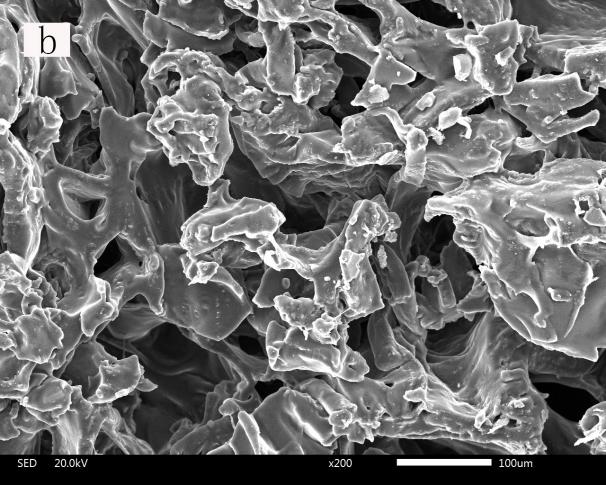

相关图片展示:

您可能感兴趣的文章

- 用于甲醇制烯烃反应的SAPO-34/ZSM-5复合催化剂的原位水热结晶合成外文翻译资料

- 硫化氢在活体的化学发光探针成像外文翻译资料

- 全色发射型ESIPT荧光团对某些酸及其共轭碱负离子识别的颜色变化外文翻译资料

- 一种用于成像神经元细胞和海马组织中NMDA受体附近内源性ONOO-的双光子荧光探针外文翻译资料

- 表面功能化的Ui0-66/pebax基超薄复合中控纤维气体分离膜外文翻译资料

- 金属有机框架中的可逆调节对本二酚/醌反应:固态固定化分子开关外文翻译资料

- 二维MXene薄片的尺寸相关物理和电化学性质外文翻译资料

- 将制甲烷的Co催化剂转化为产甲醇的In@Co催化剂外文翻译资料

- MXene分子筛膜用于高效气体分离外文翻译资料

- 模板导向合成具有排列通道和增强药物有效荷载的立方环糊精聚合物外文翻译资料