电厂脱硫废水蒸发用烟气冷却器的设计毕业论文

2020-07-15 21:09:44

摘 要

近年来,随着国民经济的不断进步发展,对电力的需求变得越来越大,而燃煤发电是电力生产的主要途径,其设备机组的数量增长也越来越快,造成对燃煤的需求量大增,因此,与燃煤和全球性环境有关的问题越来越突出。在此背景之下,很多的火力发电厂研发投入了各自的的烟气脱硫系统,利用科学化的烟气脱硫技术合理控制处理硫氧化物实际排放情况,但是,传统脱硫工艺大部分情况下都是运用湿法脱硫方法来脱硫,因此会产生大量脱硫废水,并且废水中也有大量的重金属离子,废水未经处理直接排放会造成很严重的环境污染,这是我们不希望看到的。所以,现在社会应高度重视脱硫废水的处理问题,使废水达到排放要求后进行排放。

多效蒸发结晶系统顾名思义就是由多个蒸发器组成,连接方式为串联。对于电厂脱硫废水处理过程中烟气冷却器是利用锅炉排烟(作为加热段)的温度加热工质(水蒸气)来使冷却段中的脱硫废水中的水分经过多效蒸发,剩下结晶体来进行脱硫,用此种方法可以回收利用前端工艺产生的热量,减少冷端热损失,从而提高机组热效率,降低煤耗,达到节约能源的目的。

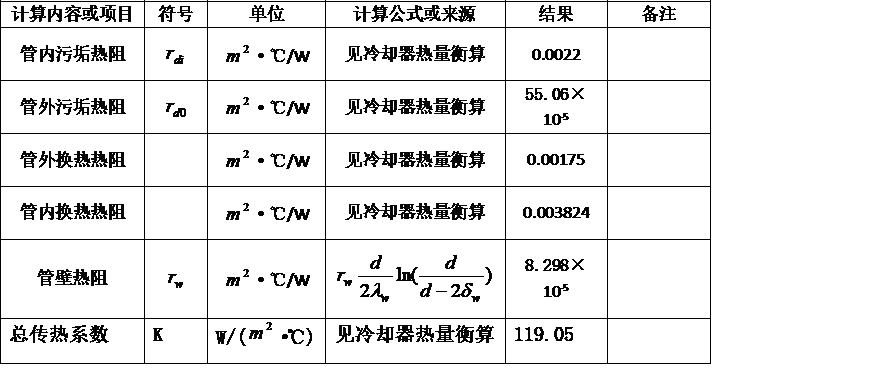

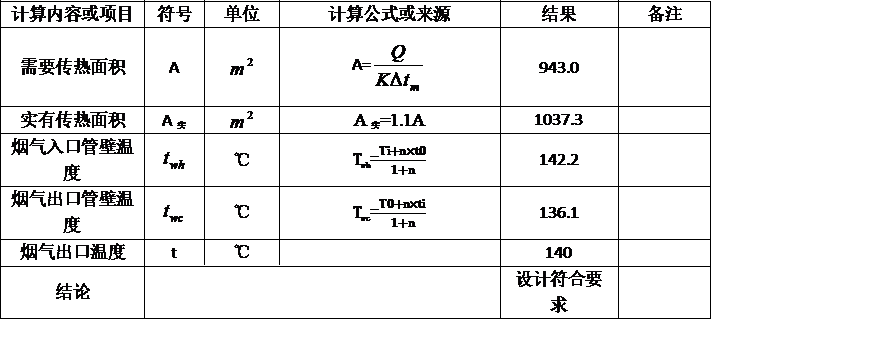

本文针对锅炉装置余热回收系统的特点,计算并且设计了电厂内脱硫废水蒸发用烟气冷却器的方案。并对冷却器进行了热平衡计算、总传热系数的计算、总传热面积的确定、阻力计算,以及强度校核计算。并绘制了整体系统的布置图、设备图和零件图。

关键词:省煤器 烟气冷却 余热 烟气冷却器 节能

Abstract

In recent years, with the continuous progress of national economy, demand for electricity becomes larger and larger, while coal fired power generation is the main way of electricity production. Therefore, problems related to coal combustion and global environment are becoming increasingly prominent. Under this background many thermal power plants have invested their flue gas desulfurization systems and controlled effectively sulfur oxides actual emissions using scientific flue gas desulfurization technology however the flue gas desulfurization system was controlled reasonably by thermal power plants. Traditional desulfurization processes are mostly desulfurization by wet desulfurization process thus producing lots of wastewater containing desulfurization wastewater and lots of heavy metals ions in wastewater which can cause serious environmental pollution due to untreated wastewater treatment without treatment. That's what we don't want to see. Therefore, society should attach great importance to treatment problem of desulfurization wastewater, so that wastewater can be discharged after discharge requirement.

Multi-effect evaporation crystallization system consists of several evaporators which consist of series of evaporator. Heating steam is used as secondary steam of prior evaporator and heating chamber of next evaporator is used as cooler of previous evaporator. Flue gas cooler is used to heat refrigerant (steam) by heating steam in boiler exhaust gas (as heating section) during desulfurization wastewater treatment process so that moisture in flue gas desulfurization wastewater can be evaporated through multi-effect and then crystallization is used to desulfurization. Using this method can recover heat generated by front end process reduce heat loss of cold end thereby improve thermal efficiency reduce coal consumption and achieve energy saving purposes.

Aiming at characteristic of boiler equipment waste heat recovery system, this paper calculates and designs scheme of flue gas cooler used for desulfurization wastewater evaporation in power plant. Heat balance calculation total heat transfer coefficient calculation of total heat transfer area calculation of resistance calculation and strength checking calculation were carried out. Drawing up layout plan equipment diagram and drawing parts of whole system..

Key words: Economizer Flue gas cooling Residual heat Flue gas cooler Energy saving

目录

摘要 1

Abstract 3

第一章 绪论 7

1.1换热器 7

1.2省煤器 7

1.3 小结 9

第二章 烟气冷却器的热力计算 10

2.1安装位置的设计 10

2.2 设计方案 10

2.3 初始数据 10

2.4热平衡计算 11

2.5 总传热系数的计算 12

第三章 阻力计算 17

3.1 烟气流动阻力计算 17

3.2换热器水侧阻力 17

第四章 换热器段工艺计算 19

4.1明确设计任务 19

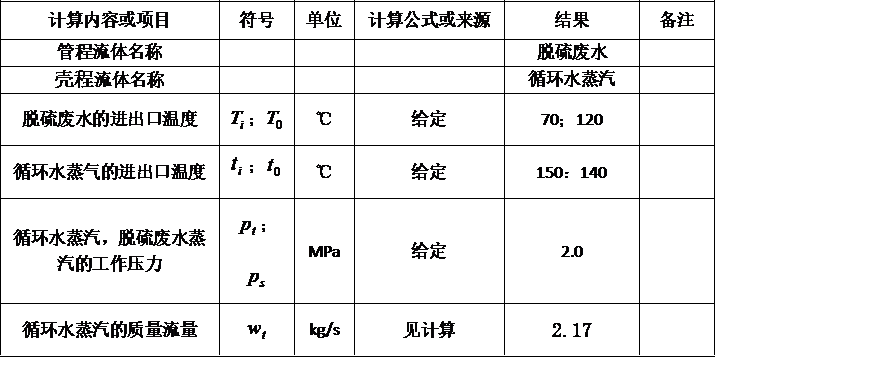

4.2 原始数据 19

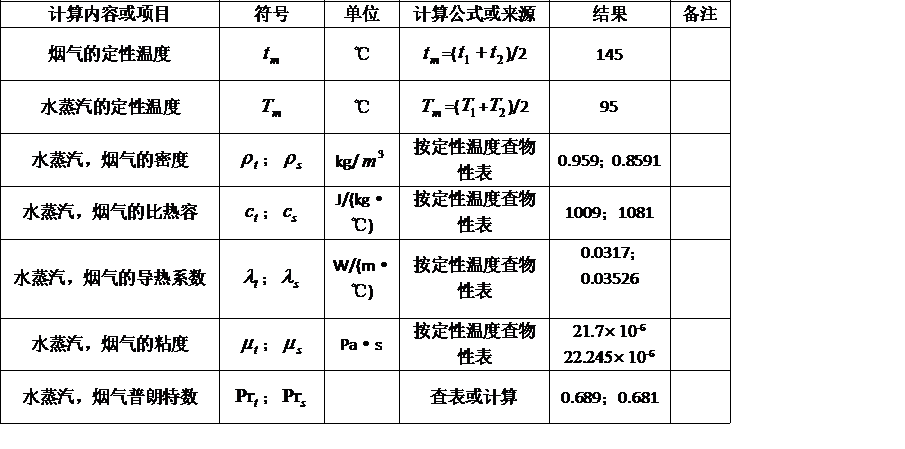

4.3 定性温度与物性参数 19

4.4物料与热量衡算 20

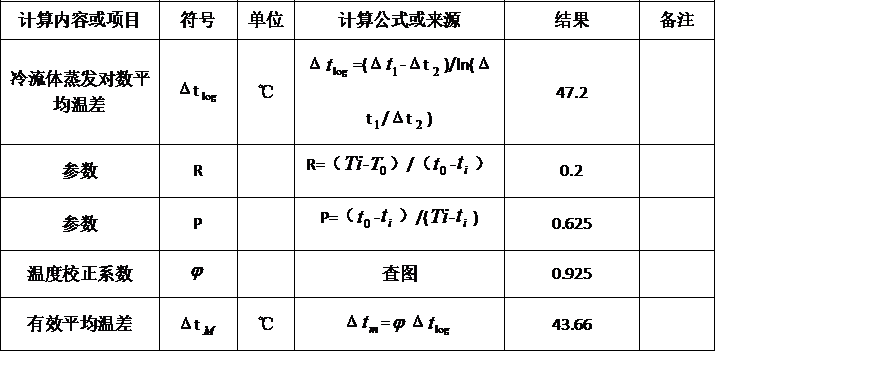

4.5有效平均温差 20

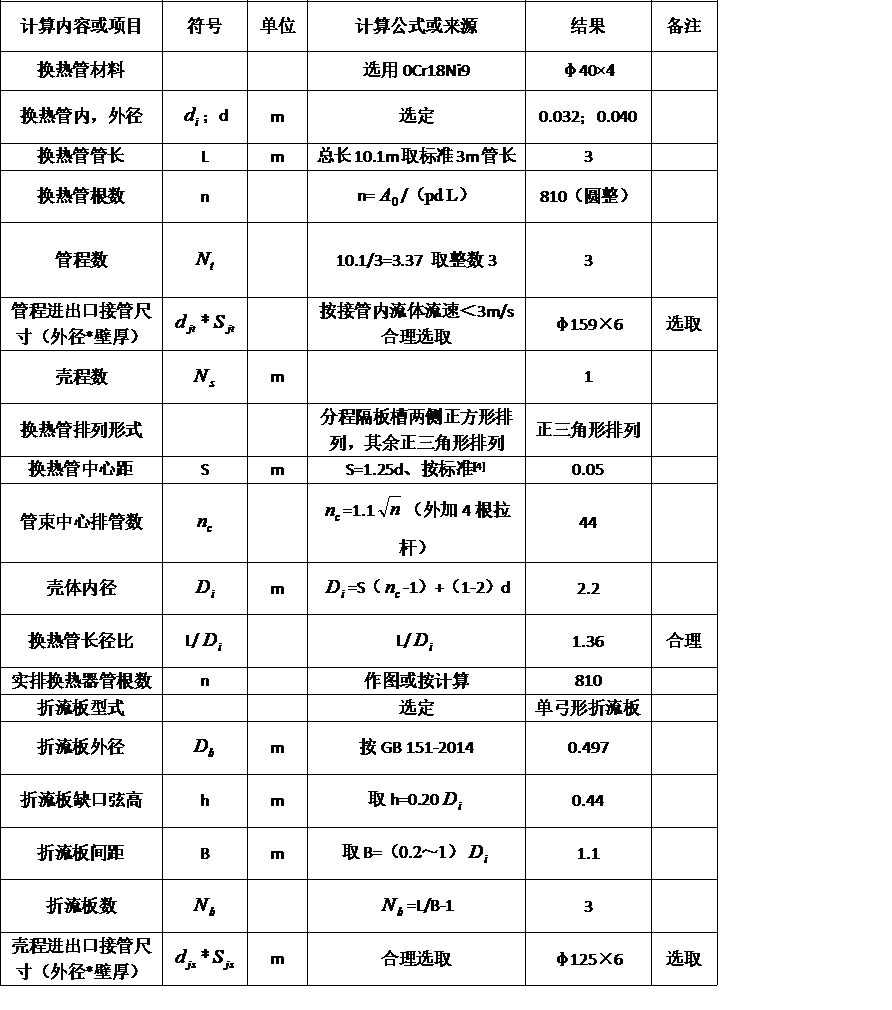

4.6 换热器结构计算 21

4.7 总传热系数 22

4.8传热面积与壁温核算 22

第五章 节能效益分析 23

5.1等效标煤量Gc 23

5.2增加的能耗 23

第六章 结语 25

6.1 结论 25

6.2 展望 25

参考文献 26

致谢 28

附录 sw6校核 29

第一章 绪论

1.1换热器

1.1.1研究换热器的重要性

在工业生产中,换热器的作用是用来将一种流体的热量通过某种传热方法传递给其他流体。在换热器内,参与传热的流体最少有两种,并且他们的温度也各不相同。一种高温流体放出热量,另一种低温流体吸收热量。

使用方面:

换热器被广泛应用在工业生产中。在大部分生产领城中,为了使能源被充分利用,达到节能减排的目的,热交换过程必须通过换热器来利用和回收余热,这些方面都促进了热交换器的设计和发展。

根据热交换器在的设计应满是多种多样工艺上的的要求,下面列出了设计过程中的四种基本要求:

(1)工艺过程提出的基本要求要满足。例如设计的换热器热交换强度必须要高,设计在有利的平均温差下,另外还要热损失少。

(2)工艺结构使用时必须不容易被破坏,必须适应温度和压力条件,设计时还要满足经济效益高,运行安全等条件,

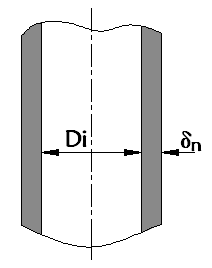

相关图片展示: