山东某造纸厂污水处理工程设计毕业论文

2020-07-11 17:59:59

摘 要

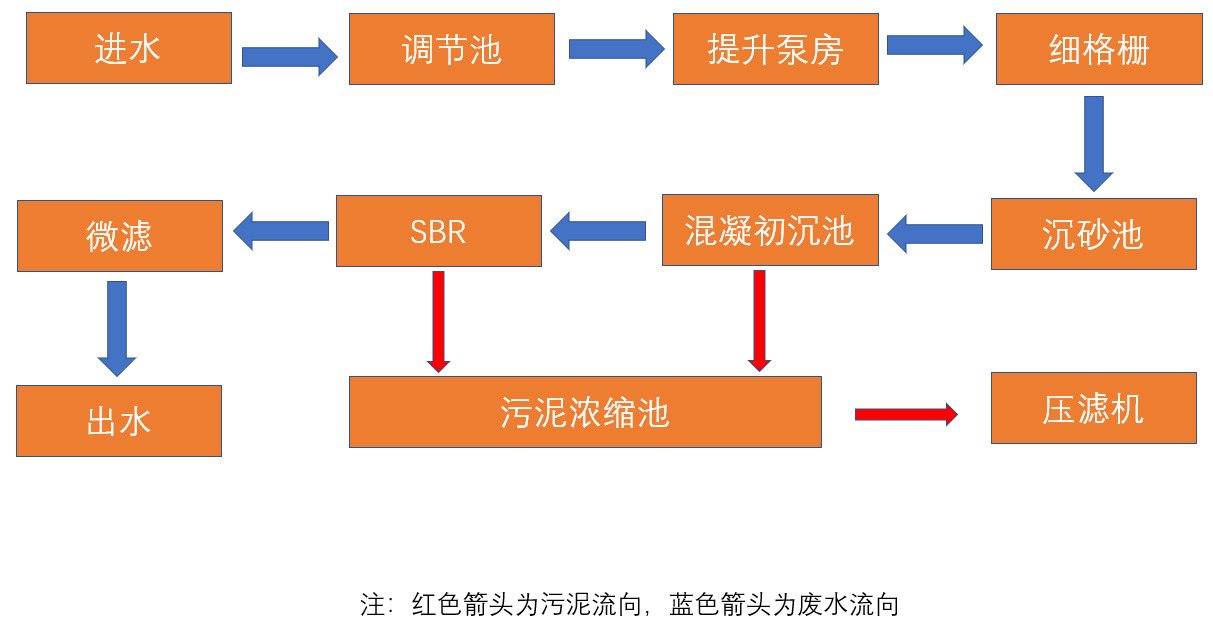

造纸工业是我国六大污染行业之一。造纸废液会对自然河流,微生物,动植物产生危害。本设计对造纸厂生产过程中产生的制浆废水的特性,用三种常用的水处理组合工艺进行比较,对三种组合工艺优缺点比较权衡,确认序批式活性污泥法为主要工艺对造纸废水进行处理设计。工艺流程为:格栅→混凝→SBR→微滤。污水处理后,达到工业回用水的回用标准,用于造纸厂的生产生活。

关键词:SBR工艺 造纸废水 混凝

Sewage treatment engineering design for a paper mill in Shandong Province with a total capacity of 10,000 t/d

Abstract

Paper industry is one of the six major pollution industries in China. Papermaking waste liquids can cause harm to natural rivers, microorganisms, animals and plants. This design compares the characteristics of the pulping wastewater generated in the paper mill production process with three commonly used water treatment combined processes, and compares the advantages and disadvantages of the three combined processes, confirming that the sequencing batch activated sludge process is the main process Papermaking wastewater treatment design. The process flow is: grid→coagulation→SBR→microfiltration. After the sewage treatment, the reuse standard of industrial reuse water is achieved for the production and life of the paper mill.

Key words:SBR process; Papermaking wastewater;Coagulation

目录

摘要······························································Ⅰ

Abstract···························································Ⅱ

第一章 综述

1.1 前言························································1

1.2造纸废水处理技术·············································1

1.2.1物理化学处理法·········································1

1.2.2生物处理法·············································3

1.2.3人工湿地法·············································5

第二章 编制依据和设计内容

2.1 设计内容····················································6

2.2设计基础资料·················································6

2.3设计依据、规范标准···········································6

2.4设计污水水质·················································6

2.5设计出水水质·················································7

2.6设计原则·····················································7

2.6.1 方案确定··············································7

2.6.2 设计计算···············································7

2.6.3 平面高程布置···········································7

2.6.4 编写设计说明书·········································7

2.7工艺说明与比选··············································7

2.7.1 三种组合工艺··········································7

2.7.2 组合工艺说明··········································8

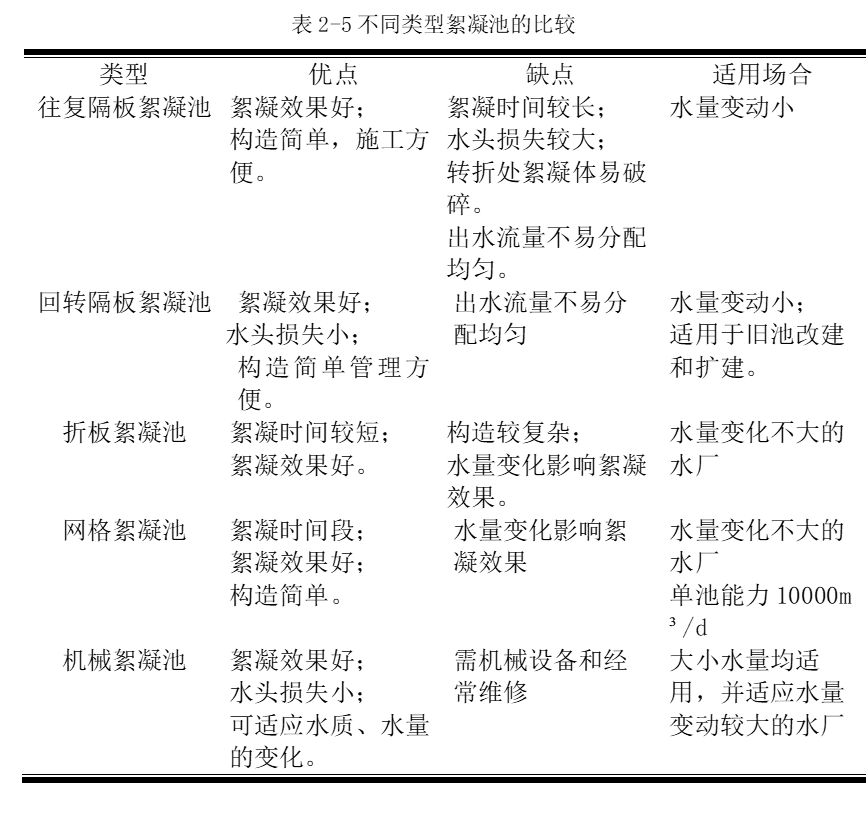

2.7.3 三种组合工艺比选······································9

2.8构筑物设计··················································10

2.8.1格栅··················································10

2.8.2沉砂池················································11

2.8.3药剂混合··············································12

2.8.4絮凝池················································13

2.8.5初次沉淀池············································14

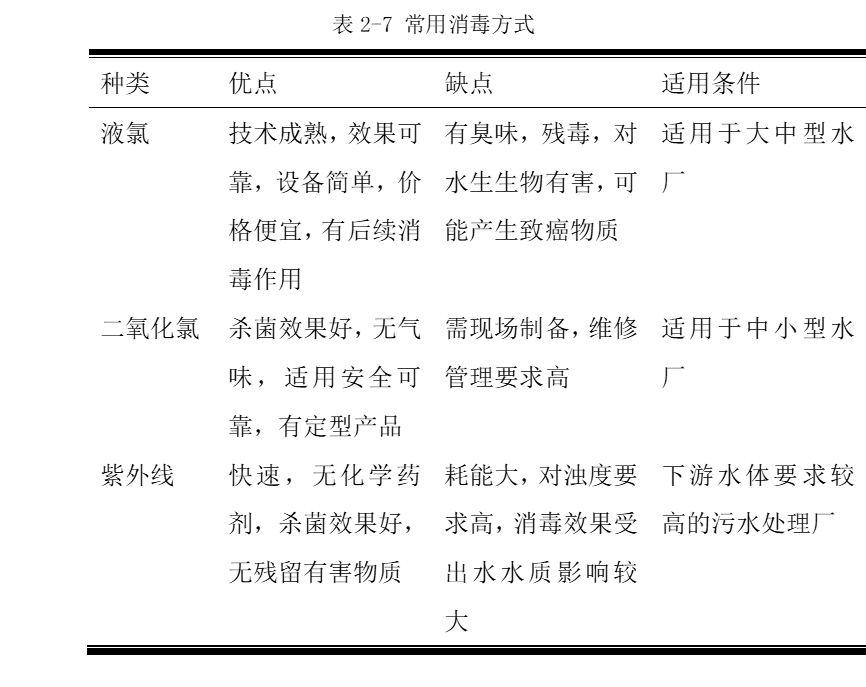

2.8.6消毒··················································15

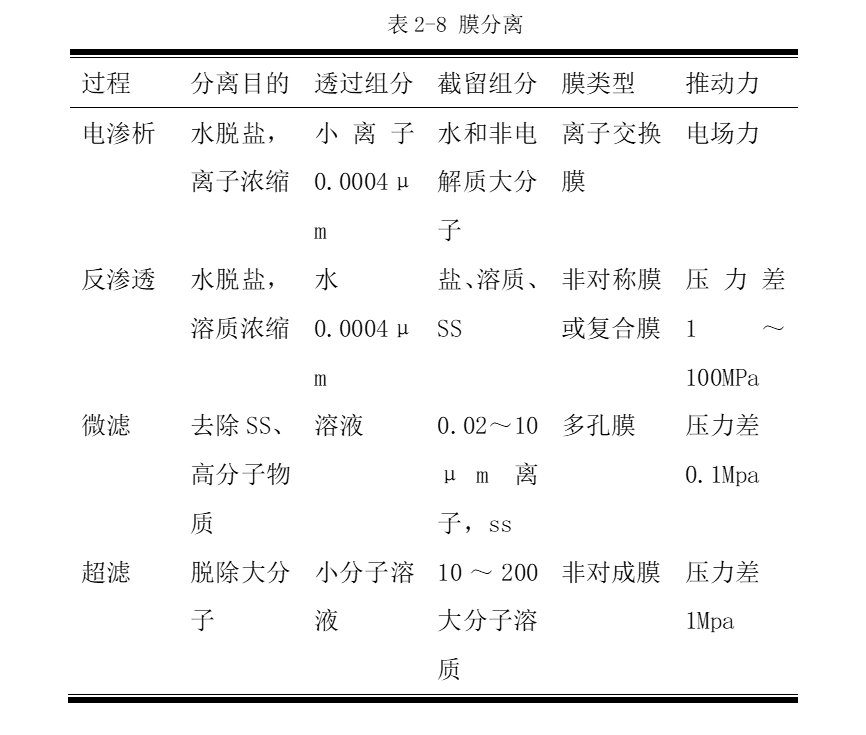

2.8.7膜分离················································16

2.9污水处理工艺流程图··········································17

第三章 设计水质水量及污水处理程度

3.1 设计水量···················································18

3.2 设计污水水质···············································18

3.3 污水处理程度计算···········································18

第四章 污水处理构筑物计算

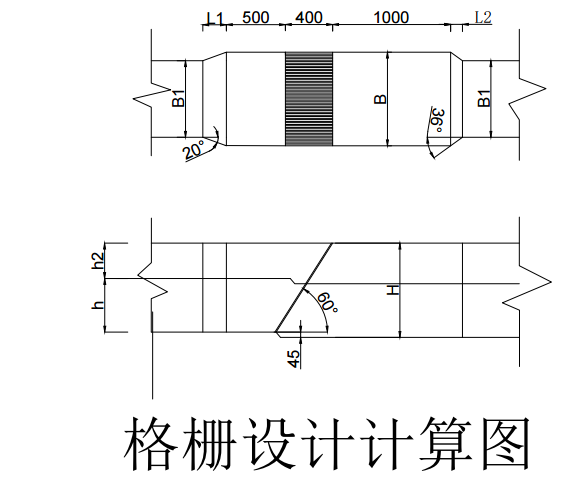

4.1 泵前格栅··················································20

4.2 调节池·····················································23

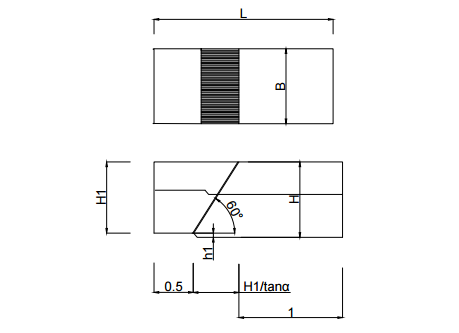

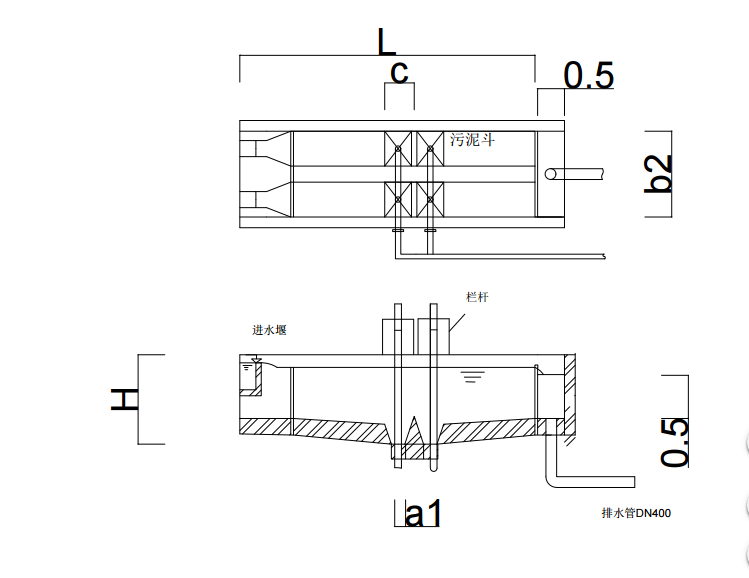

4.3 细格栅·····················································24

4.4 平流式沉砂池···············································27

4.5 药剂与投放装置·············································31

4.6 机械搅拌混合池·············································34

4.7 往复式隔板絮凝池···········································36

4.8 竖流式初次沉淀池···········································41

4.9 间歇式活性污泥法···········································45

4.10 污泥系统··················································50

4.11 竖流浓缩池················································51

4.12 贮泥池····················································55

4.13 污泥脱水··················································57

4.14 消毒池····················································58

4.15供氧设施··················································60

4.16 内压式微滤膜死端过滤······································63

4.17计量堰····················································68第五章 污水处理设施布置

5.1污水处理厂选择厂址的原则····································72

5.2污水处理厂的平面布置········································72

5.3平面布置的原则·············································72

5.3.1构筑物················································73

5.3.2管道平面布置··········································73

5.3.3厂区绿化··············································73

5.3.4道路布置··············································73

5.4高程布置···················································74

5.4.1高程布置的原则·······································74

5.4.2 高程计算·············································75

5.5污泥处理构筑物高程布置······································78

第六章 技术与经济分析

6.1经济核算····················································82

6.1.1经济核算原则··········································82

6.1.2一次性投资············································82

6.1.3运行成本估算··········································85

第七章 总结展望

7.1总结·······················································86

7.2展望·······················································86

参考文献·························································87

致谢······························································89

- 综述

1.1 前言

我国的造纸工业是世界上生产和贸易大国,造纸工业是国民经济的根底工业,是集合资金、技术、污染的重要工业。造纸废水其表征为水量大,化学需氧量高,拥有大量的悬浮物质,污染物的成分和结构复杂且可生化性低,在中国工业污水中属于最大的。需要对造纸废水进行深入研究和妥善的处理。

我国的造纸规模化程度低,对于环境保护不重视。现在我国对于环境污染越来越重视,需要造纸企业采用适当的工艺对废水进行处理或里哟个,以减少污染。

1.2造纸废水处理技术

造纸废水处理技术主要有物理化学、生物处理和人工湿地法。一、物理化学技术主要是联合物理方法和化学方法来去除水中杂质,其中物理方法用机械过滤,重力沉降等简单方式去除造纸废水中细小纤维、不溶性或大颗粒物质。常见方法有格栅、澄清池、砂滤池、膜分离、气浮、混凝等。化学方法是用化学试剂对废水中污染物发生化学反应,使之发生形态变化来将造纸废水中的可溶性物质、胶体物质去除。化学反应常见的表现形式有中和反应、还原反应、催化氧化、微电解等。二、生物处理技术是对微生物的新陈代谢对污水中的污染物进行转化和分解的一种污水净化方法。大致可以区分为微生物的好氧处理和厌氧处理两种方法。常用的污泥混合曝气法和生物膜法是好氧造纸废水的两种方法。常见非好氧生物处理技术有厌氧生物处理法和水解酸化法。三、人工湿地法是利用自然生态系统中物理、化学和生物的作用净化污水,如土壤过滤、微生物代谢、植物吸收分解等。

物理化学处理法是应用物理和化学综合作用使得废水净化的方法。用于造纸废水处理的主要有:格栅或筛网,混凝剂沉降,三相分离的气浮法,强氧化剂氧化分解有机物法,膜分离等技术。

- 混凝沉淀 气浮技术

造纸废水中存在可沉降和不可沉降悬浮物,为了保证后续单元的正常运行,通常使用混凝剂进行预处理沉降。一般选用聚合氯化铝(PAC)和聚丙烯酰胺(PAM)。陈涛等采用的混凝气浮-曝气生物流化床法处理造纸废水中,PAC和PAM在14ml/l 6ml/l时,COD去除率为41.3%,出水浓度为2079mg/l,,与后续的气浮技术联合,能够将化学需氧量去除达到40%,SS达到90%左右,为后续处理提供有利条件[4]。

相关图片展示: